Environmental Adaptability and Long-Term Performance of Synthetic Roof Underlayment

Synthetic roof underlayment plays a crucial role in modern roofing systems, widely used in various construction projects. Compared to traditional roofing materials, synthetic roof underlayment offers excellent weather resistance, UV protection, thermal insulation, and waterproofing capabilities. It performs well in various climates and environments. However, different environmental conditions can impact the performance and lifespan of synthetic underlayment. Understanding these factors is essential for selecting and maintaining synthetic roof underlayment. This article explores the environmental adaptability and long-term performance of synthetic roof underlayment.

1. Environmental Adaptability

The adaptability of synthetic roof underlayment is primarily reflected in its performance in various climatic conditions, including high temperatures, low temperatures, humidity, and exposure to wind and sand. Depending on these factors, synthetic underlayment provides long-lasting protection for buildings.

1.1 High Temperature and Tropical Climate Adaptability

In hot or tropical regions, roofs face intense sunlight and significant temperature fluctuations. Synthetic roof underlayment materials are designed to withstand high temperatures, maintaining their stability and performance over time. Materials such as TPO and EPDM are heat-resistant, ensuring that they do not degrade or deform under prolonged sun exposure.

Additionally, high temperatures and intense UV radiation typically cause traditional roofing materials to age or become brittle. Synthetic roof underlayment, however, is engineered with UV-resistant components, which help reduce this effect, maintaining flexibility and durability. In tropical or subtropical climates, synthetic underlayment prevents premature aging of the roof, extending its lifespan.

1.2 Low Temperature and Cold Climate Adaptability

In cold climates, especially where temperatures fall below freezing, roofing materials face challenges such as cracking, shrinkage, and thermal expansion. Synthetic roof underlayment, particularly EPDM, remains flexible and strong even in extremely low temperatures, preventing cracking and deformation caused by temperature fluctuations.

Moreover, synthetic underlayment provides excellent thermal insulation, reducing heat loss and helping maintain stable internal temperatures during cold weather. This insulation capability also contributes to energy savings by reducing the need for heating.

1.3 Humidity and Damp Climate Adaptability

In humid or coastal regions, roofs are exposed to higher moisture levels, increasing the risk of mold and algae growth. Synthetic roof underlayment offers strong waterproofing and moisture resistance, effectively preventing water from infiltrating the roof structure.

Unlike traditional roofing materials, which may absorb moisture, synthetic underlayment does not allow water penetration, which helps preserve the structural integrity of the roof. In addition, many synthetic underlayments have anti-microbial properties that prevent the growth of mold and algae, maintaining the roof’s cleanliness and functionality in wet environments.

1.4 Wind and Sand Exposure Adaptability

In regions where wind and sand are prevalent, such as deserts or coastal areas, dust and sand particles can accumulate on the roof, leading to wear and contamination of the roofing materials. Synthetic roof underlayment is designed to be more resistant to abrasion and pollution than traditional materials. Its smooth surface reduces the attachment of dust and debris, making it easier to clean and maintain.

Furthermore, synthetic underlayment is highly resistant to strong winds and does not easily degrade from wind-blown sand. Its stability and durability in such environments ensure that it continues to provide reliable protection for the roof.

2. Long-Term Performance

The long-term performance of synthetic roof underlayment is mainly reflected in its durability, resistance to aging, waterproofing capacity, and maintenance requirements. Over time, synthetic underlayment may undergo natural aging, but it has been designed to withstand extended use, ensuring continued protection for the roof.

1.1 High Temperature and Tropical Climate Adaptability

In hot or tropical regions, roofs face intense sunlight and significant temperature fluctuations. Synthetic roof underlayment materials are designed to withstand high temperatures, maintaining their stability and performance over time. Materials such as TPO and EPDM are heat-resistant, ensuring that they do not degrade or deform under prolonged sun exposure.

Additionally, high temperatures and intense UV radiation typically cause traditional roofing materials to age or become brittle. Synthetic roof underlayment, however, is engineered with UV-resistant components, which help reduce this effect, maintaining flexibility and durability. In tropical or subtropical climates, synthetic underlayment prevents premature aging of the roof, extending its lifespan.

1.2 Low Temperature and Cold Climate Adaptability

In cold climates, especially where temperatures fall below freezing, roofing materials face challenges such as cracking, shrinkage, and thermal expansion. Synthetic roof underlayment, particularly EPDM, remains flexible and strong even in extremely low temperatures, preventing cracking and deformation caused by temperature fluctuations.

Moreover, synthetic underlayment provides excellent thermal insulation, reducing heat loss and helping maintain stable internal temperatures during cold weather. This insulation capability also contributes to energy savings by reducing the need for heating.

2.3 Anti-Biological Resistance

Synthetic roof underlayment’s smooth surface and water-resistant structure effectively prevent the growth of biological contaminants like mold, algae, and mildew. This feature is especially important in humid and damp climates, where traditional roofing materials may be more susceptible to biological growth.

The anti-microbial properties of synthetic materials help maintain the roof’s cleanliness and functionality, preventing the biological degradation of roofing systems. This resistance to biological contamination ensures that the roof remains both effective and aesthetically pleasing over time.

2.4 Low Maintenance and Long Lifespan

Synthetic roof underlayment is known for its durability, meaning that once it is installed, it requires relatively little maintenance. Compared to traditional roofing materials, which may need regular inspections, repairs, or replacements, synthetic underlayment offers lower maintenance costs.

Routine maintenance generally involves cleaning the roof surface, inspecting seams and drainage systems, and checking for potential damage. With proper care, synthetic roof underlayment can continue to perform well for decades, reducing long-term costs and increasing the overall lifespan of the roof.

3. Conclusion

Synthetic roof underlayment demonstrates exceptional environmental adaptability and long-term performance in a variety of climates. Whether exposed to high temperatures, freezing conditions, high humidity, or wind and sand, synthetic underlayment provides continuous protection for buildings. As technology advances, the performance of synthetic roof underlayment will continue to improve, further broadening its application in the construction industry. With proper material selection, design, and maintenance, synthetic roof underlayment offers reliable, environmentally friendly, and efficient roofing solutions for the future.

2025-04-22

DETAIL

Synthetic Roofing Underlayment Demonstrates Significant Economic Advantages, Long-Term Cost-Effectiveness Gains Attention

In the field of building materials, synthetic roofing underlayment has gradually become a focal point of industry attention due to its exceptional overall economic value and lifecycle cost benefits. Although its initial cost is slightly higher compared to traditional asphalt felt, the long-term cost-effectiveness of synthetic roofing underlayment is drawing increasing interest from developers and homeowners alike.

The primary advantage of synthetic roofing underlayment lies in its lower roof lifecycle cost. Thanks to its superior durability, minimal maintenance requirements, and effective control of leakage and damage risks, this product significantly reduces long-term repair costs and avoids internal damage caused by water infiltration. According to industry data, buildings using synthetic roofing underlayment can save up to 30% of roof maintenance expenses over a 20-year period.

Additionally, high-quality synthetic roofing underlayment can effectively enhance property value and residential comfort. For developers, using such products in roofing systems increases the market competitiveness and appeal of projects. For homeowners, it not only provides reliable protection for the building structure but also creates a comfortable and secure living environment. A real estate agent has revealed that properties with synthetic roofing underlayment tend to receive higher valuations in the second-hand market, with transaction cycles significantly shortened.

As the construction industry places increasing emphasis on both material performance and economic benefits, synthetic roofing underlayment is expected to play a more prominent role in the future market due to its outstanding performance in overall economic value and lifecycle cost.

2025-04-21

DETAIL

The Importance of Roof Materials and How to Choose the Right One

In architectural design, the roof is considered the "guardian" of a house. It not only protects the building from rain, snow, wind, and other natural elements but also affects the overall aesthetics, comfort, and energy efficiency of the home. The choice of roof materials is a crucial aspect of home construction, as it influences the building's appearance, long-term maintenance, and directly impacts the safety and comfort of the residents.

1. Key Factors in Choosing Roof Materials

When selecting the right roof material, several key factors must be considered:

Climate Adaptability

The first consideration when choosing roofing materials is the climate of the area. Different climates have different demands on roof materials. In tropical regions, roofing materials need to provide good insulation to prevent high indoor temperatures. In colder regions, materials need to be durable and waterproof. Choosing materials that are adaptable to the local climate can extend the roof's lifespan and reduce damage from climate changes.

Durability and Maintenance

The roof is one of the most exposed parts of a building, and it faces prolonged exposure to wind, rain, sunlight, and temperature fluctuations. Therefore, the durability of roofing materials is crucial. Some materials may require regular maintenance, cleaning, or repairs, while others can last for decades with little upkeep. When selecting materials, it's essential to consider the maintenance needs and durability, especially for long-term investments in housing.

Aesthetic Appeal and Architectural Style

The roof is not only a functional component of a building but also an important factor in its overall appearance. Choosing the right roofing material should be in harmony with the overall architectural style of the house to provide both functional protection and visual enhancement. Whether the home follows a modern minimalist style or a more traditional country design, the roofing material should complement the overall aesthetic of the structure.

Energy Efficiency and Environmental Impact

Modern buildings increasingly focus on energy efficiency and environmental friendliness, and the choice of roofing material plays a vital role in this. Roofing materials with good insulation and UV protection can regulate indoor temperatures effectively, reducing the need for air conditioning or heating, thus helping families save on energy costs. Additionally, environmentally friendly materials, such as those that are recyclable, help reduce construction waste and lessen the environmental impact.

Budget and Cost-Effectiveness

Aside from the factors mentioned above, budget is another essential consideration when choosing roofing materials. Different materials come at different price points. Some may have a higher initial cost but lower long-term maintenance expenses, while others might be cheaper upfront but require more frequent maintenance or replacement. It’s crucial to balance the initial investment with the long-term costs to ensure the best value within your budget.

2. Essential Roof Material Performance Requirements

Regardless of the type of roofing material chosen, there are several essential performance requirements it must meet:

Waterproofing

The most basic function of a roof is to prevent water infiltration. A high-quality roof must have good waterproofing properties to ensure that, even during heavy storms or extreme weather, rainwater doesn’t penetrate the building and damage its interior.

Insulation and Heat Retention

Insulation is a critical feature of roofing materials, especially in hot or cold climates. The roof should have effective thermal resistance to minimize the impact of external temperature fluctuations on indoor temperatures, improving the comfort level inside the house and reducing the need for air conditioning or heating.

Wind Resistance

In areas prone to high winds, the roof's ability to withstand wind pressure is especially important. Roofing materials need to have good wind resistance to prevent them from being damaged or blown off by strong gusts.

3. The Process of Choosing Roof Materials

Choosing the right roofing material is not a quick decision and requires a comprehensive assessment of various factors. Here is a basic process to follow when selecting roof materials:

Assess Climate Conditions: Understand the local climate, including temperature, rainfall, and wind patterns. Choose roofing materials that are best suited to the climate to enhance the roof’s functionality and longevity.

Set a Budget: Determine a reasonable budget that accounts for both the initial cost of roofing materials and future maintenance expenses. Ensure that the material selected does not exceed the budget and provides good value over the long term.

Evaluate Architectural Style: The roof is an integral part of the house’s exterior design. Select roofing materials that complement the building's overall aesthetic, ensuring that they align with the intended style, whether modern or traditional.

Consider Long-Term Maintenance: Evaluate the maintenance needs of different materials. Some materials may require regular inspections, cleaning, or repairs, while others may be more durable and require less frequent maintenance, reducing overall costs.

Consult Professionals: It’s advisable to consult with professional architects or roofing contractors who can provide expert guidance based on the specific needs, climate conditions, and budget to help you make an informed decision.

4. Conclusion

The roof, as a crucial component of a building, is not only important for its aesthetics and functionality but also for long-term safety, energy efficiency, and cost-effectiveness. Understanding the various functions and performance requirements of roofing materials can help homeowners make more informed choices. Whether building a new home or renovating an existing roof, choosing the right materials will provide long-lasting protection and enhance the comfort and safety of the household.

2025-04-19

DETAIL

Roof Synthetic Underlayment and the Integration with MOUNTAIN BIGFOOT BARRIER: A New Choice for Modern Architecture

As building technology and materials continue to evolve, traditional roofing protection materials are gradually being replaced by high-performance synthetic underlayments. Synthetic underlayments not only provide excellent physical properties but also meet the growing environmental and energy-efficiency demands. In this development, MOUNTAIN BIGFOOT BARRIER, as an emerging roofing solution, is becoming the preferred choice for many construction projects. This article explores the transformation of the roofing industry, market trends, and future innovations through the integration of synthetic underlayments.

1. The Evolution of Synthetic Underlayment: From Traditional Materials to Modern Technology

Traditional roofing protection materials primarily include asphalt, metal shingles, and clay tiles. While these materials have been widely used over the past few decades, they come with disadvantages such as heavy weight, complex installation, and high maintenance costs. As environmental awareness increases and energy-efficiency requirements rise, synthetic materials have gradually replaced traditional materials.

The rise of synthetic underlayment marks a significant innovation in the building industry. From the early use of polyethylene underlayment to modern multi-functional composite underlayments, the evolution of roofing materials reflects not only enhanced physical properties but also a higher standard of environmental responsibility and energy-saving effectiveness. For instance, the use of PVC (Polyvinyl Chloride) and PP (Polypropylene) materials has enabled synthetic underlayments to offer superior durability, longer lifespans, and lower maintenance costs.

2. The Birth of MOUNTAIN BIGFOOT BARRIER Synthetic Underlayment

With the growing demand for high-performance materials in the roofing market, MOUNTAIN BIGFOOT BARRIER was born. This synthetic underlayment is specifically designed for extreme weather conditions, particularly in cold, high-altitude, and snow-prone areas, where its application prospects are promising.

The design of MOUNTAIN BIGFOOT BARRIER is inspired by a deep understanding of the natural environment. It combines innovative composite material technologies to provide multi-layered protection functions in one product. Compared to traditional materials, MOUNTAIN BIGFOOT BARRIER not only enhances roof protection but also reduces installation time and maintenance frequency, making it an ideal choice for modern construction projects.

3. The Demand for Synthetic Underlayment in Modern Architecture

As the effects of global climate change lead to more frequent extreme weather events, architects and engineers must consider how to improve the reliability and durability of roofing systems. From flooding and blizzards to high temperatures and droughts, different climates present varied demands on roofing materials. Synthetic underlayment, such as MOUNTAIN BIGFOOT BARRIER, was created to address these diverse weather conditions. Its emergence not only responds to market needs but also drives the development of building materials towards higher efficiency and intelligence.

4. From Structural Protection to Architectural Aesthetics: The Dual Role of Synthetic Underlayment

As the building industry places increasing importance on aesthetics, roofs must not only be durable and reliable but also align with the architectural vision of the project. The application of synthetic underlayment offers more possibilities in this regard. MOUNTAIN BIGFOOT BARRIER, for instance, is designed to integrate seamlessly with various architectural styles. Its surface design can be customized in terms of color and texture, allowing it to not only protect the roof but also complement the overall aesthetic of the building.

5. Innovation and the Future: The Evolution of Synthetic Underlayment

With continuous technological advancements, future roofing synthetic underlayments may become more intelligent and multifunctional. For example, underlayments that integrate solar panels, temperature-sensing systems, or self-cleaning functions may become a growing trend. As a leader in the industry, MOUNTAIN BIGFOOT BARRIER is expected to further innovate in these areas.

Additionally, as green building and sustainable development become more prominent, the environmental sustainability and recyclability of synthetic underlayments will be further enhanced. We may soon see more synthetic underlayments made from biodegradable materials, further reducing the environmental impact and pushing the entire construction industry towards a more sustainable future.

6. Conclusion: The Future of Roofing Technology

From the early use of asphalt shingles to the modern high-performance synthetic underlayments, roofing technology has come a long way. MOUNTAIN BIGFOOT BARRIER, as an innovative representative of synthetic underlayment, demonstrates how building materials can evolve to meet extreme weather conditions, energy efficiency, and aesthetic demands. With future technological innovations, roofing systems will become even more efficient, and the construction industry will move forward with greater sustainability.

By continuously integrating modern technology with environmental responsibility, synthetic underlayments will no longer be just a protective layer for roofs; they will become a vital component of a multi-functional, efficient, and intelligent building system. For architects, contractors, and end-users, choosing the right roofing underlayment will be one of the keys to success in future construction projects.

2025-04-18

DETAIL

The Evolution of Synthetic Roofing Underlayment: From Market Demands to Technological Innovation

The application of synthetic roofing underlayment in the construction industry is not a coincidence but a result of the evolving demands in the market. From the initial basic requirements of waterproofing and durability, to the current complex functions of integration, intelligence, and environmental friendliness, the development of synthetic roofing underlayment deeply reflects the construction industry’s continuous pursuit of innovation, performance, and sustainability. This article explores the evolution of synthetic roofing underlayment from the perspectives of market demand, technological innovation, and future development directions.

1. The Diversification of Market Demand

The emergence and rapid development of synthetic roofing underlayment is a direct response to the increasingly diverse demands for roofing functions in the market. As the construction industry continues to pursue higher-performance building materials, roofing underlayment has evolved from a simple waterproofing layer to a composite system with many added functions.

Waterproofing Needs: Initially, the design of roofing underlayment focused primarily on waterproofing, particularly in regions with variable climates and frequent rainfall. Early roofing materials, although able to meet basic waterproofing needs, were prone to aging, cracking, and other issues over time. Synthetic materials such as polyethylene (PE) and polyvinyl chloride (PVC) quickly became popular in the construction industry due to their excellent waterproofing properties.

Weather Resistance and Longevity: As building structures and functions became more complex, the demand for roofing underlayment expanded to include longer-lasting weather resistance and enhanced adaptability. Synthetic roofing underlayment, with its UV resistance and anti-aging properties, gradually replaced traditional materials and became the preferred long-term solution. Especially in regions with strong sunlight or extreme temperature fluctuations, synthetic materials effectively withstand harsh weather, extending the lifespan of roofs.

Energy Efficiency and Environmental Needs: With the global energy crisis and growing environmental awareness, energy-efficient building practices became central to design. Roofing no longer served just as a protective layer but was also required to provide insulation and reflect sunlight, reducing energy consumption within the building. Synthetic roofing underlayment’s multi-layered structure and reflective materials not only help improve roof insulation but also reduce the internal temperature of buildings, minimizing air conditioning loads and thus achieving energy savings.

2. Technological Innovation Driving Progress

From waterproof membranes to multi-functional and intelligent roofing protection systems, technological advancements in synthetic roofing underlayment have significantly enhanced its performance. These innovations not only help meet the increasingly complex functional demands but also promote the diversification and efficiency of roofing materials.

The Emergence of Composite Materials: In the late 20th century, the use of composite materials opened up new possibilities for roofing underlayment design. By combining different types of synthetic materials, roofing underlayment can integrate multiple functions within a single system. For example, combining polyethylene and polyvinyl chloride enhances both waterproofing and anti-aging properties, making the material suitable for more complex usage environments.

Self-Cleaning and Anti-Contamination Technology: One of the major innovations in modern roofing underlayment is the application of self-cleaning technology. Through nanocoatings or other surface treatments, synthetic roofing underlayment can prevent dirt, dust, and other pollutants from adhering to the surface, keeping the roof clean. This not only enhances the roof's aesthetic appeal but also reduces maintenance costs and extends the material’s lifespan.

The Rise of Smart Design: With the development of smart building systems, synthetic roofing underlayment is also transitioning towards intelligence. In the future, smart roofing underlayment could automatically adjust temperature and humidity, or even self-repair when damaged. These technological advancements make roofing underlayment more comprehensive in functionality and more responsive to environmental changes in buildings.

3. Challenges and Solutions

Despite significant progress in both technology and performance, the widespread application of synthetic roofing underlayment still faces several challenges. Balancing innovation with cost reduction, enhancing sustainability, and improving recyclability remain key issues in the industry.

Cost and Accessibility: While synthetic roofing underlayment offers clear advantages over traditional roofing materials, the higher initial costs are still a barrier for many projects. To reduce costs, many manufacturers are focusing on optimizing production processes to minimize material waste and driving large-scale production to achieve cost reductions.

Environmental Friendliness and Recyclability: As green building and sustainability become more prominent, the environmental impact and recyclability of synthetic roofing underlayment are gaining increased attention. While many synthetic materials have a long service life, the issue of recycling them at the end of their lifecycle is still a challenge. Developing recyclable materials and improving recycling technologies will be essential for future development.

Adapting to Extreme Climatic Conditions: As climate change brings about more frequent extreme weather events, the adaptability of roofing underlayment becomes increasingly important. For example, in freezing climates, roofing underlayment needs to be resistant to freeze-thaw cycles, while in hot, dry areas, the material must withstand higher temperatures. Material science and structural design will need to continue to innovate to meet these challenges.

4. The Future Trends of Synthetic Roofing Underlayment

The future of synthetic roofing underlayment will focus on intelligence, integration, and sustainability. With the construction industry’s increasing demand for energy-efficient and environmentally friendly buildings, synthetic roofing underlayment will play a more crucial role in shaping the future of building materials.

Integrated and Multi-functional Roofs: Future synthetic roofing underlayment will not only serve as a protective layer but will evolve into a multi-functional integrated system. Roof systems that combine solar power, rainwater harvesting, air purification, and other features will become more prevalent. These roofs not only protect the building from external environmental damage but can also provide energy, enhancing the building's self-sufficiency.

Smart and Adaptive Technologies: As building technologies continue to evolve, so will the intelligence of synthetic roofing underlayment. Future roofing materials may not only adjust temperature and humidity but also monitor the roof's health in real time through sensors, providing early warnings for potential problems and lowering maintenance costs.

Green Building and Sustainability: With increasing attention to global sustainability, the environmental performance and energy efficiency of synthetic roofing underlayment will become more critical. Future roofing materials will focus more on the use of recyclable materials and environmentally friendly production processes, in alignment with increasingly strict green building standards.

Conclusion

The evolution of synthetic roofing underlayment reflects the growing demands for performance, functionality, and sustainability in the construction industry. From a simple waterproofing material to today’s multi-functional, intelligent roofing systems, synthetic roofing underlayment has become an indispensable part of modern construction. With ongoing technological advancements and the increasing diversification of market needs, synthetic roofing underlayment will continue to play a vital role in the future of buildings, driving the construction industry toward smarter, more sustainable, and energy-efficient solutions.

2025-04-17

DETAIL

Enhancing Roof Safety and Durability: Innovative Roof Underlayment Breaks Industry Boundaries

As the construction industry continues to raise its standards for the safety and durability of roofing products, a new roof underlayment is leading the industry transformation. This innovative synthetic roof underlayment combines multiple technological advantages, providing more efficient, safer, and longer-lasting solutions for construction teams and builders.

🔒 Enhanced Safety with Advanced Anti-Slip Design

Roofing work always prioritizes worker safety. The next-generation roof underlayment features a specialized anti-slip surface texture design, ensuring workers can maintain stability even on steep slopes and in wet conditions. This enhanced friction not only helps workers keep their balance but also significantly reduces the risk of injuries due to slipping. Moreover, the underlayment has passed several rigorous safety standard certifications, meeting industry anti-slip requirements and providing additional protection for workers.

🛡️ High Strength and Tear Resistance for Worry-Free Installation

The new roof underlayment has made revolutionary improvements in material performance. By incorporating high-density fiber mesh and reinforced materials, the underlayment's tear resistance and tensile strength have been significantly enhanced. Even when subjected to tool scratches, nail punctures, or foot traffic during installation, the molecular structure of the underlayment prevents minor damage from expanding into larger issues, ensuring the integrity and stability of the entire roof system.

🌪️ Withstanding Extreme Weather Conditions for Year-Round Protection

Roof underlayment performance is crucial in extreme weather conditions. Whether faced with scorching sun, heavy rain, or strong winds, this roof underlayment consistently delivers superior performance. It boasts powerful UV resistance and can withstand high wind loads, ensuring that the roof structure remains stable and protected under any weather condition, providing lasting protection.

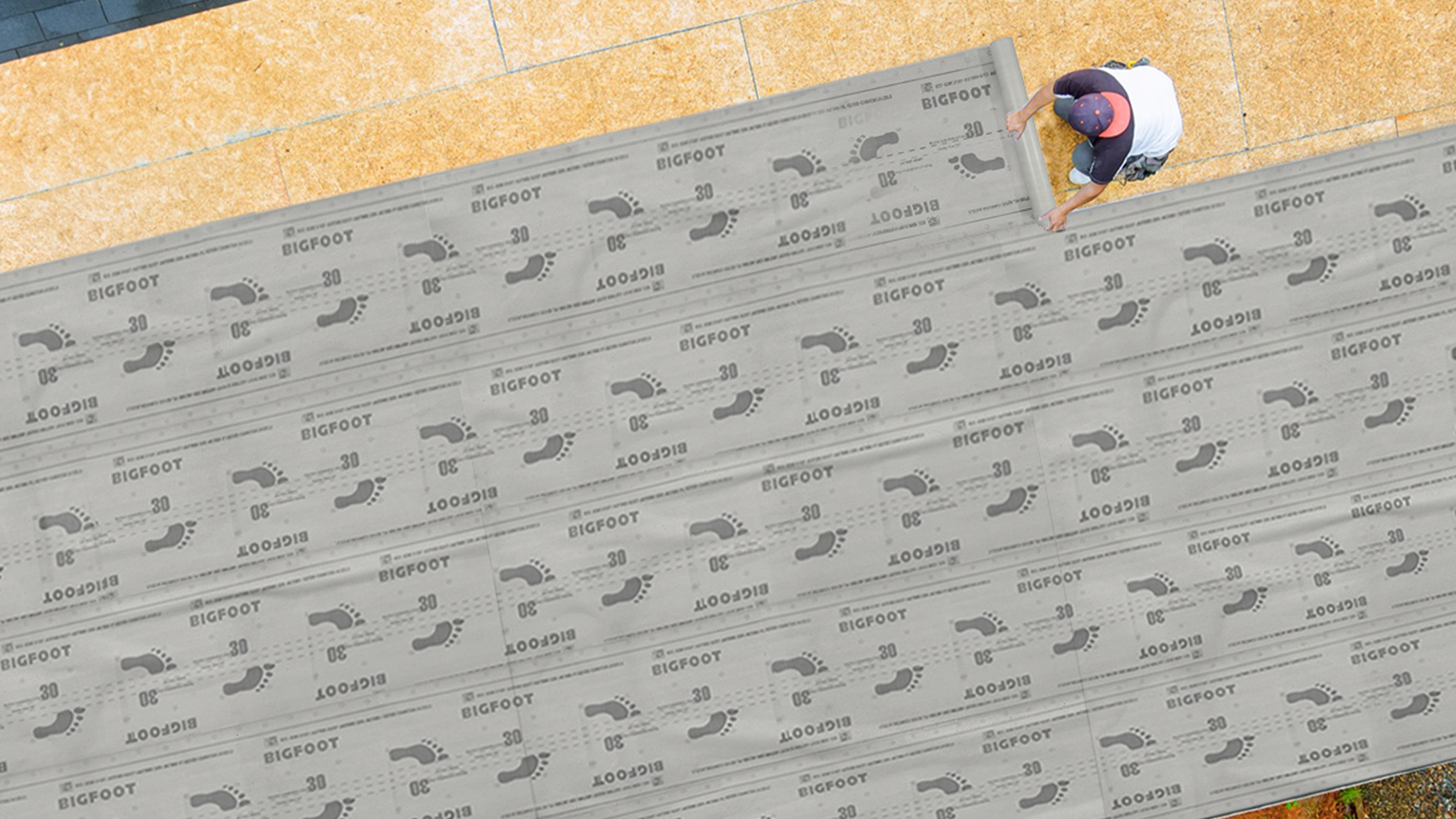

⚙️ More Efficient Installation Experience

When it comes to installation, the new roof underlayment is significantly lighter than traditional materials, making it easier for workers to handle and install, greatly improving installation efficiency. With pre-printed alignment lines and grid patterns, workers can lay down the underlayment more accurately, improving both the precision and aesthetic of the installation.

“Our goal is to provide the construction industry with a safer, more durable, and more efficient roofing solution,” said the product manager. “This new roof underlayment not only breaks through technical barriers but also brings a new level of installation experience to the job site, ensuring worker safety and long-term building protection.”

As the construction industry demands higher-quality roofing materials, this innovative roof underlayment is quickly becoming an essential part of modern building practices, thanks to its exceptional performance and advanced technology.

2025-04-17

DETAIL

MOUNTAIN BIGFOOT BARRIER: High Strength and Tear Resistance Redefine Roofing Underlayment

In roofing construction, durability and strength are key to ensuring long-term protection. To meet the challenges of harsh job site environments and extreme weather conditions, MOUNTAIN BIGFOOT BARRIER offers superior high strength and tear resistance, providing building contractors and installation teams with a more secure and stable foundation for roofing systems.

🔧 Enhanced Fiber Structure Design for Strong Support

MOUNTAIN BIGFOOT BARRIER features an advanced high-density fiber mesh design (such as HDPE mesh or high-strength PP fibers), making its tensile and tear strength far superior to traditional asphalt felt. Some of the underlayment’s tensile strength can reach several hundred pounds, with tear strength ranging from 20 to 50 lbf, offering robust mechanical support to ensure the roofing system remains stable under all conditions.

⚒ Resistant to Installation Damage, Reducing Risk

During roofing installation, underlayment is often subjected to tool scraping, nail punctures, foot traffic, and material handling friction. The molecular structure of MOUNTAIN BIGFOOT BARRIER effectively prevents minor damage from expanding into large tears, greatly reducing the risk of integrity loss during the installation phase. Even under heavy-duty working conditions, it maintains its integrity, ensuring smooth and uninterrupted progress during installation.

💨 Withstands Extreme Wind Loads and Structural Pressure, Enhancing Roof Stability

The exceptional tear resistance of MOUNTAIN BIGFOOT BARRIER allows it to withstand high wind loads during extreme weather, such as storms and hurricanes. In harsh weather conditions or when frequently accessed by maintenance personnel, it maintains the integrity of the roof system, ensuring stability and providing reliable protection for the entire roofing system.

The product manager states, “We are committed to providing high-performance roofing underlayment. MOUNTAIN BIGFOOT BARRIER is designed with exceptional tear resistance and high strength to withstand the harshest job site environments.”

With its powerful tear resistance and strong support, MOUNTAIN BIGFOOT BARRIER has become the ideal choice in the roofing construction industry, helping installation teams tackle extreme conditions and ensuring long-lasting durability and efficiency for roofing systems.

2025-04-16

DETAIL

The Evolution of Roof Synthetic Underlayment and Innovation in Architectural Design

Over the past few decades, building materials have undergone significant technological advancements, especially in the field of roofing design. Roof synthetic underlayment, as part of this transformation, has gradually become an indispensable element in modern architecture. Its development reflects not only the progress of material science but also the innovative thinking within the architectural industry in response to diverse demands.

From the initial simple waterproof layers to the multifunctional synthetic underlayment we have today, the design and functionality of roofs have undergone profound changes. Traditional roofs were typically made of basic materials such as tiles, wood, or metal, with a singular focus on waterproofing and insulation. However, as architectural design concepts expanded, roofs began to take on multiple roles—not just as a shelter, but also contributing to energy efficiency, noise insulation, wind resistance, and more. The synthetic underlayment emerged within this context, meeting the modern architectural demand for both aesthetics and functionality, while also driving the diversification of roof functions.

The introduction of synthetic underlayment, especially in environments with complex climate conditions, has provided architects with greater design flexibility. Its flexibility and adaptability allow designers to pair roof shapes and functions in ways that were previously limited by traditional materials. The versatility of synthetic underlayment has made it an essential tool in high-performance architectural design, meeting not only the basic requirements of a building but also enhancing its adaptability to different environmental conditions.

The technological advancements in roof synthetic underlayment are not limited to improvements in the material itself. With the development of digital design and smart building technologies, synthetic underlayment has gradually become part of smart architecture. In some advanced building projects, synthetic underlayment is even integrated into smart monitoring systems to track parameters like roof temperature, humidity, or air quality, enabling the building to automatically adjust in response to changing conditions to optimize energy use and enhance occupant comfort.

Additionally, as architectural aesthetics and environmental impact gain more attention, the appearance and texture of roof synthetic underlayment are continuously evolving. Whether it's the sleek, modern visual appeal or its harmonious integration with the natural environment, the diversity of synthetic underlayment materials allows the roof to become a prominent feature of the overall architectural design. Many modern architects are increasingly using these materials to break away from the traditional roof shapes, making the roof a standout element of the building.

The evolution of this material reflects the shift in the architectural industry from "single-function" to "comprehensive solutions." It is no longer just a part of the roof but a critical component of the entire building system. With growing attention to green buildings and sustainable design, synthetic underlayment will continue to drive innovation in both roof functionality and aesthetics in future architectural projects.

Looking ahead, with ongoing research and technological breakthroughs, roof synthetic underlayment may expand beyond its current applications, leading to new uses that further enhance the interaction between buildings and the environment. From this perspective, synthetic underlayment is not just an innovation in building materials but a significant breakthrough in architectural thinking.

2025-04-16

DETAIL

MOUNTAIN BIGFOOT BARRIER Redefines Roofing Installation with “Lightweight Efficiency” — Faster Setup, Easier Handling, Enhanced Productivity

In the roofing industry, time, efficiency, and worker safety are always top priorities. MOUNTAIN BIGFOOT BARRIER™ is transforming roof system installation with its lightweight structure, user-friendly application, and smart design details—offering a whole new level of jobsite performance.

🔧 Lightweight Build, Major Advantages

Compared to traditional 30-pound asphalt felt, the BIGFOOT series weighs only 90 to 200 grams per square meter (depending on product grade), making handling safer and transportation more efficient. The significantly reduced load helps lower shipping costs and minimizes worker fatigue and the risk of injury from repetitive lifting and movement.

✂️ Easy Cutting, Fits Complex Structures

Made from a flexible synthetic material, MOUNTAIN BIGFOOT BARRIER™ can be effortlessly cut with standard scissors or utility knives—no special tools required. Installers can quickly adapt the material to roof ridges, skylights, angles, and other complex geometries, increasing overall speed and adaptability on the job.

📐 Printed Alignment Guides for Precision & Speed

Each roll comes with pre-printed alignment lines and grid patterns that serve as visual references for accurate layout. Whether maintaining proper overlap spacing, laying in straight courses, or ensuring a clean, professional finish, these details boost both installation precision and aesthetics, while reducing installation time.

“We’ve always believed that efficient installation is about more than speed—it’s about protecting workers and respecting the quality of the project,” said the Product Director. “BIGFOOT was designed to make installation easier, more accurate, and ultimately faster.”

MOUNTAIN BIGFOOT BARRIER™ is more than just a roofing material—it's an upgrade to the entire professional installation experience. By delivering lightweight efficiency, it’s setting a new standard for modern roofing underlayments.

2025-04-15

DETAIL

MOUNTAIN BIGFOOT BARRIER: Redefining Roofing Underlayment with Long-Term Economic Value

As the construction industry increasingly emphasizes lifecycle cost management, high-performance materials are

steadily replacing traditional solutions. MOUNTAIN BIGFOOT BARRIER™, the synthetic roofing underlayment developed

by Mountain Materials, not only outperforms traditional asphalt felt in performance, but also stands out for its

outstanding economic value and long-term durability—making it the new top choice for modern roofing systems.

💰 Lower Lifecycle Costs — Saving from the Start

Although the initial investment may be slightly higher, MOUNTAIN BIGFOOT BARRIER™ significantly reduces maintenance

and replacement frequency over time thanks to its exceptional durability and aging resistance. It also minimizes repair costs

caused by interior damage from leaks. Compared to traditional asphalt felt that often requires patching, this synthetic

underlayment delivers longer service life and a better return on investment.

“We designed this product with one goal in mind: to help contractors and homeowners achieve true ‘one-time investment,

long-term benefits,’” said the product manager.

🛠 Reduced Labor and Material Waste

With a high-strength waterproof surface and superior structural stability, MOUNTAIN BIGFOOT BARRIER™ provides effective

protection even under harsh weather conditions such as rain, snow, and storms. It prevents common issues like bubbling, curling,

and water leakage—resulting in substantial savings on labor and materials.

🏡 Enhancing Property Value and Living Comfort

A high-quality roof is not only a sign of structural integrity, but also a key factor in attracting buyers and increasing

property value. MOUNTAIN BIGFOOT BARRIER™ offers a strong, durable, and safe foundation for roofing systems,

making homes more secure and comfortable—while giving property owners peace of mind.

2025-04-14

DETAIL

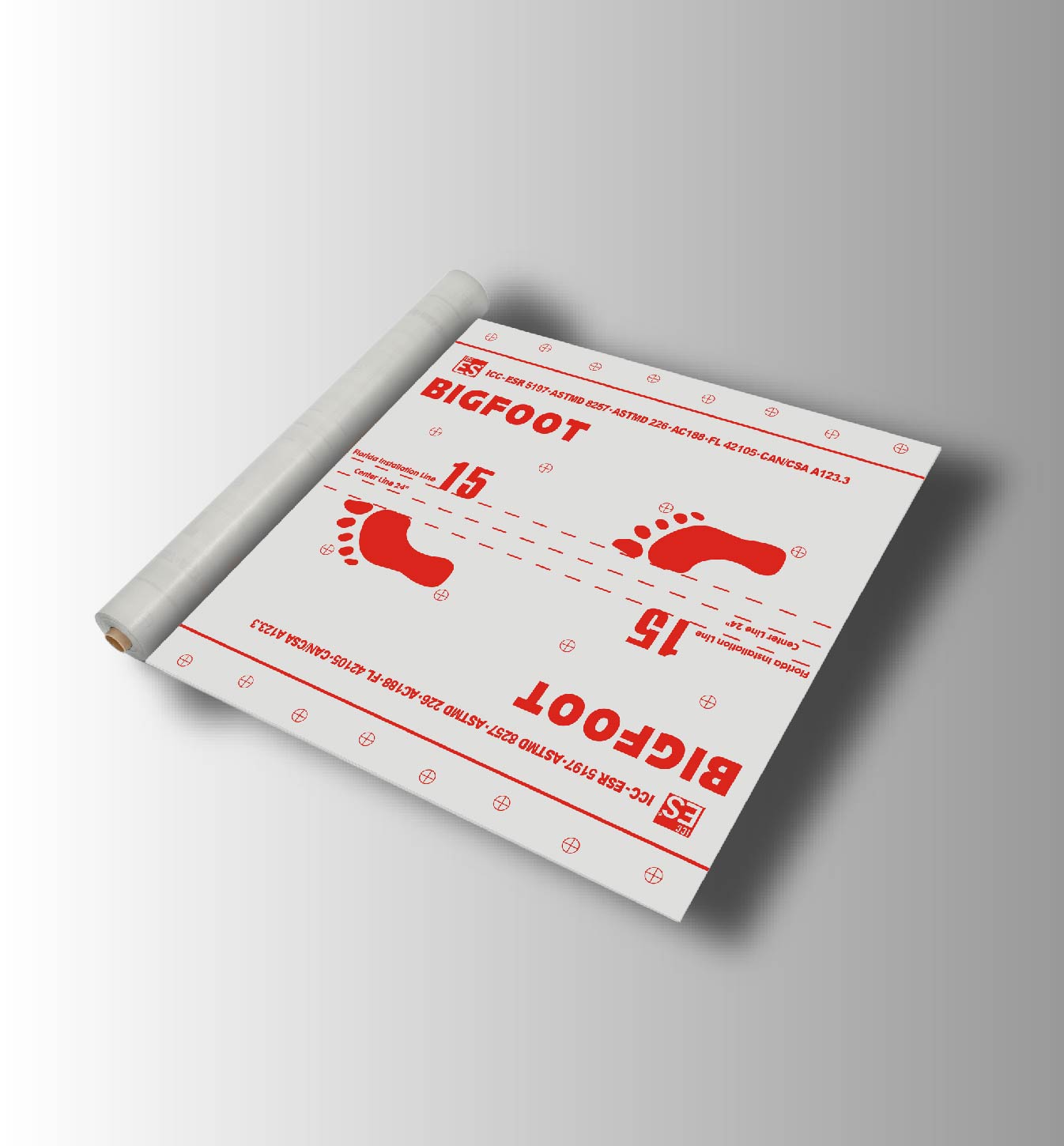

BIGFOOT 15

Learn More

BIGFOOT 15

Learn More

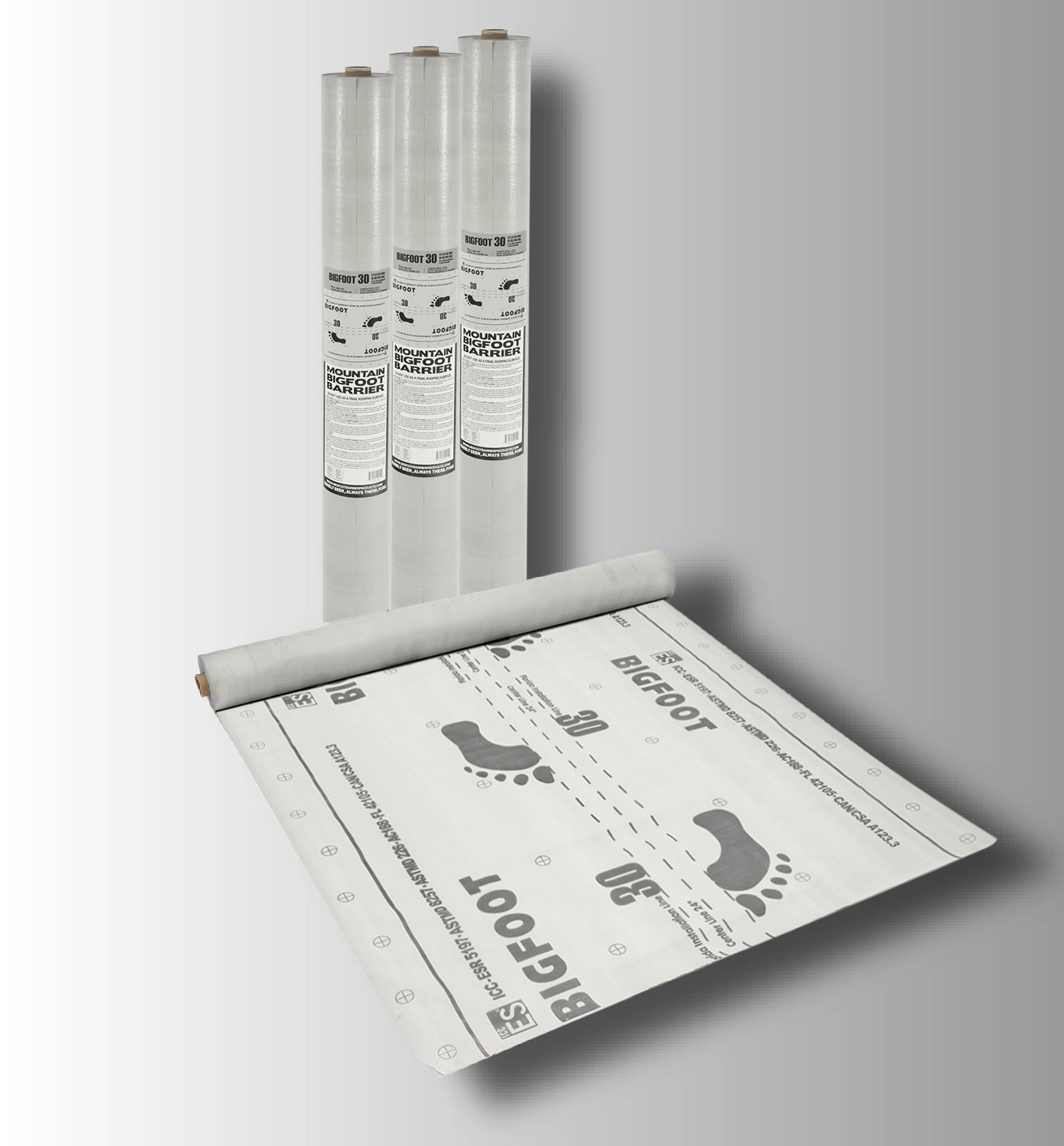

BIGFOOT 30

Learn More

BIGFOOT 30

Learn More

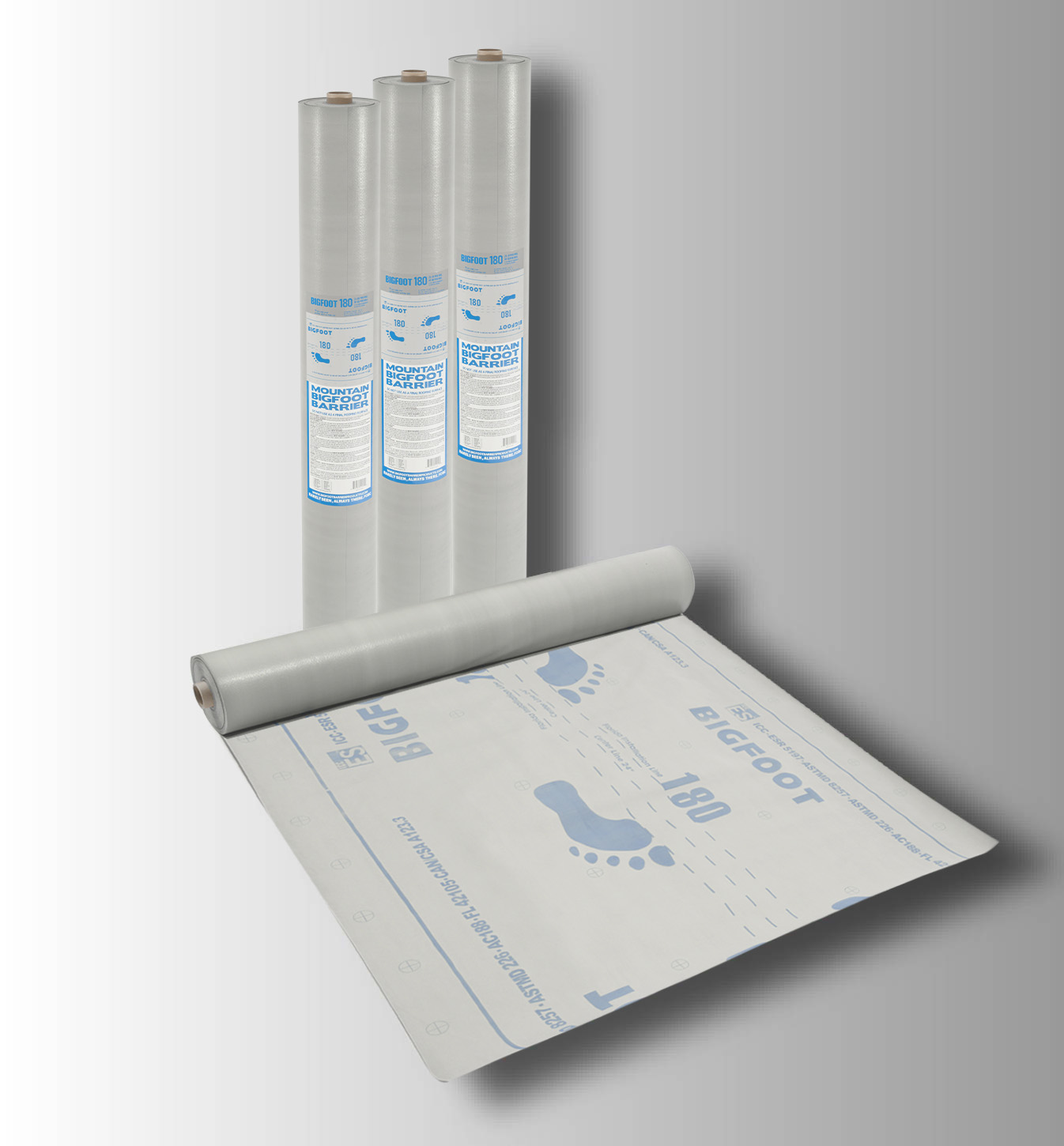

BIGFOOT 180

Learn More

BIGFOOT 180

Learn More

BIGFOOT HD

Learn More

BIGFOOT HD

Learn More

BIGFOOT 15

BIGFOOT 15

BIGFOOT 30

BIGFOOT 30

BIGFOOT 180

BIGFOOT 180

BIGFOOT HD

BIGFOOT HD

Back

Back