Synthetic Roofing Underlayment: Surpassing Tradition and Leading the New Trend in Roof Protection

On the stage of building roof protection, a transformation between traditional and synthetic roof underlayments is quietly taking place.

Recently, after visiting numerous construction enterprises and building materials markets, journalists found that synthetic roof

underlayments are gradually surpassing traditional ones with their unique advantages and becoming the new favorite in roof

protection. Among them, the MOUNTAIN BIGFOOT BARRIER synthetic underlayment stands out particularly.

Traditional roof underlayments once occupied an important position in the construction field. However, with the development of

construction technology and the improvement of people's requirements for roof quality, their shortcomings have become increasingly

obvious. Traditional underlayments are mostly made of natural fibers or asphalt-impregnated materials, and their waterproof performance

is limited. Once there is water accumulation on the roof or it is washed by rain for a long time, they are prone to becoming saturated with

water, resulting in the failure of the waterproof function. Moreover, their physical properties are relatively weak, and they perform poorly in

terms of tensile strength and tear resistance, and are easily damaged during the construction or use process.

The MOUNTAIN BIGFOOT BARRIER synthetic underlayment has brought innovative solutions. It adopts advanced polymer alloy technology

and has excellent waterproof performance. Its waterproof principle is to design a special molecular structure so that water cannot penetrate

the underlayment, thus ensuring that the roof remains dry all the time. In terms of mechanical properties, it has high strength and high

toughness and can withstand relatively large external forces without being damaged. During the construction process, its flexibility and

portability enable it to easily adapt to various roof shapes and complex construction environments, significantly improving the construction

quality and efficiency.

In addition, the MOUNTAIN BIGFOOT BARRIER synthetic underlayment has good weather resistance and anti-aging properties and can

work stably for a long time under various harsh climate conditions. In contrast, traditional underlayments are prone to aging and

embrittlement when exposed to natural environments such as sunlight, wind, and rain for a long time, and need to be maintained and

replaced frequently.

Market feedback shows that many construction enterprises have a preference for the MOUNTAIN BIGFOOT BARRIER synthetic

underlayment, relying on its performance advantageRIER synthetic underlayment. Although its price is slightly higher than that of

traditional underlayments, considering the long-term use cost and the roof protection effect, it undoubtedly has a higher

cost-performance ratio.

All in all, the MOUNTAIN BIGFOOT BARRIER that surpass traditional ones, is leading the new trend in roof protection, building a more

solid protection barrier for the quality and durability of building roofs and promoting the construction industry to move to a new height

in the field of roof protection.

2024-12-19

DETAIL

Bigfoot Roof Underlayment: Long-lasting Protection with Worry-free Extended Service Life

In numerous construction projects, the durability of roofs has always been a key consideration. Thanks to

its innovative material formula and advanced manufacturing process, Bigfoot Roof Underlayment has

demonstrated outstanding performance in practical applications.

Extensive field tests and long-term monitoring data have shown that under normal usage conditions,

Bigfoot Roof Underlayment can easily withstand the dual challenges of the passage of time and harsh

weather, and its projected service life far exceeds the average level of similar products. Whether it's

exposure to scorching sun, torrential rain, or alternating bouts of severe cold and intense heat, Bigfoot

Roof Underlayment always stays on duty, effectively protecting the integrity of the roof structure and

greatly reducing risks such as roof leakage and damage caused by the aging of the underlayment,

thus providing a durable and stable protective barrier for buildings.

Roofing worker Andrew said in an interview, "Throughout my many years of work experience, I've been

extremely impressed by the durability of Bigfoot Roof Underlayment. It's not only easy to install but also

has stable performance during long-term use. It has significantly reduced the frequency of roof maintenance

and replacement. In the long run, it has noticeably cut down construction costs and is an ideal material for

improving the overall quality and lifespan of buildings."

As the construction industry's demand for high-quality, long-life building materials continues to rise,

Bigfoot Roof Underlayment undoubtedly precisely meets this market trend. Its excellent performance

in terms of service life not only provides solid and reliable roof solutions for various construction projects

like commercial buildings and residential projects but also injects powerful impetus into promoting the

entire construction industry to move towards greater durability, environmental friendliness, and higher

efficiency.

2024-12-19

DETAIL

The Development History of Roof Underlayment: From Tradition to Modern as a Building Waterproof Shield

The early roof underlayment can be traced back thousands of years ago when people began to attempt to protect their living places from

the wind and rain using various natural materials. In ancient civilizations such as ancient Egypt and ancient Greece, people constructed

simple roof structures with materials like mud, reeds, and wood, and applied a layer of mud or asphalt on the surface to achieve a

preliminary waterproof effect. These early attempts, although simple, were the prototypes of roof underlayment development and laid the

foundation for subsequent technological evolution.

As time passed, during the Middle Ages, European builders started to use materials such as wooden boards, slate, and tiles to build more

solid and durable roofs. Among these roof structures, animal furs, wool fabrics, and oiled paper were used as underlayment to enhance

waterproof performance. The use of these natural materials improved the waterproof effect of the roof to a certain extent, but their

durability and waterproof performance were still limited and required regular replacement and maintenance.

The arrival of the Industrial Revolution brought about a huge transformation in roof underlayment technology. In the mid-19th century,

with the large-scale production of industrial materials such as rubber and asphalt, roof underlayment began to enter the modern

development stage. Rubber underlayment, with its excellent elasticity and waterproof performance, quickly became a popular choice

and was widely used in the roof waterproofing projects of various industrial and commercial buildings. At the same time,

asphalt-impregnated felt mats also emerged. This material, by impregnating the felt with asphalt, had good waterproofness and durability

and became one of the main materials for roof underlayment of residential buildings at that time.

In the early 20th century, the rapid development of the petrochemical industry further promoted the innovation of roof underlayment

technology. Plastic materials such as polyethylene (PE) and polypropylene (PP) began to be applied in the manufacturing of roof

underlayment.

In recent years, a new synthetic material, MOUNTAIN BIGFOOT BARRIER, has emerged, and its unique properties have brought new

breakthroughs to roof underlayment. This integration has significantly improved the waterproofness, durability, and resistance to

extreme environmental conditions of roof underlayment. These plastic underlayments have the advantages of being lightweight,

corrosion-resistant, easy to process and install, and have gradually replaced the traditional rubber and asphalt underlayments,

becoming the mainstream materials for roof waterproofing in modern architecture. In addition, with the continuous update of

architectural design concepts, the functions of roof underlayment are no longer limited to waterproofing but also begin to have

multiple functions such as heat insulation, sound insulation, and fire prevention.

Today, roof underlayment has become an essential part of modern architecture. It not only plays a crucial role in protecting buildings

from the wind and rain. With the continuous progress of science and technology and the sustainable development of materials science,

it is believed that roof underlayment technology will embrace an even more glorious future, creating more comfortable, safe, and

sustainable living environments for humanity.

2024-12-18

DETAIL

Insight into the Consumption Popular Trends in the Roof Underlayment Market: Driven by Innovation, Diversified Demands Lead the New Direction

With the continuous development of the construction industry and the increasing demands of consumers for housing quality,

the roof underlayment market is undergoing profound changes and innovations. As a crucial component in the roof system,

roof underlayment not only provides basic waterproof and moisture-proof functions for buildings, but also its performance in

aspects such as materials, properties, and environmental protection has attracted more and more attention from consumers,

showing a series of notable consumption popular trends.

1. Sustainable Materials Are Favored and the Concept of Environmental Protection Is Deeply Rooted in People's MindsAgainst the backdrop of the continuous strengthening of global environmental awareness, consumers attach greater importance

to the environmental protection attributes of roof underlayment products. More and more builders and property owners tend to

choose roof underlayment made of sustainable materials, such as recycled fiber materials and biodegradable materials. During the

production process, these environmentally friendly materials can significantly reduce the consumption of natural resources and the

emissions of greenhouse gases. They not only conform to the current development concept of green buildings but also help to

improve the overall sustainability evaluation of buildings. According to industry data, the market share of environmentally friendly

roof underlayment products has been growing steadily in the past few years and is expected to maintain a strong upward trend in

the future.

2. The Demand for High-Performance Products Has Surged to Meet the Challenges of Extreme WeatherIn recent years, extreme weather events, such as heavy rainstorms, hurricanes, and blizzards, have occurred frequently, putting

forward higher requirements for the waterproofing, windproofing, and durability of roof systems. Therefore, roof underlayment

products with excellent performance have become the new favorites in the market. Consumers are more willing to invest in

purchasing underlayment materials with high waterproofing, high strength, tear resistance, and good air permeability to ensure

that the roof can still maintain stable and reliable performance under harsh weather conditions. For example, some new

high-performance synthetic material underlayments can have a waterproof performance several times that of traditional asphalt

underlayments. Meanwhile, they also possess outstanding tensile resistance and puncture resistance, which can effectively resist

the damage to the roof caused by natural disasters such as strong winds and hailstorms.

3. The Rise of Personalized Customization to Meet Diverse Aesthetic NeedsIn addition to the requirements for functions and performance, consumers have a higher pursuit for the appearance

design of roof underlayment. Personalized customized roof underlayment products are gradually becoming popular

in the market and can meet the diverse needs of different architectural styles and consumers' personal preferences.

From coatings with rich colors to surface treatments with unique textures, to customized pattern printing, roof

underlayment is no longer limited to the traditional monotonous appearance but has become a part of the overall

aesthetic design of buildings. Builders and decoration companies are also paying more and more attention to

communication and cooperation with clients in the design of roof underlayment to create unique roof decorative effects.

This trend has promoted roof underlayment manufacturers to innovate and upgrade their product design and production

processes to meet the growing personalized customization needs in the market.

2024-12-17

DETAIL

Synthetic Roof Underlayment Installation: Focus on Problems and Solutions

In roofing projects, the installation of synthetic roof underlayment is of crucial importance, yet there are numerous issues that demand

immediate attention.

Recently, some construction projects have encountered problems such as leaks and wrinkling of the underlayment after the installation

of synthetic roof underlayment. According to professional analysis, this is often closely related to the non-standard operations during the

installation process. Many construction workers fail to accurately measure the roof dimensions during installation, resulting in improper

cutting of the underlayment and loose edge sealing, which leaves potential risks for rainwater leakage. At the same time, some

underlayments are not fully laid considering the roof slope and drainage direction during the installation process, causing water

accumulation areas. Long-term immersion damages the performance of the underlayment.

However, among numerous synthetic roof underlayment products, the MOUNTAIN BIGFOOT BARRIER synthetic underlayment shows

good performance in installation. It has clear and definite installation markings, facilitating construction workers to determine the cutting

position and laying direction. Moreover, the material of this underlayment has a certain degree of flexibility and self-adhesiveness,

enabling it to better conform to the complex shape of the roof during laying and reducing the occurrence of wrinkling. Even in some

special roof structures, such as those with a large number of ventilation ducts, chimneys and other obstructions on the roof, the

MOUNTAIN BIGFOOT BARRIER synthetic underlayment can also successfully complete the installation by virtue of its good plasticity,

effectively ensuring the waterproofness and integrity of the roof.

The construction industry should attach great importance to the installation problems of synthetic roof underlayment, strengthen the

professional training of construction workers and standardize the installation process. And products like the MOUNTAIN BIGFOOT

BARRIER that have advantages in installation can also provide useful references and examples for the industry, jointly promoting

the improvement of roofing project quality and safeguarding building safety.

2024-12-17

DETAIL

Synthetic Underlayment Technology: Innovative Changes in Roof Protection

Recently, the construction industry has witnessed a major breakthrough. The emergence of the new synthetic underlayment

technology has provided a more excellent solution for roof protection.

Traditional roof underlayment materials have gradually revealed many limitations during long-term use. For example, traditional

asphalt felt underlayment is easily affected by climate changes. It may crack and age under high-temperature exposure, which

greatly reduces its waterproof performance. In a low-temperature environment, it will become brittle and the risk of damage will

increase. Moreover, its service life is relatively short, usually requiring replacement within 5 to 10 years. Frequent replacements

not only consume manpower and material resources but may also cause potential damage to the roof structure during the

construction process.

The new synthetic underlayment, on the other hand, demonstrates significant advantages. It is mainly made of advanced

polymer materials, such as polyethylene, polypropylene or polyvinyl chloride, etc., and special components like anti-ultraviolet

additives are added. These polymer materials endow the underlayment with excellent flexibility and weather resistance, enabling

it to maintain stable performance under various harsh climate conditions. The anti-ultraviolet additives effectively slow down

the aging speed of the material caused by sunlight exposure and greatly extend its service life, which is expected to reach 10

to 20 years or even longer.

In terms of waterproof performance, the synthetic underlayment forms an efficient waterproof barrier by virtue of its dense

material structure and special coatings. Whether it is a torrential rain or the melting of ice and snow, it can effectively prevent

water from infiltrating into the interior of the roof and protect the integrity of the building structure. Meanwhile, its good tear

resistance, especially the addition of reinforcing materials such as glass fiber or polyester fiber in the reinforced synthetic

underlayment, has greatly improved the underlayment's ability to resist external forces during installation and use, reducing

the risk of damage caused by construction operations or extreme weather.

Currently, numerous construction enterprises have begun to actively adopt this new technology and apply it widely in residential

and commercial building projects. From pitched roofs to flat roofs, the synthetic underlayment can perfectly match various roofing

materials, providing all-round, long-lasting and reliable roof protection for buildings. It is expected to become the mainstream

choice for future roof protection projects and promote the construction industry to develop in a more efficient and durable direction.

2024-12-16

DETAIL

Roof Synthetic Underlayment: Defending Against Storms and Guarding the "Backbone" of the Home

In the current era of frequent storms, the protection of roofs has become a focus of concern for many homeowners. Traditional

roof protection measures often have numerous limitations, and the emergence of roof synthetic underlayment is bringing a

brand-new ray of hope to solve this problem.

Compared with traditional asphalt paper underlayment, roof synthetic underlayment has outstanding performance advantages.

It is made of advanced polymer composite materials and has excellent waterproof properties. It can effectively prevent rainwater

from penetrating and ensure that the interior of the roof remains dry even under the long-term assault of violent winds and

heavy rains. In terms of wind resistance, this synthetic underlayment performs remarkably. The special material and structural

design enable it to closely adhere to the roof surface, forming a stable protective layer, which greatly enhances the roof's ability

to resist strong winds and effectively reduces the risk of tiles or other roofing materials being lifted by the wind.

A professional building engineer said: "During the inspections of houses after many storms, it was found that the structural

integrity of the roofs of houses with roof synthetic underlayment installed was significantly better than those with traditional

underlayment. Its protective effect on the roof is remarkable, which can effectively reduce roof damage caused by storms,

thereby reducing repair costs and property losses of the houses."

In practical applications, the installation of roof synthetic underlayment is also relatively convenient. A construction worker

said: "It can adapt to roofs of various shapes and slopes. The laying process is relatively simple, which can improve construction

efficiency. And during the installation process, it is not easily damaged and can well ensure the integrity of the protective

performance."

With the continuous development of building technology and the increasing demands of people for house protection,

roof synthetic underlayment is gradually becoming a new favorite in roof protection. With its excellent waterproof,

wind-resistant and other properties, it builds a solid defense line for the roof in the face of storms and plays an

irreplaceable important role in protecting the safety of the house and reducing property losses caused by storms.

For the vast number of homeowners, choosing roof synthetic underlayment is undoubtedly adding a sense of security

to their own homes and keeping the home stable as usual in the wind and rain.

2024-12-14

DETAIL

Protecting the Lifespan of Roofs: Useful Tips Revealed

The roof, as the "protective umbrella" on top of a building, directly affects the overall stability and safety of the building. Recently,

authoritative building experts have shared a series of useful tips for extending the lifespan of roofs.

Regular and meticulous inspections are essential. Experts suggest conducting two comprehensive inspections of the roof every year. Pay

close attention to whether there are cracks, gaps, blisters or missing parts in the roofing materials. Meanwhile, make sure that the roof

drainage system operates smoothly and that the gutters and downspouts are neither blocked nor damaged. Timely detection and handling

of these minor flaws can effectively avoid serious leakage problems that may occur later and prevent the roof structure from being corroded

by moisture.

Keeping the roof clean is a crucial part. Leaves, branches, dust and various debris that stay on the roof for a long time will absorb

moisture, breed mold and gradually erode the roofing materials. It is recommended to clean the roof regularly with a soft brush or a

blower. Especially after autumn and when strong winds pass by, timely cleaning can keep the roof in good condition.

It is of great significance to properly trim the branches near the roof. The lush branches are likely to scrape the roof surface in windy and

rainy weather, causing damage to the material surface. They may also serve as a passage for animals to access the roof, resulting in

damage such as gnawing and nesting. Regular pruning to keep a safe distance between the branches and the roof can reduce such risks.

Proper installation and maintenance of roof accessories are vital. Components such as solar panels, vents and chimneys can easily

become channels for rainwater leakage if the sealing is not good or there are gaps during installation. High-quality sealing materials

must be used during installation, and the sealing status should be checked regularly. If necessary, reseal them in a timely manner.

The choice of high-quality materials and professional construction teams is of utmost importance. When building a new roof or renovating

an existing one, the MOUNTAIN BIGFOOT BARRIER roofing underlayment is worth considering first. Its excellent anti-weathering and

anti-corrosion abilities can build a solid protective foundation for the roof. Professional construction teams can ensure that the roof

installation process meets the standards and avoid shortening the lifespan of the roof due to construction defects.

By following these practical tips, the costs of roof repair and replacement can be greatly reduced, making the building durable and stable

and creating a comfortable living and using environment for people.

2024-12-14

DETAIL

Roof underlayment flame retardant technology: Strengthening the fire protection barrier of buildings

In the field of building materials, the flame retardant technology of BIGFOOT roof underlayment provides a reliable solution for

improving building fire safety.

The flame retardant properties of BIGFOOT roof underlayment rely on the carefully developed material formula and advanced

manufacturing processes. In a professional flame retardant testing environment, this underlayment demonstrates excellent fireproof

performance. When exposed to a fire source, it can react quickly, effectively suppressing the rapid spread of flames and reducing

the speed of heat transmission, thus decreasing the possibility that a fire will spread throughout the entire building through the roof.

Test results show that compared with ordinary roof underlayments, BIGFOOT roof underlayment can significantly reduce the flame

spread rate, creating more favorable conditions for firefighting and rescue operations.

This flame retardant effect is due to both high-quality fireproof materials and its rational structural design. The fireproof fibers

inside the underlayment are intertwined with each other, constructing a solid heat insulation network and enhancing the blocking

efficiency against flames and heat. Whether it is commercial buildings, industrial facilities or residential houses, BIGFOOT roof

underlayment can serve as an effective fire protection line. For example, in a certain commercial building project, even when a

fire occurred in the surrounding area, BIGFOOT roof underlayment effectively resisted the encroachment of the flames, preventing

the further spread of the fire and ensuring the orderly evacuation of people inside the building and the safety of important materials.

In view of the growing emphasis on fire safety in the construction industry, BIGFOOT roof underlayment has emerged as the

times require. With its flame retardant advantages, BIGFOOT roof underlayment will gain more recognition in the building

materials market, promoting continuous progress in the roof underlayment industry in the field of fire safety and playing an

active role in safeguarding lives and property.

2024-12-13

DETAIL

MOUNTAIN BIGFOOT BARRIER: The Guardian of Roofs in Extreme Weather

Nowadays, extreme weather occurs frequently, posing a severe challenge to building roofs. The synthetic roof underlayment

named MOUNTAIN BIGFOOT BARRIER has emerged as a new hope for buildings to withstand strong winds and heavy rains.

Traditional roofing materials are extremely vulnerable in extreme weather. Violent winds can easily damage tiles and roofing

rolls, leading to damage to the roof and allowing rainwater to pour in, which may cause problems like water leakage in walls

and the collapse of ceilings. This brings huge economic losses to property owners and even poses a threat to people's lives.

However, MOUNTAIN BIGFOOT BARRIER performs outstandingly. It combines high-strength synthetic fibers with weather-resistant

polymers, possessing both flexibility and tensile strength. When strong winds strike, even extremely powerful winds can't lift it up.

It adheres closely to the roof base, dispersing the wind force and safeguarding the integrity of the roof. Its waterproof performance

is even more remarkable. The surface treated with a special process forms a dense waterproof layer. Facing torrential rains or a large

amount of accumulated water, it acts like a solid barrier, keeping the interior dry without any leakage.

During a super typhoon that hit the coastal area once, many buildings were severely damaged, while those equipped with

MOUNTAIN BIGFOOT BARRIER remained intact. Local residents were deeply grateful for it as it played a huge role at a critical

moment. Moreover, it has excellent durability and stability. It can resist the erosion of ultraviolet rays, acids and alkalis, maintaining

its performance over a long period, prolonging the service life of the roof and reducing the costs of maintenance and replacement.

Due to its outstanding performance, MOUNTAIN BIGFOOT BARRIER has won the favor of builders and property owners. An expert

in the construction industry commented, "It is an ideal solution to cope with extreme weather and promotes the improvement of

the quality of roofing projects. It plays a crucial role in ensuring the safety of buildings and will continue to shine in the construction

field in the future." It is certain that it will demonstrate its strength in more buildings and safeguard the safety of buildings in the future.

2024-12-13

DETAIL

Synthetic Roofing Underlayment: The Rise and Prospect of a New Favorite in Building Waterproofing

In the vast field of building materials, synthetic roof underlayment is gradually emerging and becoming the focus of the industry. With

its unique performance advantages, it is playing an increasingly important role in roof protection projects, providing a strong guarantee

for the durability and safety of modern buildings.

The reason why synthetic roof underlayment is favored by many lies primarily in its outstanding waterproof performance. Compared with

traditional roof underlayment materials, it can form a tighter and continuous waterproof layer, effectively preventing rainwater from

penetrating. Thanks to its special polymer material structure, it can firmly lock in moisture whether it's a downpour or a drizzle, ensuring

that the roof remains dry. Among them, BIGFOOT MOUNTAIN BARRIER stands out with its advanced technology and special molecular

materials, demonstrating unique excellence in waterproof performance. It can easily withstand the tests of extreme weather conditions

such as heavy rain and heavy snow, building a super-strong waterproof barrier for the roof of buildings.

In terms of durability, synthetic roof underlayment also performs excellently. It has excellent ultraviolet resistance and can maintain

stable performance under long-term direct sunlight without being prone to aging or cracking. Its weather resistance enables it to

adapt to various harsh climate conditions, whether it's freezing cold, sweltering heat, or wind and sand erosion. Having undergone

strict accelerated aging tests and on-site application monitoring under different climate conditions, BIGFOOT MOUNTAIN BARRIER

can effectively reduce the consumption of manpower, materials, and financial resources during long-term use.

The convenience of installation is also a highlight of synthetic roof underlayment. It usually comes in the form of rolls, which are

lightweight and easy to transport and lay. Construction workers only need simple training to quickly complete the installation work

according to standardized procedures. This not only shortens the construction period of the building and improves work efficiency

but also reduces potential risks caused by overly long construction time, such as the impact of weather changes on unfinished roofs.

Moreover, BIGFOOT MOUNTAIN BARRIER is designed with a unique splicing structure, making it extremely easy for construction

workers to operate and further increasing the installation speed. It shows significant advantages in large projects and lays a solid

foundation for the early completion of the entire project.

In addition, synthetic roof underlayment also has positive significance in terms of environmental protection characteristics. Some products

are recyclable, which makes them stand out among numerous roof underlayment materials in today's context where resources are

increasingly scarce and environmental protection requirements are becoming stricter.

Currently, the attention of many construction enterprises and developers to synthetic roof underlayment continues to rise. Some well-known

enterprises have already begun to widely apply it in projects such as high-end residences, commercial complexes, and industrial buildings.

In the future, with the deepening of research and development, synthetic roof underlayment is expected to be further optimized in

performance and more competitive in cost, thus occupying a larger share in the roof underlayment market and bringing higher-quality,

more efficient, and more environmentally friendly roof protection solutions to the construction industry. And excellent products like

BIGFOOT MOUNTAIN BARRIER will continue to lead the innovation and development of the industry, promoting building roof protection

technology to a new level.

2024-12-12

DETAIL

Innovation in Synthetic Liner Technology: Reshaping Roof Protection

In the continuous exploration for high-quality materials in the construction industry, the significant breakthrough in synthetic

liner technology is completelytransforming the way of roof protection. With its outstanding performance and wide adaptability,

it has already become a core highlight in the field of roofengineering and is leading the industry's protection standards to a

new height.

In terms of waterproof performance, its dense molecular structure forms a solid defense line. Even in extremely harsh situations

like torrential rain and severe wateraccumulation, the roof can still remain intact and leak-free. Laboratory and actual engineering

tests have shown that the waterproof effect of the new synthetic linerhas been significantly improved compared to that of

traditional liners, remarkably reducing the risks of building structure damage and indoor property losses causedby water leakage.

Currently, the construction industry attaches great importance to construction efficiency and cost control, and the convenient

installation characteristics of syntheticliner technology are highly favored. The lightweight design reduces the burden of transportation

and handling and cuts down labor and material costs. Its good flexibility and adaptability can perfectly match various complex roof

shapes, enabling construction workers to complete the laying quickly and easily and significantly shortening the construction period.

At present, synthetic liner technology has been widely applied in numerous projects such as high-end residences, commercial

complexes, and industrial buildings,and the market feedback is good. Leading enterprises in the industry continue to increase

their investment in research and development, strive to optimize the technology, and expand the application scope, so as to

create a safer, more comfortable, and more durable building space for the public.

2024-12-12

DETAIL

BIGFOOT 15

Learn More

BIGFOOT 15

Learn More

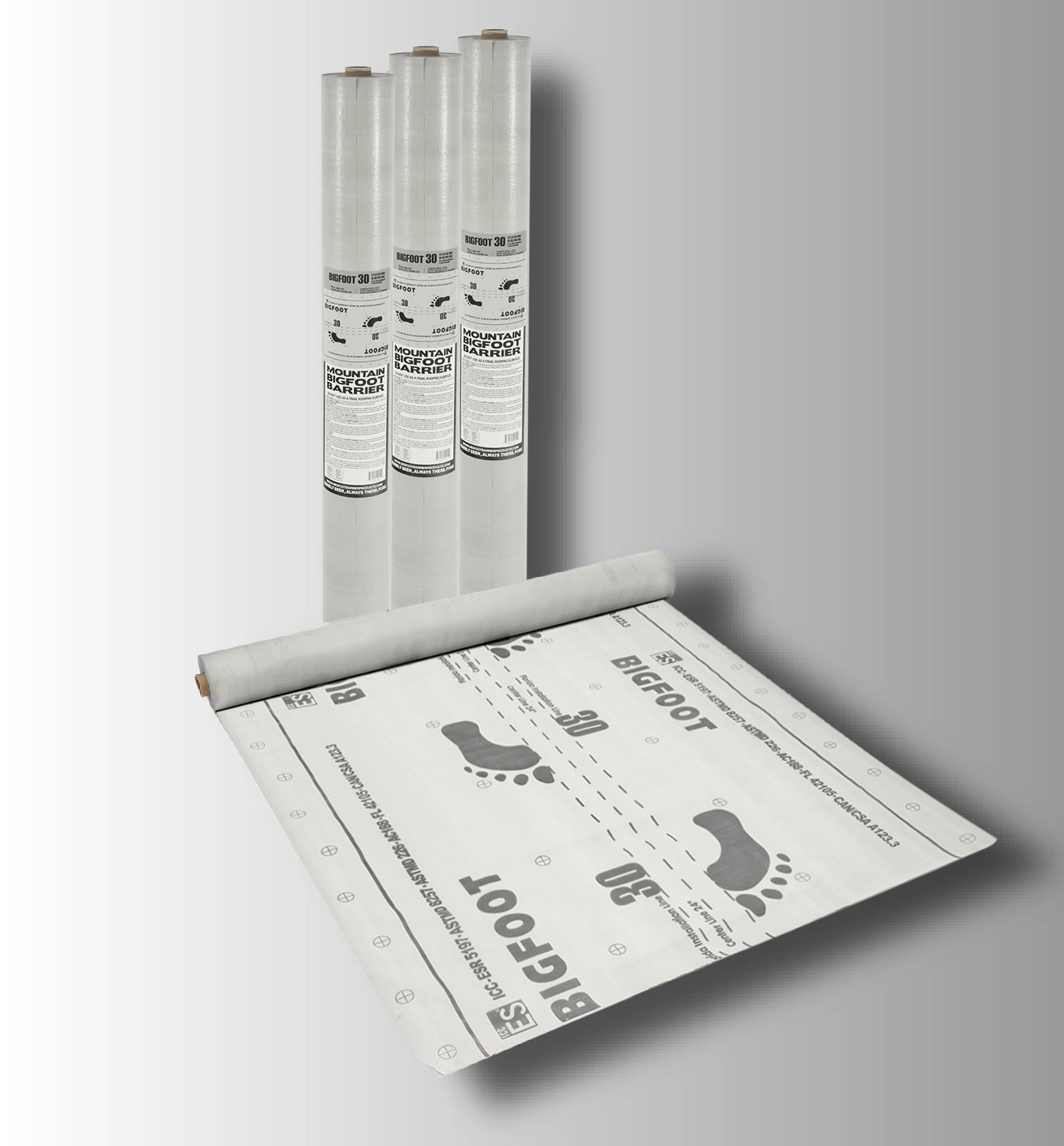

BIGFOOT 30

Learn More

BIGFOOT 30

Learn More

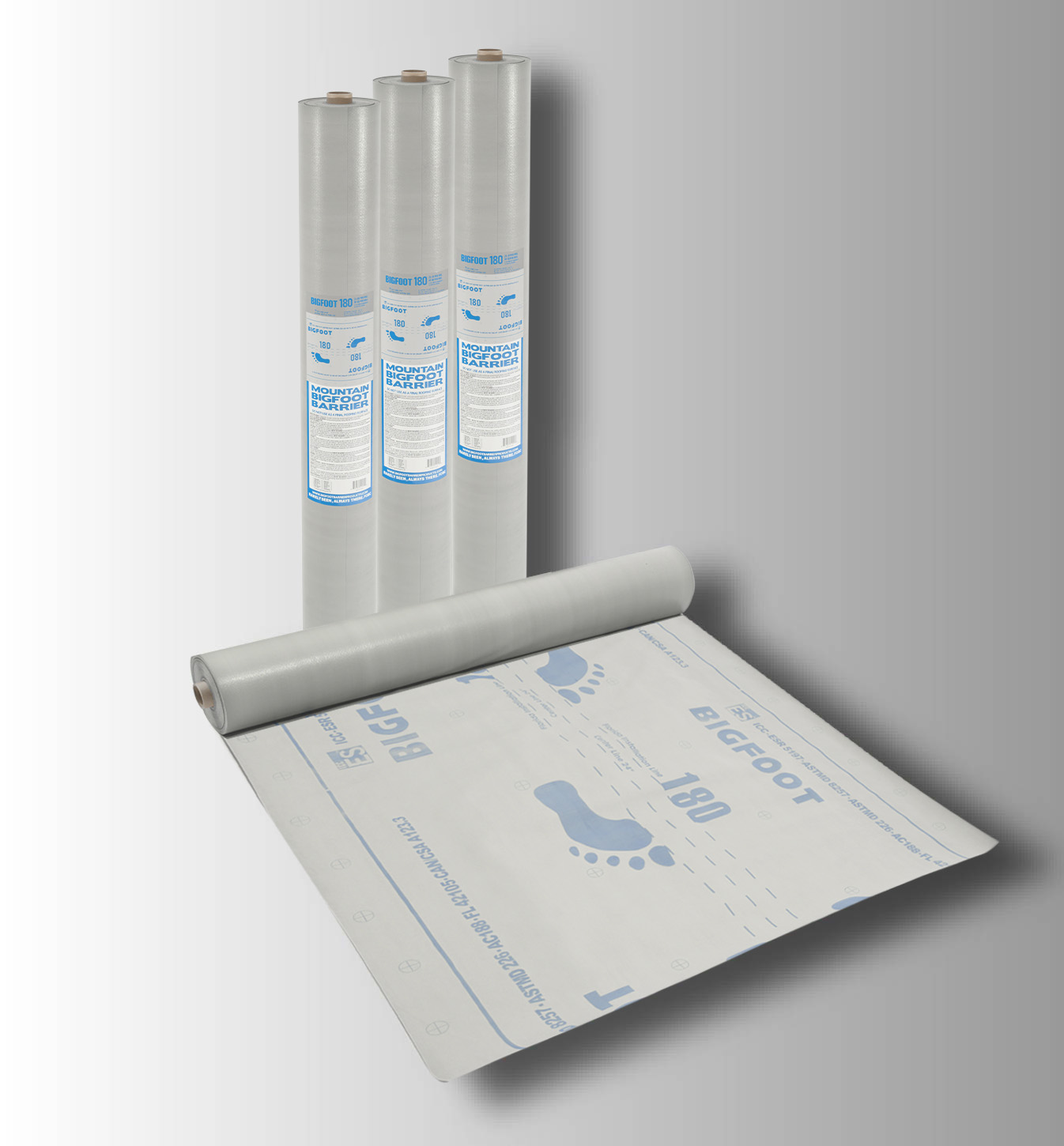

BIGFOOT 180

Learn More

BIGFOOT 180

Learn More

BIGFOOT HD

Learn More

BIGFOOT HD

Learn More

BIGFOOT 15

BIGFOOT 15

BIGFOOT 30

BIGFOOT 30

BIGFOOT 180

BIGFOOT 180

BIGFOOT HD

BIGFOOT HD

Back

Back