Ushering in a New Era of Low - Cost and High - Value Roofs

In the field of roofing materials in the construction industry, a quiet revolution is taking place. As a powerful alternative to traditional

asphalt felt, roof synthetic underlayment is rewriting the rules of cost - effectiveness and value enhancement for roofs with its superior

performance.

Although the price of synthetic roof underlayment is slightly higher than that of traditional asphalt felt during initial procurement and

installation, its huge advantages throughout the entire roof life cycle make it a highly cost - effective choice in the eyes of many building

owners and developers.

Reducing Repair and Maintenance Costs: Creating a "Zero - Burden" Roof

The excellent waterproof performance of synthetic roof underlayment is the key to reducing maintenance costs. Its tight material structure

effectively reduces leakage points and greatly reduces the risk of leakage. According to industry data, the repair frequency caused by roof

leakage in buildings using synthetic roof underlayment is approximately 70% lower than that in buildings using asphalt felt. This means a

significant reduction in labor costs and the material costs required for repairs. Moreover, due to the reduction in leakage, the interior

decoration, insulation layer, and structural components below the roof are better protected, avoiding damage caused by water

penetration and further saving potentially high repair costs. Many commercial buildings that have adopted synthetic roof

underlayment have hardly required large - scale roof repairs in the ten years since they were put into use, achieving an almost

"zero - maintenance" ideal state.

Strong Durability: Extending the Service Life of the Roof

Synthetic roof underlayment performs remarkably in withstanding harsh environments. It can effectively resist the erosion of ultraviolet

rays and will not age rapidly due to long - term sun exposure like traditional asphalt felt. At the same time, it also has good adaptability

to drastic temperature changes and will not crack due to thermal expansion and contraction. In extreme weather conditions such as strong

winds and heavy rains, its tough material can remain stable and is not easily torn. This excellent durability significantly extends the service

life of the roof. Taking residential buildings as an example, the service life of roofs using synthetic roof underlayment can reach 25 years or

even longer. In contrast, traditional asphalt felt roofs usually only last for 10 - 15 years, thus saving property owners huge expenses for

multiple roof replacements in the long run.

Increasing Property Value and Living Comfort: Dual Benefits

From the perspective of the real estate market, properties with synthetic roof underlayment have higher value. When homebuyers are

choosing houses, a high - quality roof system is an important consideration. The high quality and low maintenance costs represented by

synthetic roof underlayment make houses more attractive in the market and enable them to obtain a higher selling price. A survey of

second - hand housing transactions found that houses with synthetic roof underlayment have a selling price approximately 5% - 8%

higher than those of the same type in the same area but with traditional asphalt felt roofs.

For residents, synthetic roof underlayment brings a more comfortable living experience. Its good heat insulation performance ensures

that the indoor temperature is not too high in summer and not too low in winter, reducing the frequency of using air conditioners and

heating equipment. This not only saves energy costs but also creates a pleasant living environment for residents throughout the year.

In addition, due to its excellent waterproof performance, it eliminates problems such as indoor dampness and mildew caused by roof

leakage, ensuring the health of residents.

With the continuous advancement of construction technology, roof synthetic underlayment, with its unparalleled advantages, is

bringing new concepts of cost - effectiveness and value enhancement to the construction industry. In the future, it is expected to

become the mainstream choice for roofing materials, leading the construction industry towards a more efficient, environmentally

friendly, and economic new era.

2025-01-14

DETAIL

Roof Innovation: Multi-compatible Materials Usher in a New Chapter in Architecture

In the surging wave of the current booming construction industry, the roofing engineering field has witnessed a remarkable breakthrough.

An innovative achievement has made a dazzling debut, seemingly finding an accurate solution to the compatibility problems of various

roofing materials, injecting new vitality into building roofing projects and opening a chapter of transformation.

Looking back, traditional roof waterproofing construction was fraught with difficulties. Roofing materials of different materials have vastly

different physical and chemical properties, resulting in extremely high requirements for compatible auxiliary materials. Consequently, the

construction process was complex and lengthy, like groping in a maze. This not only consumed a large amount of manpower, material

resources and time, but also led to uneven waterproofing effects, laying many hidden dangers for the overall quality and lifespan of

buildings.

However, difficulties inspired innovation. Relying on profound professional knowledge and unremitting exploration spirit, the scientific

research team conducted repeated research and experiments and finally developed a breakthrough technology. Once this technology

came out, it caused a stir in the construction industry.

Take the common asphalt shingle roof as an example. As a thermoplastic material, it is extremely sensitive to environmental temperature

changes. Seasonal alternations and day-night temperature differences can cause it to undergo obvious expansion and contraction

deformations. Nowadays, the newly developed compatible material is like a professional and tacit partner, closely adhering to the

underside of the tile base. With excellent flexibility and precise elastic modulus compatibility, it perfectly conforms to the "rhythm" of

the thermal expansion and contraction of the asphalt shingles, and seals potential gaps and pores one by one with outstanding sealing

performance, building a solid waterproof barrier for the roof, keeping the indoor space away from wind and rain, and creating a peaceful

and comfortable environment for the occupants.

When it comes to metal roofs, the innovation advantages are even more prominent. Metal materials conduct heat rapidly. In the outdoor

environment, temperature gradient changes and atmospheric corrosive media often cause them to experience thermal expansion and

contraction deformations, oxidation and rust, as well as friction damage with the base structure. The new compatible material steps

forward with stable chemical inertness and excellent buffer damping characteristics, intervening between the metal plate and the base

to effectively block external erosion, reduce heat stress conduction, and buffer friction collisions caused by displacement. Even when

strong winds, heavy rains and extreme weather strike, relying on its super adhesion and peel resistance properties, it can be firmly

connected to the metal plate to stabilize the roof structure and act as a solid backstop.

Especially in the era of diversified development of building materials, synthetic underlays have emerged in large numbers and become a

new force in roof protection. The new compatible material precisely meets its needs and shines brightly in its combination with synthetic

underlays. With unique compatibility design and optimized fitting performance, it skillfully balances the maximization of the protection

function of the synthetic underlay and its own reliable support requirements. Without affecting the normal protection process of the

synthetic underlay, it comprehensively helps it resist wind and rain, dust and sand. With super weather resistance and anti-aging

properties, it withstands long-term ultraviolet radiation, damp heat alternation and low-temperature freeze-thaw cycles, sticks to its

post, cooperates with the synthetic underlay, and escorts the long-term stable operation of the roof system, strongly promoting the

construction of high-quality roofs.

At present, this innovative achievement has successfully passed strict international and domestic quality standard tests and performed

brilliantly in several representative pilot projects. In the construction stage, professional teams highly praise its simple and efficient

installation process, which significantly shortens the construction period, reduces the difficulty of manpower allocation and minimizes

human error risks. Its waterproof sealing effect far exceeds that of traditional products, greatly reducing subsequent operation and

maintenance pressure and costs. On the end-user side, homeowners speak highly of the quality of the new roof. It has an elegant

appearance that conforms to modern aesthetics, and its durable characteristics further ensure the long-term comfort and safety

improvement of the home.

A series of remarkable achievements have attracted the attention of numerous construction enterprises, prompting them to decisively

incorporate it into their future project strategic blueprints, eager to put it into actual projects to seize the opportunity. With the market

demand growing exponentially like a snowball, the pace of its large-scale promotion and application is also accelerating.

Looking ahead, this achievement, which bears infinite innovation potential and development prospects, will surely become a leading flag

for building roofs to move towards higher quality and stronger performance, helping to create batches of architectural models that

combine aesthetic design, practical functions, stable structures and durability, taking root in the forefront of building roofing engineering

and leading the industry towards a greener, smarter and more efficient future.

2025-01-13

DETAIL

Roof Repair and New Construction Projects: Key Points of Roof Underlayment to Keep in Mind

With the continuous progress of urban construction and the renovation of old houses, the number of roof repair and new

construction projects is increasing. However, many property owners tend to overlook the roof underlayment, which actually

has a significant impact on the quality, durability of the roof, and their wallets. Here are three key points regarding roof

underlayment:

Firstly, choosing the right material is crucial.

There is a wide variety of underlayment products on the market, with a large price range. Some property owners opt for

cheap ones. While they might seem to work fine on ordinary days, when faced with extreme weather such as heavy

rainstorms or hurricanes, they are prone to cracks and damage, leading to waterproof failure, water leakage indoors, and

high repair costs. The Bigfoot roof underlayment incorporates a high-density fiber grid, which endows it with strong tensile

and tear resistance strength, providing better stability compared to traditional asphalt felts.

Secondly, precise installation is essential.

After selecting suitable underlayment materials, if the installation is careless, all previous efforts will be in vain. The

Bigfoot underlayment is designed with unique patterns that can assist workers in precise layout, ensuring correct

overlapping and avoiding water leakage through gaps. It also speeds up the installation process and improves

accuracy, guaranteeing quality while saving time.

Finally, regular maintenance and inspection for potential hazards is the

"secret to longevity".

Roofs are constantly exposed to the elements like sun, wind, and rain, causing significant wear and tear on the underlayment.

Regular inspection is the "secret to longevity". Property owners need to arrange professional personnel to regularly check the

underlayment for signs such as blistering, peeling, loosening, or curling, and repair any issues in a timely manner to prevent

large-scale damage that would result in high repair costs.

Reminder to property owners: whether you are repairing or constructing a new roof, do not underestimate the importance

of underlayment. Keep these three points in mind to lay a solid foundation for your roof. We will also share more practical

information about construction projects later.

2025-01-13

DETAIL

Safeguarding the Roof Defense Line: The Stability of Synthetic Liners Becomes the Key

In the current booming construction industry, the roof, as the crucial defense line to protect buildings from wind and rain, demands

stricter quality control. And the roof synthetic liner, as the "unsung hero" in this defense line, its thermal stability and dimensional

stability are becoming the focus of the industry and triggering extensive discussions.

In the current booming construction industry, the roof, as the crucial defense line to protect buildings from wind and rain, demands

stricter quality control. And the roof synthetic liner, as the "unsung hero" in this defense line, its thermal stability and dimensional

stability are becoming the focus of the industry and triggering extensive discussions.

Recently, the results of a research on building materials are alarming. Many old buildings have problems such as roof leakage and

insulation failure. Tracing back to the source, it is mostly related to the poor stability of the roof synthetic liner. Under the scorching

sun in summer, some traditional liner materials, due to insufficient thermal stability, show signs of softening and flowing, resulting in

the rupture of the waterproof layer and allowing rainwater to seep in. In the cold winter months, the low temperature makes some

liners fragile and brittle. With slight external forces, such as snow accumulation and strong wind pulling, the liners crack, causing a

large amount of indoor warmth to be lost.

Thermal stability, simply put, is the ability of the liner to maintain its own performance in a high-low temperature alternating environment.

When the temperature soars, high-quality synthetic liners, relying on their special molecular structures and heat-resistant additives, can

hold their ground without deformation or aging, ensuring the integrity of the waterproof coating and the stability of the insulating air

layer. Conversely, if the thermal stability fails to meet the standard, the roof may instantly turn into a "steaming oven", with the scalding

hot air directly hitting the interior, making residents miserable; or when it rains heavily, the house may quickly become a "water curtain

cave", causing property damage.

Dimensional stability is equally important. Buildings will experience settlement, expansion, and contraction due to the passage of time

and climate change, and the roof is no exception. At this time, a dimensionally stable liner is like a flexible and loyal guard, closely

adhering to the roof surface, expanding and contracting with it, and seamlessly adapting to every subtle change. In contrast, for those

liners with poor dimensional stability, when there is the slightest movement on the roof, they will stretch and retract on their own, and

the seams will "open wide", allowing rainwater to rush in, eroding the building structure and greatly shortening the lifespan of the house.

Fortunately, researchers and enterprises have made significant progress in improving the stability of roof synthetic liners. From the

perspective of material innovation, new high-molecular composite materials have emerged. They are formed by combining multiple

high-temperature-resistant and tensile-resistant monomer components through complex processes, and their thermal stability and

dimensional stability far exceed those of traditional products. In terms of production technology, precise temperature-controlled

injection molding and multi-layer co-extrusion compounding technologies make the internal structure of the liner compact and orderly,

greatly enhancing the overall stability.

Nowadays, more and more builders put the stability of liners first when selecting materials and require suppliers to provide long-term

test data under simulated extreme environments to ensure everything is foolproof.

Looking ahead, although there are still challenges on the way forward, such as reducing the cost of high-performance liners and

accelerating the research and development of environmentally friendly products, with the continuous upgrading of technology,

roof synthetic liners will surely provide a solid "protective umbrella" for each building with more excellent thermal stability and

dimensional stability, safeguarding the warm lives of thousands of households.

2025-01-11

DETAIL

Guide to Roof Inspection for Second-hand Houses: Synthetic Underlayment Becomes a Wise Choice

In the current active real estate trading market environment, many homebuyers have set their sights on second-hand

housing resources. However, an easily overlooked yet crucial question arises: after buying a second-hand house, should

the roof be inspected? The answer is unquestionable — it must be inspected!

Many homebuyers take chances and are reluctant to bear additional maintenance costs too early. But once they move

in, the real challenges come one after another. The length of time the previous owner lived in the second-hand house is

unknown, and it's even more impossible to know when the roof was last repaired. A roof that hasn't been properly

maintained for a long time is like a "time bomb" that could trigger a series of problems at any time.

“The gaps in the old roof cause losses indoors during the rainy season"

Whenever the rainy season arrives, it's time for the old roof to "reveal its true colors". Rainwater seems to find a shortcut

to invade the house, seeping in through the gaps in the roof. Precious calligraphy and paintings, as well as knowledge-

bearing books, quickly become moldy and deteriorate under the attack of moisture, losing their original value; wooden

floors can't bear the weight of accumulated water and gradually deform and warp, not only affecting the appearance but

also posing a potential safety hazard; electronic devices short-circuit and get damaged in the "close encounter" with rainwater,

incurring high repair costs. Once these household properties are damaged, the economic losses are immeasurable, and

family life is thrown into chaos.

“From high initial purchase cost to long-term super returns”

Facing this dilemma, how can we find a permanent solution for the roofs of second-hand houses? Bigfoot synthetic

underlayment stands out and becomes the best choice. Although its cost is slightly higher than that of traditional

asphalt felt in the initial procurement stage, its advantages are obvious when looking at the long-term usage benefits.

The synthetic roof underlayment, with its outstanding durability, can withstand the test of time and stand firm year

after year; it greatly reduces the trouble of frequent maintenance, allowing homeowners to bid farewell to the troubles

of periodic roof inspections; most importantly, it minimizes the risks of leakage and damage. This means that in the

long run, homeowners can not only save on the high costs caused by repeated roof repairs but also avoid compensation

for property damage inside the house due to water infiltration, truly saving a large amount of money and safeguarding

family assets.

Nowadays, more and more second-hand homeowners have realized the importance of roof inspection and upgrading,

and they have chosen Bigfoot synthetic underlayment one after another to start a new chapter of worry-free home life.

Experts suggest that after the completion of a second-hand house transaction, homeowners should never neglect the

condition of the roof and should promptly choose high-quality synthetic underlayment to build a solid defense line for

their homes so that they can enjoy a comfortable living experience.

2025-01-11

DETAIL

Synthetic Liner Industry: Standard Innovation Leads the New Development Journey

In the current booming construction field, synthetic liners, as crucial materials for roof protection, are facing profound changes

in industry standards and regulations.

Enhancement of Performance Standards:

Recently, with the rapid progress of construction technology and the almost stringent requirements for building quality,

the performance standards of synthetic liners have entered a track of rapid renewal and improvement. Waterproof

performance is regarded as the "basic skill" of synthetic liners. In terms of weather resistance, by adding special antioxidants

and ultraviolet stabilizers, it is ensured that the liners will not fade, crack or deform under the cycle of seasons with scorching

sun exposure, cold wind blowing and acid rain erosion, protecting the roof for decades. The puncture resistance is even

more crucial for safety. New fiber reinforcement technologies have been introduced. Whether it is accidental falling tools

during construction or occasional external impacts on the roof in the future, it is difficult for them to penetrate the liners,

providing a solid shield for the interior of the building. The fireproof performance cannot be underestimated either. The

innovative formula with flame retardants allows synthetic liners to effectively slow down the spread of fire when facing fire

hazards, buying precious time for personnel evacuation and fire rescue.

Internationalization of Standards:

At the same time, against the backdrop of the surging wave of globalization, the internationalization of standards has

become another significant trend in the synthetic liner industry. International trade exchanges are becoming more and

more frequent, and industry standards of various countries are accelerating their convergence and integration. On the

one hand, domestic enterprises are actively participating in the formulation and promotion of international standards.

When some countries raise environmental protection index requirements, Bigfoot adjusts its raw material procurement

and production processes, adopts more environmentally friendly degradable materials to ensure product compliance

and gain a firm foothold in international competition.

It can be foreseen that driven by the dual wheels of industry standards and regulations, the synthetic liner industry will

sail smoothly on the road of innovative development, injecting a continuous stream of impetus into the improvement

of global building quality.

2025-01-10

DETAIL

Hidden Strength, Guarding High-altitude Safety

In the current period of continuous innovation in the construction sector, a quietly emerging material is silently rewriting the chapter of

roof construction and maintenance. It is the roof synthetic liner. Although not widely known to the public, its outstanding features,

especially its remarkable anti-slip property, have already become the unsung hero safeguarding high-altitude operation safety.

With the growing diversity of modern architectural styles, a large number of steep-slope roofs and special-shaped roofs that pursue

unique visual effects have emerged. While these undoubtedly add distinctive charm to the city skyline, they bring numerous potential

risks to construction workers who are busy moving about on the roofs and those responsible for subsequent maintenance. Traditional

roof liner materials generally have a smooth surface. Once wetted by rain, dew, or covered with a thin layer of dust, their surfaces

become slippery and the frictional force drops drastically. Just imagine, when workers are working on a high-altitude roof, it feels as if

they are standing on a perilous “skating rink”. Any slight misstep can easily lead to slips and injuries. If they are at a higher floor or in a

complex roof structure area, a chain reaction triggered by a single slip is likely to result in a serious fall accident, posing a great threat to

their lives.

Just when this thorny issue urgently needed to be resolved, the roof synthetic liner emerged like a ray of dawn breaking through the night

sky. It embodies the wisdom of cutting-edge material technology and has maximized the anti-slip performance. Its surface features not

ordinary textures, but fine and interlaced micro-protrusions and grooves meticulously designed and optimized by researchers, much like

the natural anti-slip “secret paths” crafted by nature. In a clear sky and dry, pleasant environment, these textures seem to come alive, like

countless invisible hands firmly gripping the soles of shoes, providing solid support for each step of the workers, enabling them to walk

on the roof as easily and confidently as on flat ground. Even when the weather changes abruptly and it rains heavily, causing water to pool

on the roof, the synthetic liner remains unfazed. The rainwater will swiftly drain away along the carefully designed grooves between the

textures, cleverly preventing the formation of large, bothersome water films on the surface. And those protrusions stand firm above the

water surface like pillars, always staying in close contact with the soles of shoes, ensuring that the friction between the soles and the liner

is not easily diminished by the rain. Even during daily operations when dust accumulates gradually, those fine dust particles, facing the

“maze” of grooved textures, can only look on helplessly, unable to fill them up, and the good frictional effect between the soles and the

liner persists. Whether workers are climbing a nearly vertical steep roof, leaning forward and concentrating, or in a critical moment when

the wind is howling and their center of gravity is unstable, relying on the powerful anti-slip guarantee of the roof synthetic liner, they can

stand firm, greatly enhancing the safety factor of high-altitude operations and adding a sense of security to every rooftop adventure.

Not only does it possess excellent anti-slip capabilities, but the roof synthetic liner also performs exceptionally well in terms of durability.

After long-term exposure to the merciless bombardment of ultraviolet rays, it will not, like ordinary materials, suffer from texture wear and

surface degradation that would lead to a significant reduction in anti-slip function. Behind this is the silent contribution of its stable and

elaborate high-molecular structure, which is like an impregnable fortress built for the surface textures, firmly locking every tiny protrusion

and groove. The ultraviolet rays in sunlight, like sharp “light swords”, can easily sever the chemical bonds of many conventional materials

and cause their molecular structures to collapse. However, the roof synthetic liner, by virtue of its unique molecular arrangement “shield”,

skillfully resists the invasion of ultraviolet rays, ensuring that the surface textures remain intact for years or even decades, always paving a

reliable anti-slip path for everyone who steps on the roof.

From the perspective of installation convenience, the roof synthetic liner offers even more advantages. It is as light as a gossamer, yet

harbors tenacious strength and has excellent flexibility. It can, like a nimble dancer, effortlessly conform to various complex and strange

roof contours. Construction workers only need simple tools to complete the laying work quickly and accurately, substantially shortening

the construction period and reducing the input of manpower and material resources. This is undoubtedly a timely boon for the

time-sensitive construction process.

In today’s era when the concept of environmental protection has deeply penetrated people’s minds, many roof synthetic liner products

closely follow the trend of the times and are carefully manufactured using recyclable environmental protection materials, minimizing the

negative impact on the ecological environment and perfectly aligning with the booming trend of green building.

Currently, although the roof synthetic liner is still in the ascending stage of market promotion, it has already made a mark in some newly

built high-end residential communities, extremely innovative commercial complexes, and large-scale industrial plants such as Oriental

Yuhong. It has won unanimous acclaim from architects, construction teams, and owners. Looking ahead, with the continuous improvement

of manufacturing technology and the steady control of production costs, it is expected that in the next few years, the roof synthetic liner will,

by virtue of its outstanding anti-slip performance, excellent durability, and convenient construction characteristics, spread like wildfire in

various construction projects, reshaping the safety paradigm of roof construction and maintenance and creating a more secure and

comfortable environment for people.

Admittedly, just as the growth path of all new things is frailed with thorns, the development of the roof synthetic liner also faces hurdles.

On the one hand, the market has a shallow understanding of its outstanding anti-slip advantages, and many potential customers, shackled

by traditional thinking, still tend to choose familiar traditional liners. On the other hand, the high initial R & D investment has led to a

relatively high initial price of the product, which, to some extent, restricts its market expansion pace. However, industry insiders generally

have an optimistic view of its development prospects. They believe that with the in-depth implementation of publicity and promotion and

the cost optimization brought about by large-scale production, these temporary obstacles will eventually be overcome.

In conclusion, the roof synthetic liner, by virtue of its outstanding anti-slip performance, excellent durability, convenient construction

advantages, environmental protection production concept, and broad development prospects, has already become a pillar in the field

of building safety and is expected to shine brightly in the near future, opening a new chapter in roof safety protection.

2025-01-10

DETAIL

Roofing Materials Innovation: Propelling the Construction Industry Towards a New Journey

In today's era of rapid development, the construction industry is undergoing a profound transformation spurred by innovations in roofing

materials.

Recently, a series of new roofing materials have emerged in quick succession, becoming the focus of attention in the industry. These

innovative achievements have first brought remarkable benefits in terms of energy utilization and cost control. There is a new type of

heat-insulating roofing material. Its breakthrough heat-insulation design makes buildings seem to be guarded by an efficient

heat-insulating barrier in summer. According to actual monitoring data, the indoor temperature of ordinary residences equipped with

this type of material is, on average, 5 to 8 degrees Celsius lower than that of residences using traditional roofing materials. This directly

leads to a significant reduction in the usage time of air conditioners and a sharp decrease in residents' electricity bills. For large buildings

such as commercial complexes and office buildings, the energy-saving effect is even more astonishing. It not only alleviates the urban

power shortage but also enables operators to save up to 30% of their energy consumption costs, greatly enhancing the overall

profitability of the projects and attracting the attention of developers and property owners.

In terms of enhancing building quality, innovative roofing materials also play a crucial role. The new waterproof materials utilize

cutting-edge technologies to form a tightly arranged protective layer at the microscopic level, completely resolving the long-standing

problem of roof leakage. In the past, due to long-term erosion by rainwater and ultraviolet radiation, traditional materials often required

maintenance or even replacement of the roof surface within a few years. Nowadays, buildings using this type of new waterproof roofing

material can extend their waterproof lifespan to more than 20 years. This effectively avoids the risk of building structure damage caused

by roof problems, ensures the long-term stability of the building, reduces the waste of manpower, material resources, and environmental

pollution caused by frequent renovations, and lays a solid foundation for the sustainable existence of the building.

The environmental protection field is a key focus of roofing material innovation. Many material manufacturers are actively exploring ways

to utilize recyclable resources. For some new roofing materials, most of their raw materials are sourced from recycled plastics, waste

metals, etc., and the energy consumption during the production process is 40% lower than that of traditional materials. In this way, it not

only reduces the dependence on non-renewable resources such as original minerals but also reduces carbon emissions in the production

process. This transformation helps buildings easily meet international green building standards. Many new construction projects, by virtue

of the advantages of environmentally friendly roofing materials, have seen a significant improvement in their green star ratings and have

seized the initiative in market bidding, prompting the entire construction industry chain, from upstream raw material supply to downstream

construction, to accelerate the transformation towards green environmental protection.

From the perspective of architectural design and application expansion, innovative roofing materials have broken the "constraints" of

design. Previously, to ensure drainage and heat dissipation, most building roofs adopted conventional sloping shapes. Nowadays, new

materials with super heat-insulation and waterproof capabilities have enabled the vigorous development of flat roofs and special-shaped

roofs. Some pioneering architects have designed visually striking works such as "floating roofs" and "honeycomb roofs" using new

materials, reshaping the city skyline. Meanwhile, significant breakthroughs have also been made in special application scenarios. In

precision instrument laboratories, the accuracy of experimental data has been significantly improved due to the new materials' ability

to precisely control temperature and humidity; precious cultural relics in cultural relics protection venues can also be better preserved

thanks to the stable indoor environment. These new demands further expand the business territory of the construction industry and

spawn a large number of emerging projects.

It can be foreseen that with the continuous upsurge of the innovation wave of roofing materials, the construction industry will surely ride this

strong "east wind" and move forward at full speed towards a more green, efficient, and diversified direction, creating higher-quality, smarter,

and more environmentally friendly living and workspaces for people and opening a new chapter of development.

2025-01-09

DETAIL

Synthetic Liners Escort Roof Protection

In the field of building maintenance, roof protection has always been a key concern. Recently, with the development of

construction technology, the important role of roof underlayment in various roof protections has sparked heated discussions.

Many modern buildings adopt advanced splicing techniques and new materials to build roofs, with each panel closely

connected. At first glance, these well-sealed roofs seem impregnable, with seamless joints, as if they were equipped with

an "invisible armor" to resist external invasions, and theoretically, they can keep out moisture and dust.

Roof hidden dangers under the impact of reality

However, reality is far more complex than imagination. The power of nature cannot be underestimated. The violent impact

of summer rainstorms, the biting cold of winter winds, and the frequent alternation of wet and dry in spring and autumn

all put the roof in a "high-pressure" environment for a long time. Even for roofs with initially firm splicing, after being exposed

to climatic tests for a long time, slight loosening will gradually appear, laying hidden dangers for leakage problems.

The Highlight Moment of Synthetic Liners

At this time, the advantages of roof synthetic liners are fully demonstrated. Taking the much-talked-about "bigfoot" liner

as an example, it stands out with its excellent waterproof and moisture-proof performance as well as excellent flexibility.

It can closely adhere to the underside of the roof, building a solid "second line of defense" at potential leakage points.

When the rain pours down, the liner reacts rapidly, effectively dispersing the impact force of the water flow and nipping

the risk of water infiltration in the bud.

The Long-Term Consideration from Experts' Perspective

An expert from a certain building maintenance company pointed out: "Although the initial installation of roof liners will

increase certain costs and procedures, considering the long-term benefits, it is of great significance for prolonging the

service life of the roof and reducing subsequent frequent maintenance. It is a wise choice to ensure the long-term protection

of the roof in the future." In the renovation projects of old roofs, there have been many successful cases. For example, after

the introduction of liner protection in [a certain old community name], residents bid farewell to the problem of indoor water

leakage during the rainy season, and their quality of life has been significantly improved.

With the promotion and application of technology, more and more construction practitioners and property owners have

recognized the value of roof liners. It is gradually becoming an indispensable key element for roof protection, injecting

strong impetus into the durability of buildings, and opening a new chapter in building protection.

2025-01-09

DETAIL

Powerful “Backing”: New Synthetic Liners Drive Industrial Advancement

Recently, a remarkable breakthrough has been achieved in the field of materials science. A novel synthetic liner, possessing outstanding

durability and remarkable anti-aging capabilities, has made a splashy debut. It resembles a key that unlocks the gateway to new

development, injecting vigorous impetus into numerous industries mired in difficulties and forcefully propelling them towards a higher

echelon.

In the crucial realm of industrial manufacturing, traditional liners have long been an impediment to efficient production. Under the severe

operating conditions of high-speed and high-intensity machinery, their frail nature becomes glaringly evident. Frequent frictional wear and

tear, along with aging deterioration under continuous stress, lead to frequent equipment breakdowns. Machinery shutdowns for

maintenance have become a persistent headache for enterprises, accompanied by hefty repair costs and substantial losses due to

production delays. In stark contrast, the new synthetic liner is akin to a magnum opus embodying the quintessence of cutting-edge

research. The R & D team adeptly employed advanced molecular engineering techniques to meticulously engineer the microscopic

molecular architecture, cleverly integrating novel polymeric materials with exceptional mechanical properties, endowing the liner with

incredible strength and toughness. After a series of rigorous and professional industrial standard tests, its wear resistance performance

has witnessed a quantum leap compared to traditional counterparts, exhibiting extraordinary durability and laying a solid foundation for

the stable and continuous operation of the modern industrial production system, truly qualifying as an invaluable “ally” for enterprises

seeking to optimize benefits and cut costs.

When shifting our focus to the expansive domain of outdoor infrastructure construction, synthetic liners bravely confront the myriad

challenges posed by nature. In the outdoor milieu, continuous ultraviolet bombardment, drastic temperature fluctuations, repeated

rainwater scouring, and chemical corrosion from atmospheric pollutants all conspire to assail the service life of liner materials. However,

armed with profound academic acumen and an unwavering spirit of exploration, researchers have precisely tackled these issues. They

harnessed the industry-leading additive compounding technology to artfully combine and meticulously optimize multiple additives with

superlative anti-aging and excellent weather resistance attributes, tailoring an impregnable protective regime for synthetic liners. In

long-term accelerated aging trials simulating complex outdoor environments, this synthetic liner calmly withstood prolonged and intense

challenges. Its core functions remained rock-solid, and key performances such as waterproofing, heat insulation, and cushioning stayed

consistently reliable, furnishing a robust guarantee for the long-term viability of infrastructure projects like roads, bridges, and building

facades, and powerfully facilitating urban construction to ascend to a higher quality and more resilient tier.

It is especially noteworthy that from its very inception, this synthetic liner has deeply embedded the concept of green development.

During the raw material selection phase, it strictly adheres to environmentally friendly criteria, giving precedence to renewable and

low-impact base materials. In the design and implementation of the production process, clean production technologies have been

comprehensively incorporated to minimize energy consumption and waste emissions, ensuring that the perturbation to the ecological

environment throughout its lifecycle is kept to a minimum. Thanks to its exceptionally long service life, it effectively curtails resource

waste and environmental burdens stemming from frequent material replacements, truly realizing the harmonious coexistence of industrial

development and ecological preservation, in perfect harmony with the global sustainable development trend.

Looking ahead to the panorama of future industrial development, as this state-of-the-art technology progressively gains ground, a

multitude of sectors such as transportation, energy storage, electronic information, and agricultural production will reap profound benefits

from the sterling qualities of synthetic liners. In the rail transit arena, the safeguarding of critical components and the operational stability

of high-speed conveyances like subways and high-speed trains will be markedly enhanced with the aid of synthetic liners. In the energy

strategic reserve domain, the safety, reliability, and durability of large storage facilities such as oil tanks and gas storage tanks will scale

new heights by relying on it. In the electronic device manufacturing field, the precision protection and heat dissipation architectures within

sophisticated products like smartphones and laptops will be optimized and upgraded courtesy of synthetic liners. Focusing on the

agricultural modernization drive, the efficient operation and long-term upkeep of irrigation systems will also be assured through leveraging

it. Industry pundits confidently prognosticate that in the near future, this synthetic liner will undoubtedly distinguish itself in the liner material

market with its incontestable technical prowess and outstanding performance, remolding the collaborative ecosystem of the upstream and

downstream of the industrial chain and emerging as the prime mover for global industries to stride towards high-quality development. At

present, forward-looking enterprises with acute business acumen have already sprung into action, hastening to expand production capacity

and upgrade technologies, vying to seize the initiative in this impending global industrial transformation tempest and bring this innovative

technological feat to the benefit of society at large as soon as possible, thereby inaugurating a new chapter in human production and life.

2025-01-08

DETAIL

Industry Focus: Unveiling the Greatest Misconception about Roof Synthetic Underlayment

In the current booming construction industry, roof synthetic underlayment, serving as a crucial material safeguarding key properties

like waterproofing and wind resistance for houses, is entangled in numerous misunderstandings. Recently, journalists have carried

out in-depth visits to building materials experts, construction teams, and a vast number of actual project sites to probe into what

exactly the biggest misconception about roof synthetic underlayment is.

After extensive investigations, it has been discovered that the most prevalent misconception in the market currently is that “the

thicker it is, the more durable it will be”. Many homeowners and even some small construction crews often judge the product

quality merely based on the intuitive thickness when choosing roof synthetic underlayment. They presume that the thicker the

underlayment, the better it can withstand wind and rain erosion and the longer its service life will be. However, this is far from

the truth.

A building materials expert pointed out: “The durability of synthetic underlayment is not determined solely by its thickness. The

molecular structure of the material, the waterproof and breathable performance indicators, as well as the application of anti-aging

additives are the decisive factors.” Some inferior thick underlayments on the market simply add filling materials to increase the

thickness, but in fact, they have serious deficiencies in core aspects such as waterproofness and flexibility. Once confronted with

heavy rain and water accumulation, these “puffed-up” thick underlayments are highly prone to leakage, and due to insufficient

flexibility when the temperature changes, they are liable to crack and break, shortening the lifespan of the roof instead.

At the renovation construction site of an old building, the person in charge, Oscar, also reported to the journalist: “In some

renovation projects I took over before, the original roofs were equipped with thick underlayments, but problems emerged frequently

just a few years later. After careful inspection, it was found that the internal fiber structure of the underlayment was loose and the

waterproof coating was of poor quality, completely unable to endure daily wind and rain. In contrast, some synthetic underlayments

produced in accordance with formal standards and with a moderate thickness, relying on advanced polymer formulations, have

remained intact for over ten years on multiple buildings.”

The widespread existence of this misconception not only causes consumers to waste money on inappropriate products but also

poses significant hidden risks for subsequent house maintenance. so that roof synthetic underlayment can truly fulfill its due

protective functions and provide a solid “protective umbrella” for each building. In the future, with the gradual elimination of

cognitive misunderstandings, the roof synthetic underlayment industry is expected to move towards a more standardized and

efficient development stage.

2025-01-08

DETAIL

New Synthetic Roof Underlayment: Compatible with Diverse Roofing Materials, Enhancing Roof Durability

Recently, a major breakthrough has emerged in the field of building materials - the widespread application of synthetic roof

underlayment has attracted significant attention. Research and practice have shown that this synthetic roof underlayment

exhibits outstanding compatibility with a variety of roofing materials, providing a brand-new solution for the stability and

durability of building roofs.

In terms of multifunctional roofing applications, the synthetic roof underlayment can be regarded as a "universal adapter".

Whether it is common asphalt shingles, various metal sheets such as those made of steel, aluminum, copper, or traditional

clay tiles, concrete tiles, and even wood shingles and composite panels, it can achieve perfect compatibility. Its specially

treated surface neither interferes with the adhesion of roofing materials, ensuring that tiles and sheets can be firmly attached

to the roof under different climatic conditions, nor has a negative impact on the thermal expansion of materials, enabling

the roofing system to remain stable when the temperature changes. This compatibility has greatly expanded the material

selection range for architects and builders, making roofing design more diversified.

Moreover, the synthetic roof underlayment plays an indispensable role in extending the service life of the roof covering

layer. It creates a dry and stable base for the upper roofing materials, just like putting on a "protective coat" for the roof.

Taking a metal roof as an example, after laying the synthetic roof underlayment underneath, it can effectively suppress

the corrosion caused by water vapor erosion at the bottom, significantly prolonging the service life of the metal roof;

under an asphalt shingle roof, the underlayment reduces the risk of asphalt compound leakage caused by overheating

in summer, keeping the asphalt shingles in good condition and avoiding frequent repairs and replacements.

The emergence of synthetic roof underlayment is expected to achieve large-scale popularization in the future, propelling

the construction industry towards a higher-quality development stage and creating more solid and durable roof protection

barriers for numerous buildings.

It is believed that with the continuous advancement of technology, the synthetic roof underlayment will continue to optimize

its performance, providing more long-term and reliable roofing protection for various buildings. Let's wait and see it shine

even more brightly in the construction field.

2025-01-07

DETAIL

BIGFOOT 15

Learn More

BIGFOOT 15

Learn More

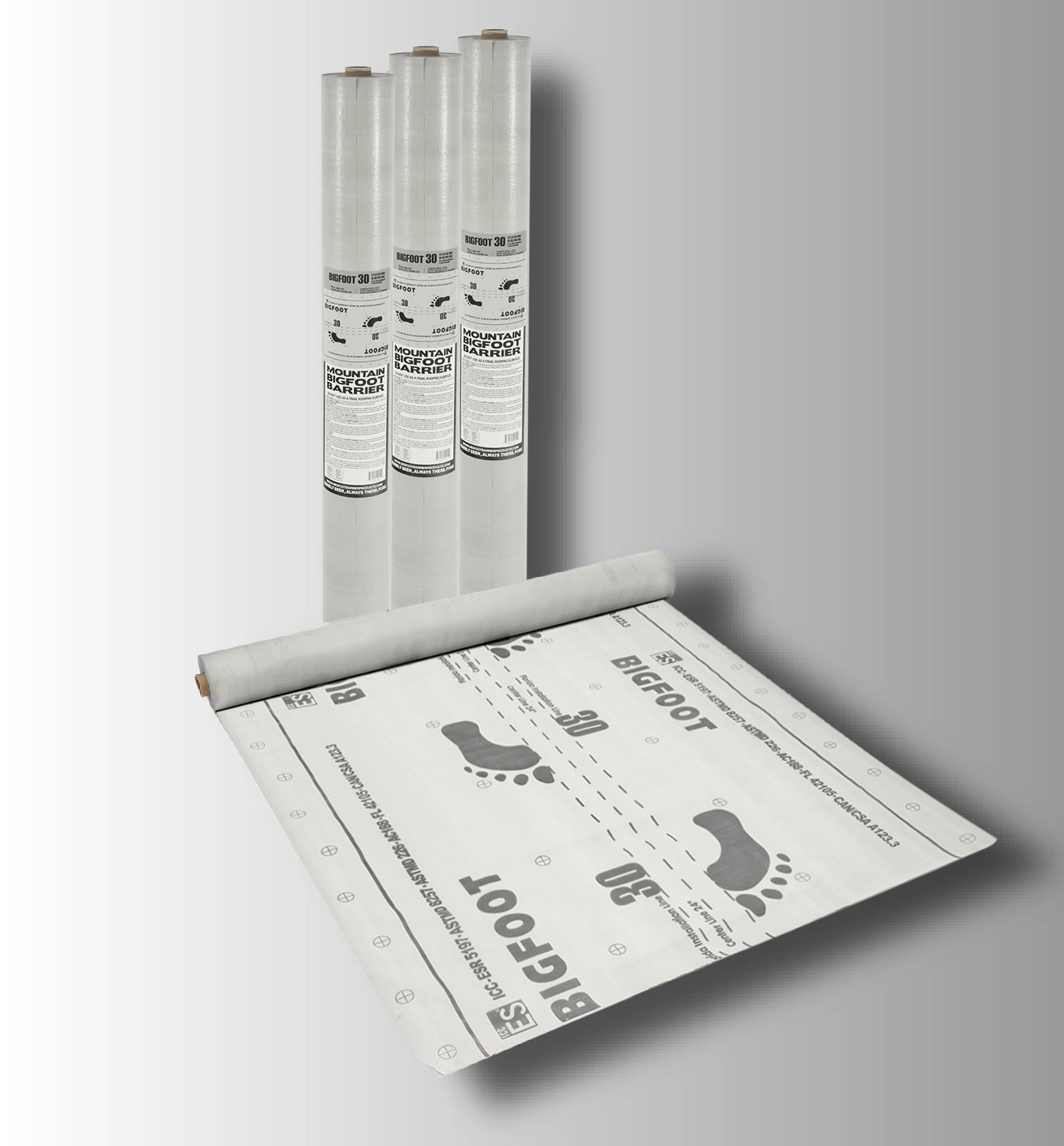

BIGFOOT 30

Learn More

BIGFOOT 30

Learn More

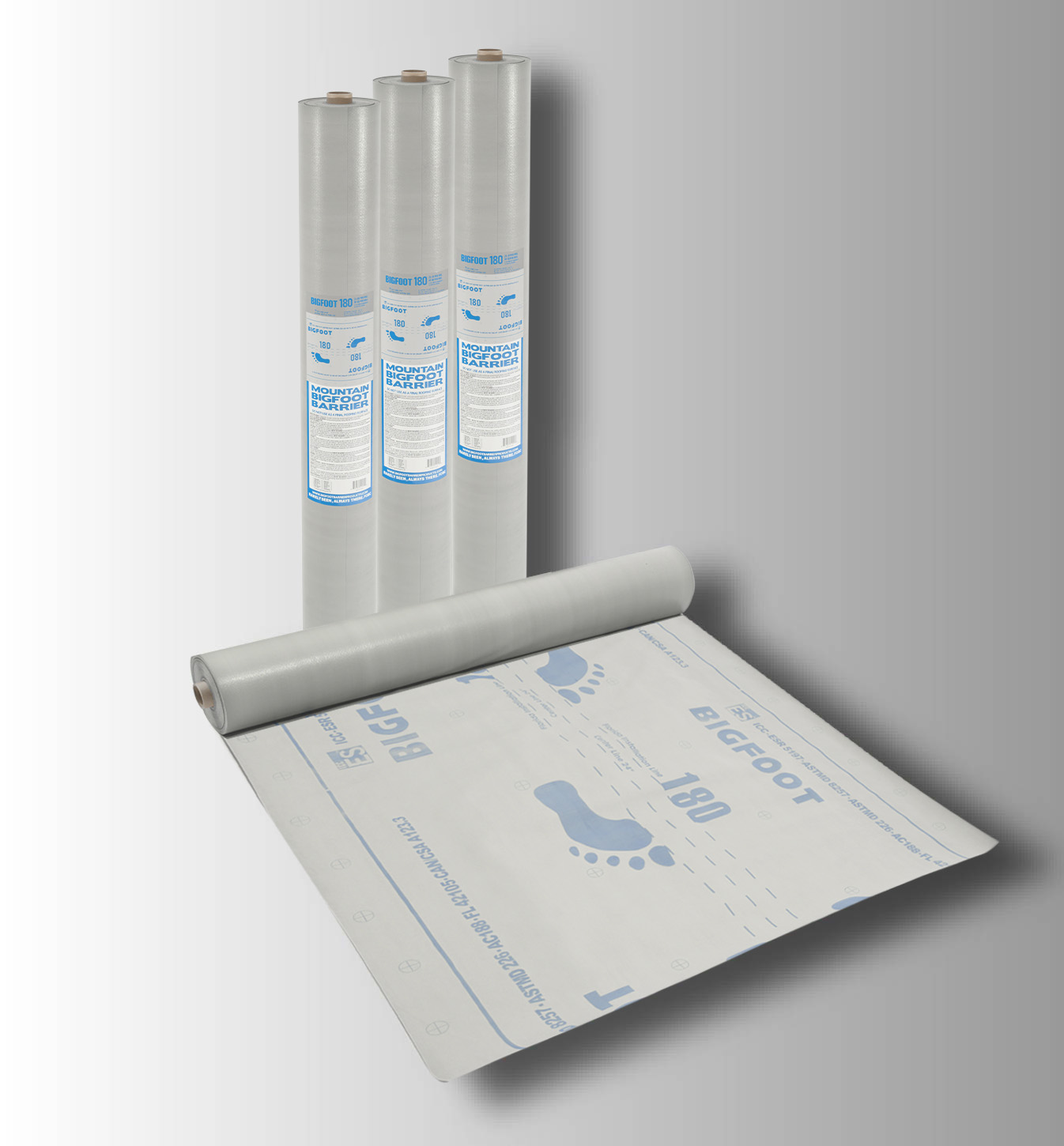

BIGFOOT 180

Learn More

BIGFOOT 180

Learn More

BIGFOOT HD

Learn More

BIGFOOT HD

Learn More

BIGFOOT 15

BIGFOOT 15

BIGFOOT 30

BIGFOOT 30

BIGFOOT 180

BIGFOOT 180

BIGFOOT HD

BIGFOOT HD

Back

Back