The Future of Roofing Underlayment Is Here

For decades, roofing professionals relied on asphalt felt, despite its drawbacks—tearing too easily, absorbing water, and being difficult

to handle. But the industry is evolving, and MOUNTAIN BIGFOOT BARRIER is leading the way with innovative synthetic underlayment

that redefines durability, efficiency, and safety.

Built for Modern Roofing Needs

· Stronger & More Durable – Engineered to withstand extreme conditions, from heavy foot traffic to high winds.

· Waterproof & Mold-Resistant – Unlike traditional felt that weakens when wet, our underlayment repels moisture, keeping roofs dry

and protected.

· Lighter, Faster, Better – Up to 60% lighter than asphalt felt, making it easier to carry and install, saving time and labor costs.

· UV & Weather-Resistant – Designed to handle prolonged sun exposure without breaking down, giving roofers more flexibility in their

schedules.

· Safe & Slip-Resistant – With a high-traction surface, workers get a better grip, reducing the risk of accidents on the job.

MOUNTAIN BIGFOOT BARRIER isn’t just another underlayment—it’s the future of roofing protection. Upgrade today and build stronger,

longer-lasting roofs!

2025-02-17

DETAIL

Elevate Your Roofing Game with MOUNTAIN BIGFOOT BARRIER

Roofing projects demand durability, efficiency, and top-tier protection. That’s why professional roofers and contractors are

making the switch to MOUNTAIN BIGFOOT BARRIER, a high-performance synthetic roofing underlayment designed to outperform

traditional asphalt felt in every way.

Why Choose MOUNTAIN BIGFOOT BARRIER?

✅ Unmatched Strength & Tear Resistance – Built with advanced synthetic materials, it won’t rip or tear even under harsh

weather conditions.

✅ Lightweight & Easy to Install – Say goodbye to heavy, cumbersome felt. Our underlayment is significantly lighter, making

transportation and installation faster and more efficient.

✅ Superior Waterproofing – Unlike asphalt felt, which absorbs moisture and weakens over time, MOUNTAIN BIGFOOT

BARRIER provides a reliable, long-lasting waterproof barrier for your roof.

✅ UV Protection for Extended Exposure – Need extra time before installing shingles? No problem. Our underlayment is

UV-resistant, maintaining its integrity even with prolonged sun exposure.

✅ Slip-Resistant for Added Safety – With a specially engineered anti-slip surface, roofers can work with greater confidence,

even in challenging conditions.

Upgrade to MOUNTAIN BIGFOOT BARRIER and experience the next level of roofing performance!

2025-02-17

DETAIL

A new generation of "guardians" of roof waterproofing

In modern architecture, as an important waterproof material, roof liner plays an indispensable role. In recent years, with the advancement

of material science, synthetic roof liners have gradually become the mainstream choice in the market. This article will take you through the

basic concept of synthetic roof liner, material composition and its application in construction.

What is synthetic roof liner?

Synthetic roof liner is a material used for waterproof roof layer, usually installed under roof covering materials (such as tiles, metal sheets,

etc.), to play a waterproof, moisture-proof and thermal insulation role. Compared to traditional asphalt paper liners, synthetic roof liners

are made of high polymer materials, which have higher strength and durability.

Material composition

The main materials of synthetic roof liner include polypropylene, polyethylene and other high polymer. These materials are processed into

thin films or woven fabrics by special processes, and the surface is coated with a waterproof coating to enhance its waterproof properties.

Some synthetic liners also incorporate reinforcing fibers, such as glass or polyester, to improve their tensile strength and tear resistance.

Manufacturing process

The manufacturing process for synthetic roof liners typically involves the following steps:

Raw material mixing: The high polymer is mixed with additives to improve the properties of the material, such as anti-UV, anti-aging,

etc.

Film forming: The mixed material is made into a film by extrusion or blow molding process.

Coating treatment: A waterproof coating is applied to the surface of the film to enhance its waterproof performance.

Reinforcement treatment: Some liners will add reinforcement fibers to the film to improve its mechanical strength.

Cutting and packaging: The finished product is cut to a standard size and packaged for transport and use.

Application scenario

Synthetic roof liners are widely used in all types of buildings, especially residential, commercial buildings and industrial facilities. It is

usually installed on the lower level of the roof to act as a waterproof barrier, preventing rainwater from penetrating the interior of the

building. In addition, the synthetic liner can also be used for the waterproofing of pitched roofs, flat roofs and complex roof structures.

Performance characteristics

The performance characteristics of synthetic roof liners mainly include:

Waterproof: can effectively prevent rain infiltration, protect the building structure.

Durability: It has a long service life and can resist the influence of environmental factors such as ultraviolet light and temperature change.

Lightweight: Compared to traditional materials, synthetic liners are lighter and easier to transport and install.

Environmental protection: Some synthetic liners can be recycled to reduce the impact on the environment.

Future development trend

With the continuous improvement of material performance requirements in the construction industry, the research and development of

synthetic roof liners is also continuing to advance. As an important material in modern architecture, the scientific principle and application

value of synthetic roof liner are worth further understanding. With the continuous progress of technology, synthetic liners will play a more

important role in the field of building waterproof, providing a strong guarantee for the safety and durability of buildings.

2025-02-15

DETAIL

New Roof Synthetic Liner: The Anti - Slip Pioneer, Reshaping Roof Safety and Efficiency

In the current context where the construction industry places increasing importance on safety and efficiency, a brand - new

roof synthetic liner has made a grand entrance and quickly attracted attention in the building materials field. With its outstanding

anti - slip performance, it not only addresses the long - standing safety hazards that have plagued roof construction and

maintenance but also, with its excellent comprehensive performance, brings all - round value enhancement to construction projects.

With the rapid development of the construction industry, the safety risks in roof operations have become increasingly prominent.

Traditional roof liners have poor anti - slip performance when facing adverse weather conditions such as moisture and icing, and

workers are prone to slipping when working on the roof. However, our new roof synthetic liner has completely reversed this situation

through breakthrough material innovation and precise surface texture design. It provides reliable safety guarantees for construction

and maintenance personnel, achieving a qualitative leap in anti - slip effects.

The research and development of this liner have gathered the wisdom of top - notch scientific research teams. They have delved

deep into the principles of friction, precisely optimized the molecular structure of the materials and the micro - morphology of the

surface, ensuring that it can generate strong and stable friction with various types of shoe soles. Whether it is the scouring of strong

winds and heavy rains or the cold winter covered with thick snow, it can always maintain excellent anti - slip performance, making

roof operations safer and more stable.

In practical applications, the new anti - slip liner has been used in many major construction projects. The old - roof renovation

project, as one of the first projects to adopt this product, has achieved remarkable results after its use. A construction worker

shared, "After using this synthetic liner, the safety factor during our roof construction has been greatly improved. Slipping accidents

have almost disappeared, and the construction efficiency has also been significantly increased, providing strong support for the

smooth progress of the project."

In addition to its excellent anti - slip performance, this liner also has outstanding durability and waterproof performance. Its

unique material formula enables it to resist the influence of natural factors such as ultraviolet rays and chemical erosion,

effectively extending the service life of the roof and greatly reducing maintenance costs.

Experts in the construction industry have highly appraised this product, believing that it will reshape the industry standards

for roof construction and maintenance and is expected to become the first choice for future roof materials. With the continuous

improvement of construction safety standards, our new anti - slip roof synthetic liner will surely continue to play an important

role in the construction field, contributing to ensuring the safety of construction workers and improving the quality of buildings.

Choosing our roof synthetic liner means choosing safety, efficiency, and long - lasting value. Learn more product information now

and embark on your journey to construction safety.

2025-02-15

DETAIL

Why MOUNTAIN BIGFOOT BARRIER Leads the Market in Roofing Protection

Over the past few decades, the roofing underlayment industry has undergone a major transformation. From traditional asphalt felt to

high-performance synthetic roofing underlayment, market demand has driven continuous technological advancements. In this

transformation, MOUNTAIN BIGFOOT BARRIER has quickly become a leading brand, thanks to its outstanding performance and reliability.

Why Is Synthetic Roofing Underlayment Replacing Asphalt Felt?

1️⃣ Superior Durability – Traditional asphalt felt tears easily and deforms when exposed to moisture. MOUNTAIN BIGFOOT BARRIER,

made with high-polymer synthetic materials, resists tearing, withstands UV exposure, and maintains long-term stability.

2️⃣ Faster and Easier Installation – With its lightweight design, workers can carry and install it more efficiently, completing more square

footage per day.

3️⃣ Exceptional Waterproofing – Unlike asphalt felt, which absorbs moisture over time and loses its protective function, MOUNTAIN

BIGFOOT BARRIER features a specialized waterproof coating that ensures lasting protection.

4️⃣ Eco-Friendly and Safer – Asphalt felt contains bitumen, which can release harmful fumes. Our synthetic underlayment is asphalt-free,

making it both environmentally friendly and safer for workers.

Industry Recognition: The Market Trend Is Clear!

More and more roofers and contractors are switching to synthetic roofing underlayment because it reduces long-term maintenance

costs while providing superior roof protection. MOUNTAIN BIGFOOT BARRIER stands out as a top choice in this growing trend, earning

widespread recognition for its reliability and performance.

Want to stay ahead in the roofing industry? Choose MOUNTAIN BIGFOOT BARRIER for a stronger, longer-lasting roof!

2025-02-14

DETAIL

The Roofer’s Choice – Why We Stopped Using Traditional Asphalt Felt

For roofing professionals, every day is spent working at heights, installing and repairing roofs. Every step matters for

efficiency and safety. Choosing the right underlayment doesn’t just affect installation speed—it determines the durability

of the entire roofing system.

“We used to rely on asphalt felt, but it caused too many problems.”

• Too heavy to carry – Moving dozens of rolls of traditional felt each day felt like lifting bricks. It added unnecessary strain on workers.

• Tears too easily – During installation, even a slight pull could cause it to rip, especially in windy conditions.

• Absorbs moisture and deforms – After rain or humidity, asphalt felt would absorb water, swell, and affect the overall roof quality.

• Slippery and unsafe – Asphalt felt has a smooth surface, increasing the risk of workers slipping, especially in wet conditions.

“But everything changed when we switched to MOUNTAIN BIGFOOT BARRIER.”

✅ Lightweight for easier handling – With 40%-60% less weight than traditional felt, workers can transport and install

it effortlessly, covering more area in a day.

✅ Tear-resistant, even in windy conditions – Its reinforced strength prevents tearing or blowing away, ensuring a smooth

and secure installation.

✅ All-weather protection – The waterproof layer prevents leaks, while UV resistance keeps it from deteriorating even after

prolonged sun exposure.

✅ Slip-resistant for safer installation – The special anti-slip surface provides superior traction, reducing the risk of accidents.

“Now, our entire crew uses MOUNTAIN BIGFOOT BARRIER, and we’ll never go back.”

If you’re a roofer or contractor, you know what makes a product truly reliable. Choose MOUNTAIN BIGFOOT BARRIER

for easier installations, better protection, and a roof that lasts!

2025-02-14

DETAIL

How Revolutionary Roof Protection Materials Are Redefining Building Waterproofing Standards

In the ever-evolving field of construction technology, a new polymer-based waterproof barrier is revolutionizing the roofing industry.

This innovative product, less than one-third the thickness of traditional materials yet offering superior protective performance, is redefining

how buildings withstand environmental challenges.

Materials scientists highlight that the core of this technology lies in its multi-layer composite design. By combining different polymer

films with reinforced grids, the product retains the flexibility of soft materials while achieving fabric-like tear resistance. Accelerated aging

tests in laboratories show that its resistance to UV degradation is more than three times that of traditional asphalt-based materials,

ensuring longer-lasting waterproof performance under intense sunlight.

Compared to conventional waterproof membranes, this groundbreaking material demonstrates several significant advantages. Its weight

per square foot is reduced by approximately 60%, not only lowering transportation costs but also increasing daily installation coverage by

nearly 40%. In terms of extreme weather adaptability, the material maintains stable performance within a temperature range of -40°C to

120°C and has successfully passed hurricane-level wind uplift tests.

From an environmental perspective, manufacturers employ closed-loop production processes, reducing energy consumption by over 30%,

with 99% of waste materials being recyclable. Notably, the material is entirely free of volatile organic compounds, eliminating air pollution

during installation.

Building code experts recommend that property owners focus on three key technical indicators when selecting waterproof materials:

puncture resistance rating, moisture permeability coefficient, and seam strength. Leading products in the market typically feature a

three-layer protective structure, where the reinforced grid in the middle layer directly impacts the material's overall mechanical

performance, and the mineral coating on the surface provides additional abrasion resistance.

With the increasing frequency of extreme weather events, the construction industry's demand for reliable waterproof solutions continues

to grow. This new protective material not only extends the lifespan of roofing systems but also supports rapid repairs through its modular

installation features, driving the industry toward greater efficiency and sustainability. Industry forecasts predict that the market penetration

rate of such products in North America's new construction and renovation sector could exceed 50% within the next five years.

2025-02-07

DETAIL

Roof Synthetic Underlayment: Durability Shapes a New Guarantee for Building Waterproofing

Recently, with the continuous improvement of the waterproof requirements in the construction industry, roof synthetic underlayment

has gradually become a new favorite in the building waterproofing field due to its excellent durability.

Traditional roof waterproof materials are prone to problems such as aging, cracking, and damage under long - term exposure

to sunlight, rain, temperature changes, and mechanical stress. These problems lead to a decline in waterproof performance and

require frequent repairs or even replacements. However, the new - type roof synthetic underlayment adopts advanced polymer

materials and unique production processes, which greatly enhance the durability of the product.

It is understood that the polymer materials selected for these synthetic underlayments have excellent weather resistance

and can effectively resist the erosion of natural factors such as ultraviolet rays, ozone, and acid rain, slowing down the

aging rate of the materials. At the same time, their unique molecular structure endows the underlayment with excellent

flexibility and tear resistance, enabling it to remain intact and less likely to crack when facing the expansion and contraction

deformation of the roof due to temperature changes.

In terms of the production process

advanced composite technology enables the various layers of materials of the underlayment

to be closely combined, forming a solid whole, which further enhances the durability of the product. In addition, some synthetic

underlayments are added with special anti - aging agents and stabilizers, fundamentally extending the service life of the product.

In practical applications

the durability of roof synthetic underlayment has been fully verified. The roof of Mr. and Mrs. Smith's

house uses a new - type synthetic underlayment. After years of use, it still maintains good waterproof performance, provides

reliable protection for the building, and greatly reduces the later maintenance costs.

Experts said that the high durability of roof synthetic underlayment not only provides a more reliable guarantee for building

waterproofing but also conforms to the concept of sustainable development, reducing the waste of resources and environmental

pollution caused by the frequent replacement of waterproof materials. With the continuous progress of technology and the

further reduction of costs, roof synthetic underlayment is expected to be widely used in more construction projects, promoting

the building waterproofing industry to move towards a new stage of development.

2025-02-07

DETAIL

Innovative Anti-Slip Surface Technology for Roof Synthetic Underlayment Significantly Enhances Construction Safety and Efficiency

Recently, a major breakthrough in anti-slip surface technology for roof synthetic underlayment has brought a new solution to

the construction industry, significantly improving safety and efficiency. This innovative technology not only effectively reduces

the risk of workers slipping during roof operations but also extends the lifespan of roofs by enhancing the durability and stability

of the underlayment.

Technical Highlights: Comprehensive Improvement in Anti-Slip and Safety Performance

Traditional roof underlayment materials are prone to causing worker slips under wet or slippery conditions, increasing construction

risks. The new synthetic underlayment, however, incorporates advanced anti-slip surface treatment technology. Through unique

texture design and material formulation, it significantly increases the friction coefficient. Even in rainy or oily environments, the

underlayment surface provides reliable grip, ensuring safe working conditions for workers.

Additionally, this technology integrates UV resistance, corrosion resistance, and anti-aging properties, allowing the underlayment

to maintain excellent performance even under extreme weather conditions. This not only reduces maintenance costs but also further

enhances the overall safety of roofs.

Wide Range of Applications, Driving High-Quality Development in the Construction Industry

The anti-slip surface technology for roof synthetic underlayment is suitable for various types of building roofs, including residential,

commercial, and industrial buildings. Its lightweight design and easy installation features significantly shorten construction cycles

and reduce labor costs. Moreover, the technology complies with international safety standards, providing construction companies

with a more competitive solution.

Broad Market Prospects, Promoting Green Transformation in the Industry

With the increasing global demand for construction safety and sustainability, the anti-slip surface technology for roof synthetic

underlayment is expected to become a new industry standard. Its eco-friendly materials and energy-saving characteristics align

with the development trends of green building, injecting new momentum into the sustainable development of the construction

industry.

About Us

We, ABP (American Building Products), are a high-tech enterprise dedicated to the research and development of innovative

building materials. We focus on providing safe, efficient, and environmentally friendly roof solutions to global customers. In the

future, we will continue to drive technological innovation, contributing to the safety and sustainable development of the

construction industry.

For more information, please visit our website.

2025-02-06

DETAIL

The Reliable "Companion" for Roof Protection: The Wonders of an Innovative Material

In the field of architecture, the importance of the roof is just like the foundation of a building. It is the key to resisting the erosion of the

external environment and safeguarding the indoor space. Among the various components of the roof, the underlayment plays an

indispensable role. Today, let's take a good look at an innovative material that is gradually changing the pattern of roof protection -

the underlayment made of synthetic materials.

Let's first review some of the shortcomings of traditional roof underlayments. Traditional underlayments often fall short in terms of

waterproofing. Just imagine that during heavy rain or when snow melts, water can easily break through the "defense line" of traditional

underlayments and seep into the internal structure of the roof. Over time, the wooden frames of the roof may become damp, moldy,

and then rot, seriously threatening the overall stability of the roof and greatly shortening its service life.

Moreover, traditional underlayments also perform unsatisfactorily in dealing with external wear and tear. Daily exposure to wind and sun,

the impact of falling branches from time to time, plus the friction and pulling during the construction process can all cause traditional

underlayments to be damaged or torn. It's like a big "gap" has been opened in the roof's protective layer, and various hidden dangers will

follow one after another.

Let's talk about its excellent waterproof performance first. This is one of its highlights. The synthetic underlayment uses special synthetic

materials and advanced manufacturing techniques to create an extremely fine and continuous waterproof layer. Whether it's a drizzle, a

heavy rainstorm driven by strong winds, or the water flow generated by the slow melting of thick snow, it can act like a loyal "guard" and

firmly block these waters outside the roof, ensuring that the inside of the roof remains dry and comfortable all the time. It's like putting an

indestructible "waterproof coat" on the roof, which greatly enhances the roof's ability to resist water damage.

Now let's discuss its anti-wear ability. The synthetic underlayment has strong toughness and high strength. Even when frequently subjected

to external impacts, such as the impact of debris blown by strong winds and the friction caused by construction workers walking on the roof,

it is not easy for it to be damaged or torn. It seems that it comes with a solid "shield" that always protects its integrity, thus providing

continuous and reliable protection for the roof.

In terms of installation, the synthetic underlayment also shows many advantages. It is relatively lightweight, making it easy and convenient

to transport. Unlike some traditional underlayments that are heavy and require a lot of manpower and material resources to move. Moreover,

its installation process is simple and straightforward, enabling construction workers to lay it on the roof more efficiently, which can greatly

save construction time and is quite helpful for promoting the progress of the entire construction project.

From an environmental protection perspective, the synthetic underlayment also keeps up with the pace of the times. During the production

process, it often selects environmentally friendly raw materials and pays attention to reducing energy consumption and waste generation.

Even some synthetic underlayments can be recycled after use, which undoubtedly contributes to environmental protection and also conforms

to the concept of sustainable development in the construction industry.

As for the safety performance, the synthetic underlayment also performs excellently. As we all know, during roof construction, workers

need to work on an inclined plane at a certain height, and the risk of slipping is not small. However, the synthetic underlayment has a

good anti-slip surface, which can provide construction workers with safer working conditions. It's like laying a "non-slip mat" on the roof,

allowing workers to work more at ease.

All in all, the underlayment made of synthetic materials, with its advantages in waterproofing, anti-wear, convenient installation,

environmental protection, and safety, is gradually becoming a popular choice for roof protection in the construction industry. With the

continuous progress of science and technology, it is believed that it will continue to be optimized and upgraded, bringing better and

more reliable roof protection effects to our buildings, so that every roof can firmly safeguard our living space.

2025-02-06

DETAIL

Performance Advantages and Cost-Benefit Analysis of Synthetic Roof Underlayment in Building Protection

In the development of the construction industry, the roof, as a critical protective "barrier" of a building, demands materials of superior

quality and performance. Currently, synthetic roofing underlayment is emerging as a standout among various roofing materials, offering

numerous benefits for the long-term use and value enhancement of buildings.

Helping Reduce the Lifecycle Cost of Roofs

In the past, traditional asphalt felt was a common choice for roof construction. However, with advancements in building technology,

synthetic roofing underlayment has demonstrated superior performance. Although the initial investment for synthetic roofing

underlayment is slightly higher than that of traditional asphalt felt, when considering the entire lifecycle cost of the roof, the

advantages of synthetic roofing underlayment become significantly apparent.

Synthetic roofing underlayment boasts exceptional durability, capable of withstanding prolonged exposure to sunlight, rain, wind, and

other natural elements without easily suffering damage or aging. In contrast, traditional asphalt felt may develop cracks, peeling, and

other issues over time due to various external factors, leading to roof leaks and necessitating frequent repairs and partial material

replacements. Thanks to its outstanding performance, synthetic roofing underlayment effectively reduces long-term repair costs and

prevents internal damage caused by water infiltration, thereby lowering the overall cost from installation to eventual decommissioning.

This provides tangible economic value to building owners and users.

Significantly Reducing Repair and Maintenance Costs

Once a roof leaks, a series of subsequent problems can arise, including water-soaked and moldy interiors, compromised insulation

affecting indoor temperature regulation, and corrosion of structural components due to moisture. However, synthetic roofing

underlayment acts like a robust defense line, significantly reducing the risk of roof leaks with its excellent waterproofing and puncture

resistance.

Many buildings using synthetic roofing underlayment require minimal maintenance over extended periods, nearly achieving an ideal

"zero maintenance" state. Compared to traditional roofing materials that require regular inspections, repairs, and ongoing material

purchases, this undoubtedly saves considerable operational costs for building management. It allows building managers to allocate

resources more efficiently to other critical areas, ensuring the overall smooth operation of the building.

Enhancing Property Value and Living Quality

For developers, choosing high-quality synthetic roofing underlayment is an effective way to create premium properties and enhance the

added value of real estate projects. For homeowners, it is a crucial guarantee of a comfortable living environment and improved quality of

life.

From an aesthetic perspective, roof systems using synthetic roofing underlayment give buildings a more orderly and impressive

appearance, showcasing high-quality architectural imagery and undoubtedly increasing the property's market appeal. On a deeper level,

it provides residents with a dry, comfortable, and safe living space, free from the worries of roof leaks, allowing them to fully enjoy the

warmth and comfort of home life. In the real estate market, properties equipped with synthetic roofing underlayment are often more

attractive to buyers and hold greater advantages in value assessment and transactions, significantly enhancing their overall value.

In summary, synthetic roofing underlayment is rapidly becoming a popular choice in the construction industry due to its significant

advantages in optimizing long-term roof cost-effectiveness, simplifying maintenance, and enhancing property value and living quality.

With ongoing technological innovations and improvements, synthetic roofing underlayment is expected to play an even more important

role in future construction projects, providing a solid "overhead defense" for more buildings.

2025-02-05

DETAIL

Beware! The Hazards of Asphalt Roofing Underlayment Cannot Be Ignored

Recently, as the environmental protection and safety issues of building materials have received increasing attention, the potential

hazards of asphalt roofing underlayment have triggered extensive discussions within and outside the industry. The specific hazards

are as follows:

Environmental Hazards

Production Pollution: During the production process of asphalt roofing underlayment, a large amount of volatile organic

compounds (VOCs) such as benzene and toluene are released, which aggravates air pollution, easily forms photochemical

smog, and disrupts the ecological balance.

Waste Pollution: Abandoned asphalt roofing underlayment is difficult to degrade, occupies land resources for a long time,

and may also release harmful substances into the soil and water bodies, causing secondary pollution.

Human Health Hazards

Health Impairment of Construction Workers: During installation, the heated asphalt emits a pungent odor containing carcinogens

such as polycyclic aromatic hydrocarbons. Prolonged exposure increases the risk of respiratory diseases and even cancer for

construction workers. Many construction workers have reported symptoms such as coughing and shortness of breath after work.

Impact on Residents' Health: During the use of the roof, high temperatures cause the asphalt to continuously emit harmful gases,

which enter the room through vents, causing discomfort such as dizziness and fatigue among residents.

Roof Structure Hazards

Aging and Waterproofing Issues: Asphalt roofing underlayment ages rapidly. Over time, it tends to harden, crack, reducing the

waterproof performance and shortening the service life of the roof.

Material Compatibility Issues: It has poor compatibility with some roof materials, which may cause corrosion of metal components

and affect the overall stability of the roof.

An expert in building environmental protection, pointed out that the research, development, and application of environmentally

friendly roof underlayment materials should be promoted as soon as possible to reduce the reliance on asphalt roofing underlayment.

Relevant departments also need to strengthen supervision and improve the environmental protection and safety standards of building

materials. Currently, some regions have started to explore new environmentally friendly roof underlayment materials to replace asphalt

products. The exposure of the hazards of asphalt roofing underlayment has sounded the alarm for the construction industry, and it is

urgent to promote the industry to develop in a more green and safe direction.

2025-02-05

DETAIL

BIGFOOT 15

Learn More

BIGFOOT 15

Learn More

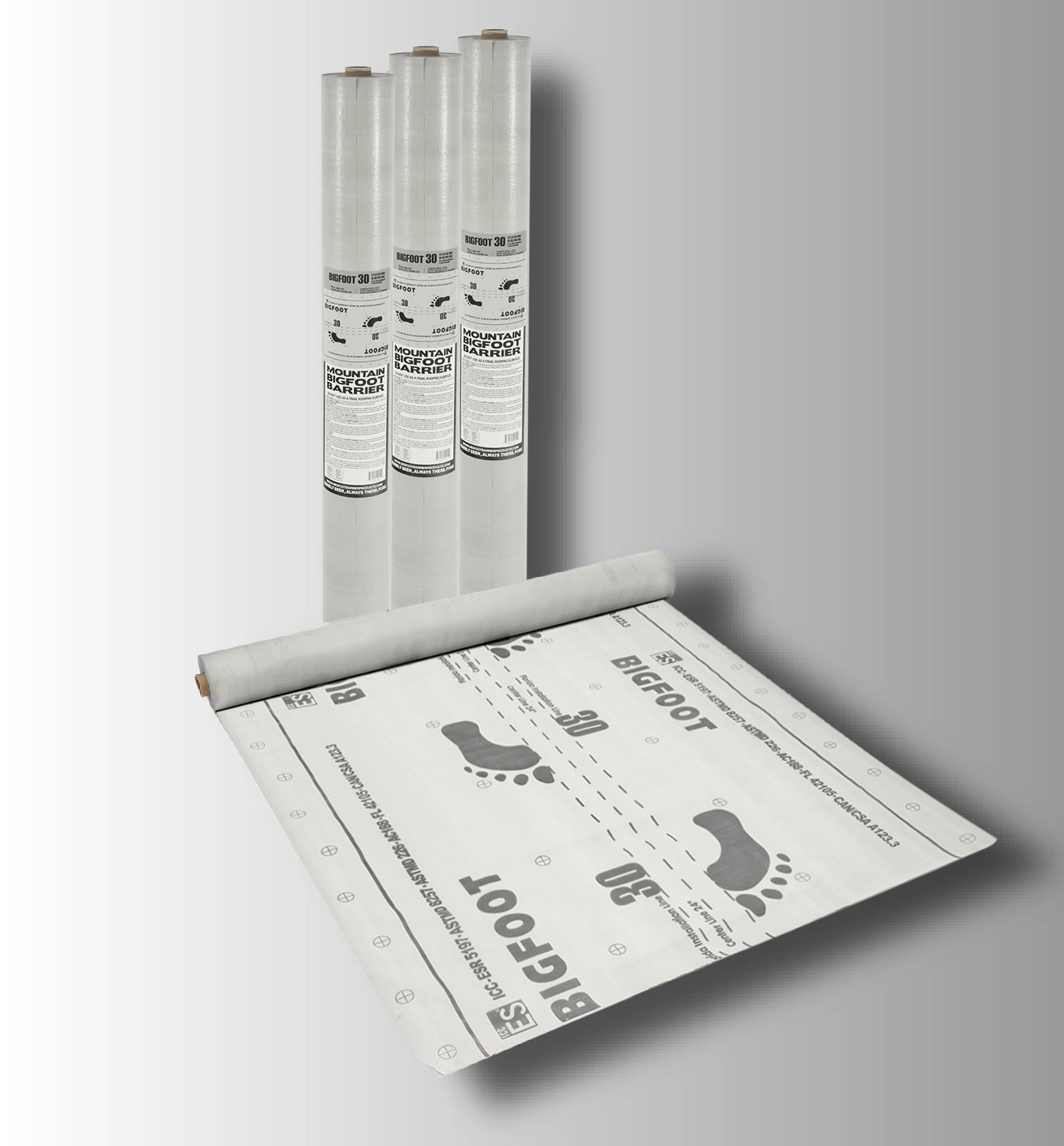

BIGFOOT 30

Learn More

BIGFOOT 30

Learn More

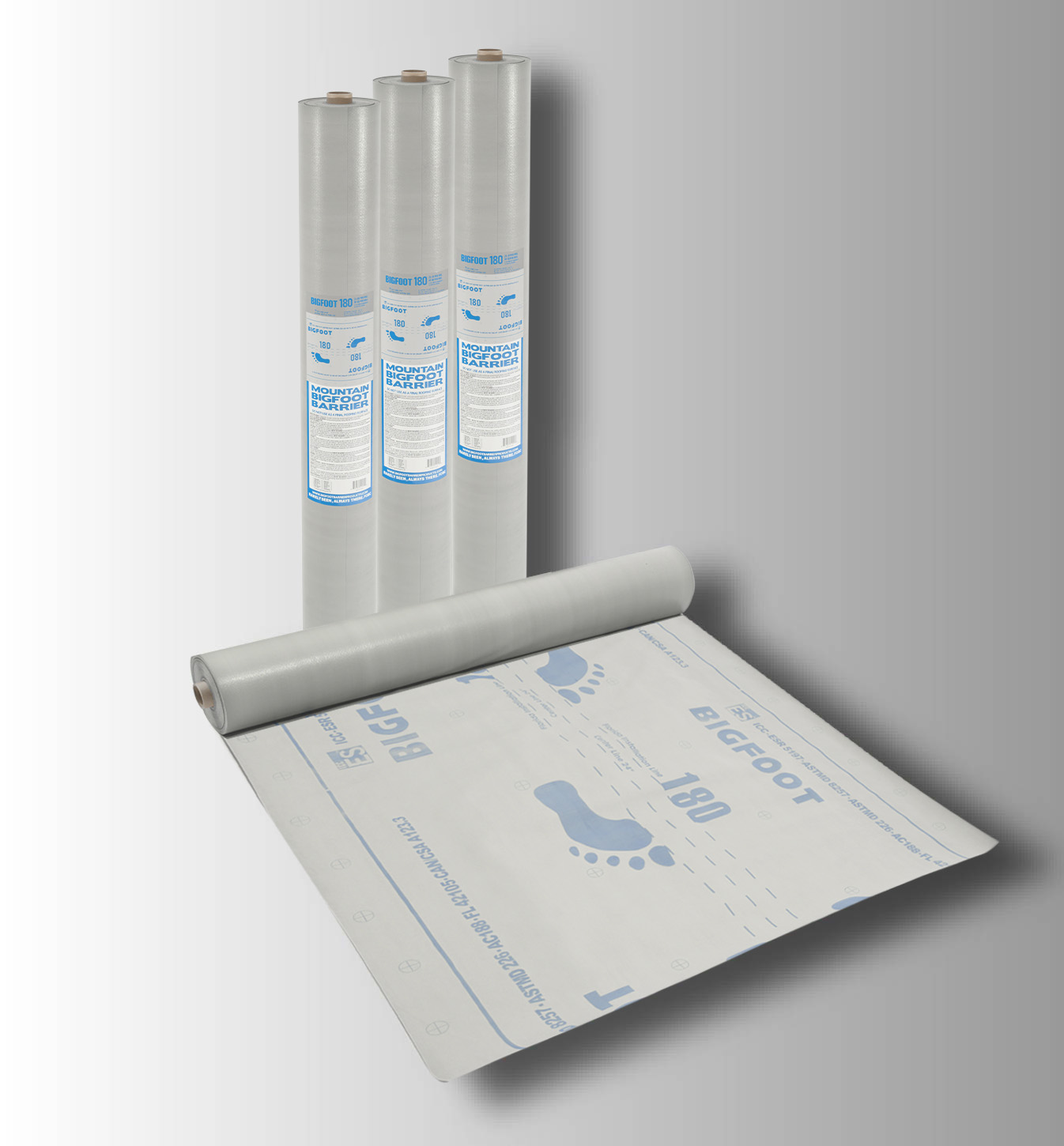

BIGFOOT 180

Learn More

BIGFOOT 180

Learn More

BIGFOOT HD

Learn More

BIGFOOT HD

Learn More

BIGFOOT 15

BIGFOOT 15

BIGFOOT 30

BIGFOOT 30

BIGFOOT 180

BIGFOOT 180

BIGFOOT HD

BIGFOOT HD

Back

Back