MOUNTAIN BIGFOOT BARRIER Sets a New Benchmark in Roofing Underlayment with Exceptional Thermal and Dimensional Stability

As extreme weather events become increasingly common, roofing systems demand more reliable base-layer protection. With outstanding thermal and dimensional stability, synthetic underlayment like MOUNTAIN BIGFOOT BARRIER™ is emerging as a top-tier solution, offering builders and roofing contractors a more durable and professional installation experience.

Built for Extreme Temperatures – Stability That Lasts

Through both lab tests and real-world applications, MOUNTAIN BIGFOOT BARRIER has demonstrated exceptional temperature resistance:

Excellent Cold Resistance: Remains flexible at temperatures as low as -40°C, without becoming brittle or cracking.

Heat-Resistant and Stable: Withstands prolonged exposure to 80°C–90°C heat without melting, flowing, or distorting.

This dual-temperature stability ensures that MOUNTAIN BIGFOOT BARRIER maintains its protective performance in both freezing northern climates and scorching southern heat zones.

Material Innovation for Dimensional Reliability

Compared to traditional asphalt felt, the synthetic material used in MOUNTAIN BIGFOOT BARRIER features minimal thermal expansion and contraction. Even under constant temperature fluctuations, the material maintains its shape and integrity—effectively preventing:

Wrinkling or bubbling

Warping or curling edges

Uneven surfaces that can compromise waterproofing

“Our design process focused heavily on how temperature changes can affect installation quality,” said the Product Director. “MOUNTAIN BIGFOOT BARRIER™ helps contractors avoid rework caused by material distortion, improving both efficiency and structural reliability.”

Built to Protect High-Performance Projects

From frigid mountain homes to sun-drenched commercial developments, MOUNTAIN BIGFOOT BARRIER’s thermal and dimensional stability makes it a trusted solution for complex roofing challenges. It not only shields roofs from environmental stress but also strengthens the long-term durability of the entire building system.

2025-04-12

DETAIL

Synthetic Roof Underlayment: From Technological Innovation to Future Development

In the rapid development of modern building technology, synthetic roof underlayment has increasingly become a key material for enhancing the performance of roofing systems. Although roof underlayment is often considered an auxiliary building material, its role in roofing systems is multifaceted and far-reaching. With technological advancements, synthetic roof underlayment has seen continuous innovation in terms of materials, functionality, and environmental sustainability, driving the development of the construction industry and providing more possibilities for future roof designs.

The technological evolution of synthetic roof underlayment reflects the rapid progress in materials science. From the initial simple waterproof layers to today’s high-performance synthetic underlayments with multiple functions, the innovations behind these materials are not just manufacturing process improvements but also a deep understanding of building environmental needs. Modern synthetic roof underlayments are typically made from synthetic polymers or composite materials, which perform significantly better than traditional materials in areas such as UV resistance, chemical corrosion resistance, and temperature tolerance. These technological advancements allow synthetic roof underlayment to provide sustained protection in harsh weather conditions and extend the lifespan of the roof.

At the same time, the design of synthetic roof underlayment is gradually evolving toward more intelligent and integrated solutions. For example, some high-end synthetic underlayment materials are now capable of integrating with a building’s energy systems to optimize roof thermal management and improve the building’s overall energy efficiency. This innovation has been applied not only in commercial buildings but is gradually penetrating residential architecture as well. With the help of intelligent roofing systems, synthetic roof underlayment can monitor the roof’s condition in real-time, alerting to potential damage or leaks, thereby improving the building’s safety and maintenance efficiency.

In the future, the development of synthetic roof underlayment may further incorporate cutting-edge technologies. For example, the application of nanotechnology could enable underlayment to possess self-healing capabilities and enhanced protective performance. Imagine a roof underlayment that can automatically repair small cracks or damage, not only extending the roof’s service life but also significantly reducing maintenance costs and frequency. Additionally, with the growing focus on sustainability and green building practices in the construction industry, the production processes and material choices for synthetic roof underlayment will increasingly prioritize environmental friendliness and resource recycling. This shift not only responds to environmental regulations but also meets consumer demand for healthier buildings and green products.

The multifunctionality of synthetic roof underlayment is also becoming increasingly recognized by architects and engineers. In the past, the role of underlayment was mainly concentrated on waterproofing and insulation, but today, its function has expanded into broader areas. For instance, synthetic roof underlayment can help reduce noise pollution from the roof, especially in areas undergoing rapid urbanization. The soundproofing properties of synthetic underlayment can effectively reduce the penetration of external noise, improving indoor comfort. This feature is particularly useful in highly trafficked urban areas or buildings located near industrial zones.

Furthermore, synthetic roof underlayment has made breakthroughs in enhancing the aesthetic appeal of buildings. As materials technology advances, modern synthetic underlayment can offer more design options, not only meeting functional requirements but also complementing the building’s exterior. Through innovations in color, texture, and surface coatings, synthetic roof underlayment can help architects achieve more personalized and diverse roof designs. This provides greater flexibility in the design of modern building facades and enhances the overall visual effect of the building.

The future development of synthetic roof underlayment is also closely linked to the digital transformation of the global construction industry. With the widespread use of technologies such as Building Information Modeling (BIM), the production, design, installation, and even maintenance of synthetic roof underlayment can become more precise and efficient. BIM technology allows designers to accurately simulate every component of the roofing system, including the selection of underlayment materials and performance evaluation, thus optimizing the overall roof design. Through digital technologies, the design and installation of underlayment will become more precise and intelligent, further improving the overall performance and safety of the building.

In conclusion, synthetic roof underlayment is not just a simple building material; it has evolved into a highly versatile component of roofing systems, offering multiple functions such as waterproofing, insulation, soundproofing, and UV protection. As material science and building technologies continue to advance, future synthetic roof underlayment will continue to play an important role in intelligent, sustainable, and aesthetic design. With the maturation of these technologies, synthetic roof underlayment is expected to play an increasingly critical role in the global construction market, driving the industry towards greater efficiency, sustainability, and intelligence.

2025-04-12

DETAIL

How to Choose and Use the "Invisible Shield" for Your Roof?

Is your roof facing these issues? Water leaking through the gaps between roof tiles during rain, condensation on the ceiling in winter, or

worrying about tiles being blown off during strong winds? All these problems are related to a layer of protection you can't see—the

synthetic roof underlayment. It may not be as noticeable as the tiles, but it quietly takes on the important tasks of waterproofing,

insulation, and wind resistance. Today, let’s talk about how this "shield" works and how you can choose and use it for your roof.

The Core Functions of Roof Underlayment: The "Invisible Guardian

Simply put, synthetic roof underlayment is a flexible material placed between the roof structure and the tiles (or metal panels, concrete). It

mainly does three things:

When rainwater leaks through the gaps between roof tiles, the underlayment acts like a "waterproof membrane," blocking the water and

guiding it to the drainage system, preventing it from seeping into the roof interior (like the ceiling or insulation). Especially in tricky areas

like roof corners, skylights, and chimneys, the underlayment can flex and cover the gaps that tiles fail to cover.

In summer, it reflects part of the solar heat, reducing the temperature inside the house; in winter, it insulates the interior by preventing heat

loss through the roof and preventing condensation (water droplets formed when warm indoor air meets cold roof surfaces) from damaging

the structure. During strong winds, the underlayment helps grip the tiles or the roof structure through friction, reducing the risk of the tiles

being blown off. In the case of hail, it acts like a "cushion" that absorbs the impact, protecting the roof from damage.

How to Choose the Right Underlayment? Consider These Three Key Scenarios

Choose Based on Roof "Shape": Flat Roof vs. Sloped Roof

Flat Roof (e.g., top-floor platforms): Prone to water accumulation, so choose materials that are waterproof and resistant to aging,

like high-density polyethylene (similar to thick plastic bags but more durable), which can withstand being submerged in water for long

periods.

Sloped Roof (e.g., tile roof): Pay attention to whether the surface of the underlayment is "rough enough." If it’s too smooth, the tiles

may slip. It’s better to choose a textured material (like an anti-slip mat) to increase friction.

Choose Based on Climate: Rainy South vs. Cold North vs. Windy Coastal Areas

South (humid, rainy): Choose underlayment with a "water-repellent coating" (similar to the surface of a lotus leaf, where rainwater

doesn’t stay) and an internal structure that is "breathable," allowing moisture from inside the roof to escape, preventing mold growth.

North (cold): The underlayment needs to be "soft" enough to resist cracking in low temperatures, like rubber gloves in winter that

remain flexible. Otherwise, it will crack when frozen, and its waterproofing will fail.

Coastal/Windy Areas (high salt content): The material should be corrosion-resistant (salt accelerates aging). It’s best to choose one with

UV-resistant coating, so it won’t deteriorate after years of sun and wind exposure.

Choose Based on Roof "Material": Tile vs. Metal vs. Concrete

Tile Roof: The underlayment needs to be slightly flexible to conform to the curves of the tiles while also being tear-resistant (so it won’t

tear if stepped on during tile installation).

Metal Roof: Metal expands and contracts with temperature changes, so the underlayment should have "elasticity" to move with the metal

without cracking. Otherwise, temperature fluctuations can cause it to tear.

Concrete Roof: Focus on "puncture resistance." For example, when workers drop tools on the roof during construction, the underlayment

could be punctured, so choose one with a "reinforced layer" (such as fabric with a grid embedded for better puncture resistance).

Installation and Maintenance: These Tips Will Make It Last Longer and Save You Trouble

Key Installation Tips

Ensure the base is flat: If the roof base is uneven, the underlayment will have wrinkles, which can crack over time and allow water to leak in.

So, make sure to level the roof before installation.

Seal the seams properly: The underlayment is installed in sections, and the seams must be sealed with heat-welding (like fusing plastic) or

special adhesive tape. Never leave gaps.

Fixing Method Based on Roof Type: On sloped roofs, nails are commonly used (make sure to use nails with washers to prevent tearing the

underlayment). On flat roofs, adhesive or heavy objects (like concrete blocks) are often used to prevent the underlayment from being blown

away.

Regularly check the tiles: Broken tiles can damage the underlayment, so inspect your roof annually and repair any cracks promptly.

Avoid piling things on the roof: Heavy objects on the underlayment for long periods can cause localized wear, especially on flat roofs.

Avoid placing flower pots or other objects on the roof.

What to do if water leaks?: If water leaks indoors, first check the roof surface for visible damage, then check areas like skylights and

downspouts—these areas are most prone to leaks if the underlayment was not installed properly.

How to Choose the Right Underlayment? Keep These Three "Checks" in Mind

Check the "Thickness": Thicker is not always better! For general home use, a thickness of 1-2mm is sufficient. Too thick a material may not

conform well to the roof shape and can increase costs.

Check the "Flexibility": Take a small sample and bend it. If it recovers without cracks when you release it, it indicates the material will remain

flexible at low temperatures and won’t become brittle.

Check for "Certification": A reputable product will have national standards (e.g., GB/T 23457) or international certifications (e.g., ASTM),

especially a "weather resistance" test report, which tells you how long the underlayment will last before aging.

Conclusion: Don’t Let Your Roof "Work Sick," Choosing the Right Underlayment Matters

Although synthetic roof underlayment is invisible, it plays a crucial role in protecting your home. If you choose the right one, it can help you

block out rainwater, save on repair costs, and extend your roof's lifespan by more than ten years. Next time you’re renovating or replacing

your roof, remember to ask your contractor: "Which underlayment are we using? Is it suitable for our climate and roof type?" Pay attention

to the unseen details, and your home will be safer and more comfortable.

2025-04-11

DETAIL

MOUNTAIN BIGFOOT BARRIER™ Leads the Way to a Greener Roofing Era — Protecting Every Inch of Your Building with Sustainable Innovation

As the construction industry places growing emphasis on sustainability, Mountain Materials proudly introduces a

new roofing underlayment that combines high performance with eco-conscious design—MOUNTAIN BIGFOOT

BARRIER™. This innovative product is engineered to deliver greener, longer-lasting protection for modern roof

systems.

In traditional construction, roofing underlayment is often overlooked when it comes to environmental impact. But

MOUNTAIN BIGFOOT BARRIER™ changes the game. Made from recyclable, high-performance synthetic materials,

and designed with a non-asphalt, low-carbon manufacturing process, it offers exceptional protection while

significantly reducing environmental burden.

♻ Key Environmental Advantages:

✅ Asphalt-free and Non-toxic: Free from harmful chemicals, making it safer for workers and better for the environment

✅ Recyclable Materials: The underlayment itself is recyclable, helping reduce construction waste

✅ Lightweight Design = Lower Emissions: Lighter than traditional felt, resulting in more efficient and lower-emission transportation

✅ Extended Product Lifespan: Built to last, reducing the need for replacements and cutting down on resource consumption

“We’ve always asked ourselves—what makes a truly great roofing underlayment? It should protect homes and also the

planet,” said the Product Director. “MOUNTAIN BIGFOOT BARRIER™ isn’t just a high-performance product—it’s a promise

to a greener future.”

🌍 A Partner in Green Building

MOUNTAIN BIGFOOT BARRIER™ has already been widely adopted across residential and commercial projects, especially

by developers and contractors focused on sustainability and aiming for LEED certification.

From mountaintop cabins to urban high-rises, this underlayment offers contractors a durable, eco-responsible solution

that strengthens roof systems while supporting the industry’s shift toward sustainable construction.

2025-04-11

DETAIL

Lightweight and Tough – MOUNTAIN BIGFOOT BARRIER Redefines Roofing Underlayment Installation

On the roofing job site, efficiency and safety go hand in hand. With its lightweight yet durable synthetic construction, MOUNTAIN

BIGFOOT BARRIER delivers unprecedented ease and speed for roofing professionals, making it the ideal next-generation underlayment

solution.

“When designing this product, we focused on two key principles: usability and high performance. MOUNTAIN BIGFOOT BARRIER not

only delivers exceptional waterproofing, slip resistance, and weather protection—it also significantly reduces labor strain thanks to its

lightweight structure, enhancing overall jobsite efficiency,” said the Product Director.

Five Key Advantages of Lightweight Design:

Easier Handling – Each roll weighs less, making lifting, carrying, and laying easier while reducing worker fatigue

Faster Installation – Easy to cut and roll out, perfect for quick, large-area applications

Lower Transportation Costs – Lighter rolls reduce shipping expenses and are ideal for large-scale logistics planning

Greater Flexibility – Easier to maneuver on complex roof shapes, with superior adaptability and fit

Enhanced Worker Safety – Minimizes the risk of strain-related injuries from heavy lifting, improving jobsite safety

Lightweight Without Compromising Performance

Despite its light weight, MOUNTAIN BIGFOOT BARRIER doesn't compromise on performance. It offers high tear resistance, 180-day UV

exposure protection, durability down to -40°F, and a textured anti-slip surface. This perfect balance between strength and ease of use

allows for smooth installation with strong, long-lasting protection.

Engineered for Professional Installation

From residential rooftops to commercial buildings, from urban high-rises to remote mountain cabins, MOUNTAIN BIGFOOT BARRIERempowers roofing crews to reduce rework, improve build quality, and deliver long-term protection for homeowners—all while speeding

up the installation process.

2025-04-10

DETAIL

Synthetic Roof Underlayment: An Indispensable Protective Layer in Modern Architecture

Synthetic roof underlayment has become an increasingly important component of modern building roof systems, gaining widespread

recognition among architects, contractors, and property owners. It plays a crucial role not only in protecting the roof physically but also

in enhancing the performance, durability, and long-term maintenance cost of the roof system. As the construction industry places greater

emphasis on sustainability and environmental concerns, the application of synthetic roof underlayment has expanded, evolving from merely

an additional protective layer to an essential factor for improving roof performance and reducing maintenance costs.

Key Role in Roof Protection

The roof system is directly exposed to the elements. Whether it’s intense ultraviolet radiation, heavy rainfall, or drastic temperature

fluctuations, the roof needs to exhibit exceptional durability. Synthetic roof underlayment is designed precisely to address these needs.

It not only offers excellent waterproofing but also helps regulate temperature, protecting the roof surface from the harsh impacts of the

environment.

Furthermore, synthetic roof underlayment possesses strong UV resistance, which helps to prevent material degradation and aging caused

by prolonged exposure to sunlight. Traditional roofing materials are prone to cracking and degradation under intense UV rays, which can

lead to reduced waterproofing and even leakage. Synthetic underlayment, made from UV-resistant synthetic materials, helps to delay this

process and ensures the roof’s long-term stability.

Enhancing Overall Roof System Performance

Synthetic roof underlayment offers significant advantages in protection, but it also plays an important role in improving the overall

performance of the roof system. First, the flexibility and elasticity of synthetic materials allow the underlayment to provide more uniform

support. This is especially important for roofing materials that are more susceptible to environmental changes, such as metal or membrane

roofs. Synthetic underlayment can effectively prevent roof materials from warping or cracking due to thermal expansion and contraction,

reducing the risk of material damage.

In addition, synthetic roof underlayment contributes to both thermal insulation and soundproofing. With increasing energy efficiency

demands in buildings, roof insulation has become particularly important. Due to its unique structure and material properties, synthetic

underlayment can improve the roof’s thermal performance, reducing the load on air conditioning during summer months and thus

lowering energy consumption. For buildings where soundproofing is crucial, such as commercial offices or residential homes, synthetic

underlayment effectively reduces the transmission of external noise, creating a quieter indoor environment.

Sustainability and Environmental Benefits

As environmental awareness grows, the construction industry is increasingly favoring sustainable, eco-friendly building materials. In this

context, the environmental properties of synthetic roof underlayment are of particular importance. Many synthetic roof underlayments

are made from recycled materials or are produced with low-carbon processes, aligning with modern green building practices and helping

to reduce the carbon footprint of the construction industry.

Moreover, the recyclability of synthetic roof underlayment makes it a material that aligns with the principles of a circular economy. Once its

service life is over, synthetic roof underlayment can be recycled and reused, thus reducing resource waste and environmental pollution. In

some high-end and green building projects, the use of eco-friendly synthetic roof underlayment has become a growing trend.

Long-Term Cost Efficiency

Although synthetic roof underlayment may require an initial investment, its long-term cost benefits are clear. First, the high durability and

UV resistance of synthetic underlayment significantly reduce the frequency of roof maintenance and replacements. Compared to traditional

underlayment materials, synthetic roof underlayment has a lower maintenance cost in extreme weather conditions and over extended periods,

minimizing expensive repairs caused by roof damage.

Additionally, due to its excellent waterproofing and insulation properties, synthetic roof underlayment can reduce energy waste caused by

leaks or temperature fluctuations. For instance, in colder climates, the roof's improved insulation can lower heating requirements, while in

hot climates, the enhanced waterproofing and thermal properties can reduce air conditioning costs, leading to energy savings and reduced

long-term operational costs.

Conclusion

As a modern building material, synthetic roof underlayment is becoming an indispensable part of roof systems due to its exceptional

performance, environmental benefits, and adaptability. As the construction industry continues to emphasize sustainability and long-term

efficiency, the use of synthetic roof underlayment will become more widespread. It not only improves the durability and functionality of

roof systems but also supports the green development goals of the building industry. In the future, synthetic roof underlayment will

continue to play an irreplaceable role in architectural design, becoming a core element of modern roofing systems.

2025-04-10

DETAIL

The Key Role of Roofing Synthetic Underlayment in Roofing Projects

In roofing projects, the use of synthetic underlayment is often overlooked, but it is an essential part of the roofing system. It plays a crucial

role in protecting the roof structure, improving overall performance, and extending the roof’s lifespan. This article will explore the role of

synthetic underlayment in roofing construction, its applications, and how it can affect the challenges encountered during the installation

process.

1. The Function of Synthetic Underlayment in Roofing Construction

Synthetic underlayment is primarily used to prevent water infiltration, protect the roof structure, and provide thermal insulation. However,

during the construction process, its role becomes even more significant. Here are a few of the key functions of synthetic underlayment in

roofing construction:

Waterproofing

One of the most important considerations in roofing construction is effectively preventing water infiltration. Whether constructing a new

roof or performing a renovation, water infiltration can significantly damage roof materials and lead to structural corrosion. Synthetic

underlayment provides an additional layer of protection to the roof, preventing rain, melting snow, and moisture from penetrating the

roof structure. Its waterproofing capabilities not only enhance the roof’s protective capacity but also reduce maintenance and repair costs.

Improving Construction Efficiency

The design and installation of synthetic underlayment are typically simple and straightforward, which plays a key role in accelerating the

construction process. Many synthetic underlayment materials are self-adhesive or lightweight, allowing construction workers to install

them quickly, without the need for extensive tools or time. For large-scale roofing projects, the use of synthetic underlayment can greatly

improve construction efficiency and reduce project timelines.

Preventing Structural Damage

Roof structures are often exposed to external environmental factors during construction, such as wind, rain, and temperature fluctuations.

Synthetic underlayment provides a protective layer that minimizes the negative effects of these factors on the roof. It helps prevent exposure

of the roof structure to unstable weather conditions, reducing the risk of damage during construction.

2. Installation Requirements for Synthetic Underlayment

Although installing synthetic underlayment is typically straightforward, it’s important to follow certain installation requirements to ensure

it performs at its best. Below are some common installation considerations:

Preparing the Roof Surface

Before installing underlayment, it is essential to clean and prepare the roof surface. Construction workers should ensure the roof is free

from debris, dust, grease, moisture, or any other substances that could affect the adhesion of the underlayment. Proper surface

preparation ensures the underlayment is firmly bonded to the roof, delivering the best protective performance.

Ensuring Proper Fit and Coverage

When laying the underlayment, it is crucial to ensure that it fits tightly and evenly across the entire roof. Any unevenness or gaps can

compromise the waterproofing function. During installation, workers must ensure that the underlayment lies flat without wrinkles or

looseness. If the underlayment does not tightly adhere to the roof, it may lead to water infiltration and reduce the overall protective effect.

Seam Treatment

Seam treatment is a critical aspect of underlayment installation. During installation, all seams should be sealed properly to avoid any gaps

where water could potentially seep through. For self-adhesive underlayment, workers must also ensure that the adhesive bonds effectively

to prevent seams from opening due to wind or other external forces.

3. Common Issues and Solutions

Although synthetic underlayment plays a key role in roofing construction, improper installation or choosing the wrong material can lead

to several issues. Below are some common problems and solutions:

Issue 1: Underlayment Delamination

If the synthetic underlayment is not properly bonded to the roof or the adhesive used is inadequate, delamination may occur, where

the underlayment separates from the roof surface. This exposes the roof, reducing its waterproofing effectiveness. To avoid this issue,

it’s recommended to choose underlayment materials with strong adhesive properties and ensure that installation steps are followed

carefully.

Issue 2: Underlayment Damage

Underlayment damage may occur due to improper installation, material aging, or external weather conditions, such as UV exposure or

strong winds. If damage occurs, it can compromise the roof’s waterproofing capacity. To solve this problem, regular inspection of the

underlayment is necessary. Any signs of damage should be addressed immediately to prevent further deterioration.

Issue 3: Wrinkling of the Underlayment

If the synthetic underlayment is not installed evenly, wrinkles may form, reducing its effectiveness in waterproofing. Construction workers

need to ensure the underlayment is installed smoothly and evenly, paying close attention to prevent any wrinkles, which could lead to a

decrease in the waterproofing effect.

4. Maintenance and Care for Synthetic Underlayment

Although synthetic underlayment is highly durable, regular inspection and maintenance are still necessary to ensure the roof’s long-term

performance. Below are some common maintenance recommendations:

Regular Inspections

Routine inspections of the roof and underlayment are essential, especially after strong winds or heavy rainfall. Workers should check the

integrity of the underlayment to ensure there are no tears, wear, or other forms of damage.

Cleaning the Underlayment Surface

To ensure the long-term effectiveness of synthetic underlayment, cleaning the surface regularly is important. Debris, leaves, or dirt can

obstruct the underlayment’s ventilation and drainage functions, reducing its overall performance. Routine cleaning will help extend its

service life.

Conclusion

Synthetic underlayment plays a vital role in roofing projects, not only enhancing the roof’s waterproofing and insulation capabilities but

also improving construction efficiency and minimizing the risk of structural damage during installation. While it is often an "invisible hero"

of the roofing system, its importance in the construction process should not be underestimated. Choosing the right synthetic underlayment,

following proper installation steps, and performing regular maintenance will ensure that the roof remains secure, durable, and well-protected

for years to come.

2025-04-09

DETAIL

MOUNTAIN BIGFOOT BARRIER — Revolutionizing Roofing Safety with Innovative Anti-Slip Technology

Innovative Anti-Slip Design for Safe, Worry-Free Installation

Roofing installations often involve steep slopes, strong winds, rain, snow, and other extreme weather

conditions, which significantly increase the risk of slips and falls. MOUNTAIN BIGFOOT BARRIER uses

a patented anti-slip surface design that greatly enhances friction with the worker's footwear. Even in wet,

rainy, or snowy conditions, workers can maintain stable footing, reducing the risk of slips and injuries.

“Safety on the roof has always been a top priority for us. When designing MOUNTAIN BIGFOOT BARRIER,

we specifically focused on worker safety. This anti-slip underlayment significantly reduces the likelihood of

accidents,” said Product Director. “Whether on a steep roof or during harsh weather, MOUNTAIN BIGFOOT

BARRIER provides a safer, more stable working environment for the crew.”

Key Anti-Slip Features:

Enhanced Anti-Slip Surface – Improves friction, ensuring stable movement on even slippery roof surfaces

Efficient Friction Design – Reduces the risk of slipping, especially in rainy or snowy conditions

Durability – Maintains exceptional anti-slip performance even after prolonged exposure to harsh weather

Ideal for Steep Roofs – Provides additional safety for steep slopes, suitable for both residential and commercial projects

Protecting Your Workforce

With the anti-slip technology of MOUNTAIN BIGFOOT BARRIER, the installation team can work more

efficiently and confidently. Workers no longer have to worry about the risk of injury from slips, allowing

the project to proceed faster. We understand that every minute counts in roofing, and minimizing

accidents means projects are completed on time, creating a safer, more productive work environment

for the team.

Industry-Leading Installation

As the roofing industry’s safety standards continue to rise, MOUNTAIN BIGFOOT BARRIER offers

a revolutionary solution for roofing projects. Not only does it help contractors reduce delays and

rework caused by accidents, but it also boosts client trust in the quality of the construction. Every

worker’s safety matters, and the integrity of every building needs to be safeguarded. MOUNTAIN

BIGFOOT BARRIER is the strong bridge between both.

2025-04-09

DETAIL

Roof Synthetic Underlayment: A Multi-functional Protective Material in Construction

Roof synthetic underlayment has gradually become a key component in modern building roof installation systems. While it is typically used

as a base layer under roofing tiles or other covering materials, its role in construction goes beyond merely protecting the roof. The design

and use of roof synthetic underlayment often depend on specific geographical conditions, climate, and roof types. Unlike traditional

materials such as asphalt underlayment, synthetic underlayment offers more variety and detailed applications during its use.

The application of roof synthetic underlayment is not limited to residential roofs; it is increasingly used in commercial and industrial

building roofs. In commercial projects, the selection of roof underlayment is often closely related to the building's functional requirements.

For example, some commercial buildings may require underlayment that also has fire-resistant properties or stronger wind resistance to

address various risks and challenges. Different types of underlayment materials are adjusted based on project needs to meet higher

requirements for the roofing system.

During the application of roof synthetic underlayment, the installation method varies depending on the roof design. For pitched roofs,

the underlayment must take into account the drainage and breathability of the tiles to ensure that water can flow off smoothly and avoid

accumulation. For flat roofs, the underlayment must not only address waterproofing but also meet requirements for durability, anti-aging

properties, and sealing performance. These different needs drive continuous innovation and optimization in both roofing underlayment

materials and installation techniques.

Interestingly, as the demand for energy-efficient and sustainable buildings increases, the direction of roof synthetic underlayment research

and development is also shifting. In the past, many underlayment materials were heavily dependent on fossil fuels or chemical processes,

but modern roof synthetic underlayment production is increasingly focusing on environmental friendliness. For instance, some

manufacturers are now using renewable resources as raw materials to produce more environmentally friendly and biodegradable roofing

underlayment products This not only aligns with the trend of green building but also opens up broader application opportunities for roof

synthetic underlayment in the future.

In addition to the building structure itself, the choice of roof synthetic underlayment is also closely related to the local climate. Roofs in

tropical, cold, or humid regions may require different types of underlayment materials to cope with extreme temperature and humidity

variations. For example, in humid areas, underlayment with strong waterproof properties is particularly important, while in cold areas,

performance against low temperatures and cracking is crucial. This results in differences in material selection and construction plans for

roof synthetic underlayment across different regions.

In some specialized applications, the function of roof synthetic underlayment goes beyond protection and separation; it may also integrate

with other building systems. For example, in some green buildings, the roof underlayment may be used in combination with solar panels or

green roof systems, providing additional thermal insulation or energy recovery functions. This trend of multifunctional integration broadens

the use of roof synthetic underlayment and makes it an integral part of overall building design.

Overall, roof synthetic underlayment is not just a simple protective layer for the roof. Its role in building construction is becoming

increasingly important, encompassing durability, environmental friendliness, functionality, and other aspects. With technological

advancements and changing market demands, the development of roof synthetic underlayment is bound to bring more innovation

and breakthroughs to the construction industry.

2025-04-08

DETAIL

MOUNTAIN BIGFOOT BARRIER Redefines the Standard for Waterproof Roofing Underlayments

Waterproof. Weatherproof. Worry-free.

In roofing systems, moisture is the biggest hidden threat. Leaks, rot, and mold often begin with the smallest traces

of water infiltration. MOUNTAIN BIGFOOT BARRIER utilizes advanced waterproofing technology to create a

high-performance protective shield, completely sealing out moisture before it ever reaches the roof deck.

Key Waterproofing Highlights:

Advanced Drainage Structure – Effectively blocks moisture and performs in heavy rain, snow, and complex weather conditions

Seam-Sealing Technology – Works with cap nails and adhesives to form a tightly sealed, leak-resistant barrier

180-Day UV Protection – Maintains waterproof integrity even under prolonged sun exposure during extended construction

No Buckling or Warping – Remains flat and stable in high-humidity environments

Steep-Slope Ready – Designed for compatibility with both residential and commercial roof types

Trusted Protection, Proven Performance

MOUNTAIN BIGFOOT BARRIER has been field-tested across extreme environments—from snow-covered

mountain towns to wind-driven coastal regions. Its superior waterproofing ensures roofing systems stay

dry, secure, and long-lasting during both installation and years of use.

Built for Professional Performance

For contractors and builders, a high-quality roof starts from the bottom up. With fast installation, exceptional

waterproofing, and broad material compatibility, MOUNTAIN BIGFOOT BARRIER helps teams reduce rework,

protect structures, and increase efficiency—all while boosting customer satisfaction.

2025-04-08

DETAIL

Roof Synthetic Underlayment's Environmental Adaptability: Confronting Extreme Weather Challenges

The design and application of roof synthetic underlayment is not just for waterproofing; its environmental adaptability determines whether

it can maintain long-term performance under extreme climate conditions. In the context of global climate change, roofing materials are

facing increasing challenges, especially in variable and extreme weather conditions, making the performance of roof synthetic underlayment

a crucial factor.

1. Adapting to High-Temperature Environments

During hot summer months, roofs are often subjected to intense heat radiation, particularly in tropical and subtropical regions, where the

extreme temperature fluctuations can have significant impacts on traditional materials. Synthetic underlayment, particularly TPO (

Thermoplastic Polyolefin) and PVC (Polyvinyl Chloride) materials, excels with its excellent heat resistance, maintaining stability even in

high-temperature environments.

These materials offer high thermal stability and can withstand prolonged exposure to high temperatures without deforming or losing

their original strength. Especially during scorching summers, synthetic underlayment effectively resists expansion caused by heat,

preventing structural issues resulting from material swelling or softening.

2. Dealing with Extremely Cold Environments

For buildings in cold climates, roofing materials must contend with low temperatures and frost. Traditional roofing underlayment materials

may become brittle, lose their elasticity, or even crack in extremely cold conditions. However, synthetic underlayment demonstrates excellent

low-temperature flexibility. For example, PVC and TPO materials retain their flexibility even in cold weather, unlike traditional materials that

may become brittle.

Additionally, synthetic underlayment maintains a certain level of elasticity in cold environments, which is particularly important for roofs

in northern or colder regions. Even during snow-covered winters, they adapt to temperature changes, preventing damage from the

contraction and expansion of the roof.

3. Waterproofing and Humid Climates

In rainy climates, the waterproofing ability of roof underlayment is critical. This is especially true in tropical areas or coastal cities, where

heavy rainfall and high humidity are common. Synthetic underlayment materials like PVC and TPO offer excellent waterproofing properties.

Their non-porous structure effectively prevents water penetration, ensuring that the underlying roof structure remains dry and secure.

In contrast, traditional materials may suffer from water penetration in high-humidity environments, leading to mold, rot, or rust. Due to its

high resistance to moisture, synthetic underlayment avoids such issues, adapting to humid environments while maintaining long-term

waterproof performance.

4. UV Resistance and Durability

UV rays are a significant factor in determining the lifespan of roofing materials, particularly in areas with intense sunlight. Prolonged

exposure to UV radiation can cause roofing materials to age, become brittle, or crack. However, synthetic underlayment materials like

TPO and PVC are manufactured with UV-resistant additives, ensuring they maintain a long service life even in high-intensity UV

environments.

These materials' aging resistance makes them perform exceptionally well under solar radiation, reducing UV damage and extending the

lifespan of the roof system. Moreover, synthetic materials' UV resistance ensures that they will not fade or crack like some traditional

materials.

5. Wind Resistance and Extreme Weather

For roofs in windy regions, strong winds and heavy rainfall are common causes of roof damage. Roof synthetic underlayment, particularly

those made from high-strength polymer materials, effectively resists strong winds. These materials' strength and flexibility allow them to

withstand the pressure from high winds, preventing tearing or damage during storms.

For example, TPO and PVC materials remain securely fixed even under high wind speeds. In extreme weather conditions such as hurricanes,

they can withstand the force of the wind, reducing the risk of roof damage.

Conclusion

The environmental adaptability of roof synthetic underlayment determines its performance in different climate conditions. Whether in high

temperatures, low temperatures, humid conditions, or intense UV radiation, synthetic underlayment effectively addresses these

environmental challenges and provides long-term protective functionality. Therefore, roof synthetic underlayment not only meets

everyday usage requirements but also maintains stability in extreme weather conditions, making it an essential component of modern

building roofing systems.

2025-04-07

DETAIL

MOUNTAIN BIGFOOT BARRIER: Built for Extreme Conditions

MOUNTAIN BIGFOOT BARRIER is a high-performance roof underlayment engineered to deliver outstanding protection in the harshest

climates and most challenging job site environments. It’s the ideal choice for contractors, developers, and high-end residential projects.

Field-tested across the United States, MOUNTAIN BIGFOOT BARRIER offers exceptional waterproofing, tear resistance, and UV durability.

Whether exposed to high altitudes, strong winds, freezing temperatures, or prolonged sun exposure, it performs with consistent reliability.

“This product is as tough as its name — and exactly what our customers have been asking for,” said the Product Director at Mountain

Materials. “From alpine builds to cold-weather zones and long-construction timelines, MOUNTAIN BIGFOOT BARRIER delivers dependable

protection and stands up to nature’s toughest conditions.”

Engineered for Extreme Jobsite Conditions – Key Features:

High-strength synthetic construction – 5x the tear resistance of traditional felt

Slip-resistant surface – improved safety for steep-slope roof applications

UV resistant for up to 180 days – ideal for extended project timelines

Cold-crack resistant to -40°F (-40°C) – stays flexible in freezing temperatures

Broad material compatibility – works with asphalt shingles, metal roofing, clay tile, and more

MOUNTAIN BIGFOOT BARRIER provides a strong foundation for modern roofing systems—helping reduce callbacks, extend roof life, and

improve installation efficiency. Whether it’s a mountain cabin or a coastal home, it delivers powerful protection from the elements.

2025-04-07

DETAIL

BIGFOOT 15

Learn More

BIGFOOT 15

Learn More

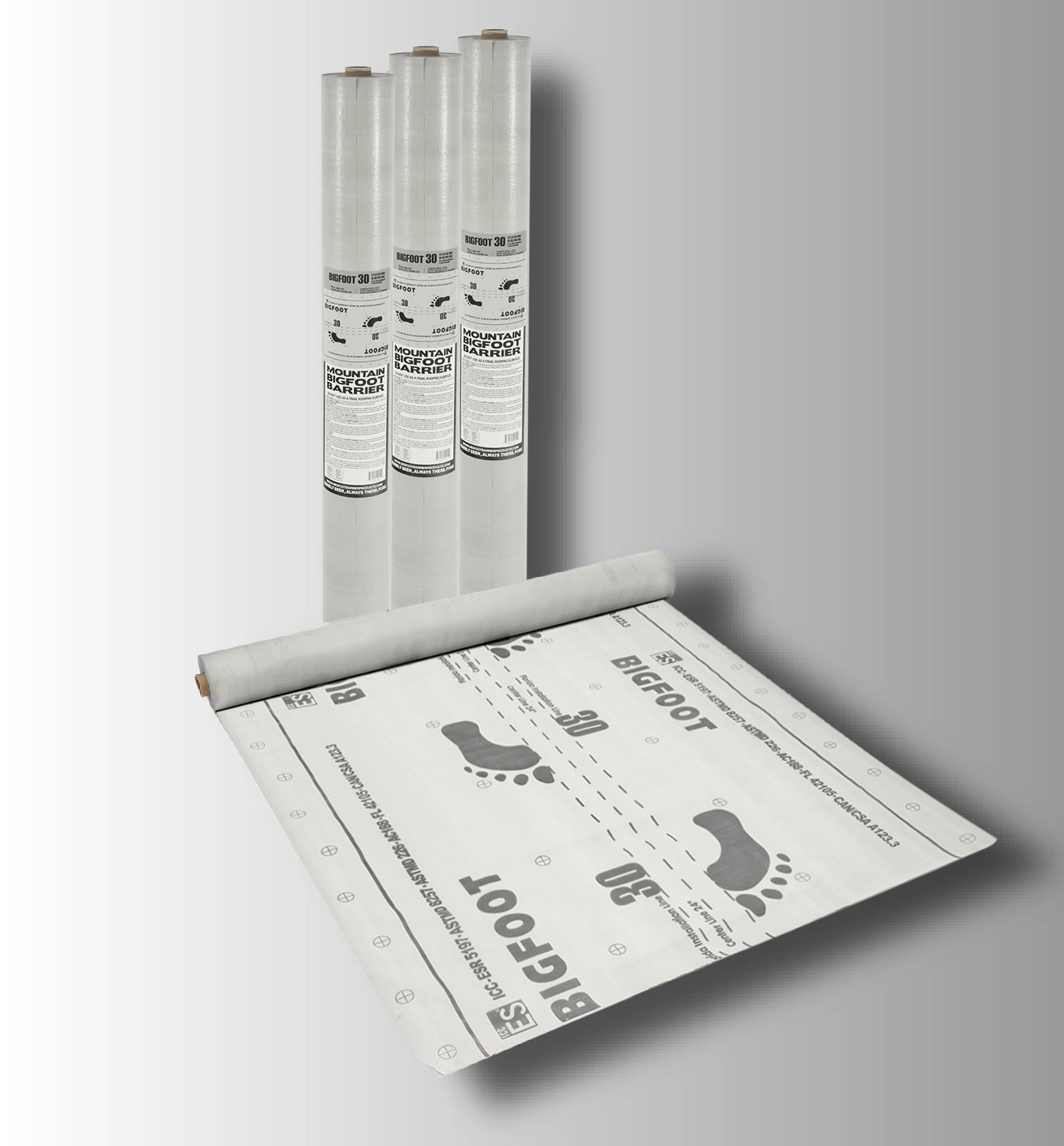

BIGFOOT 30

Learn More

BIGFOOT 30

Learn More

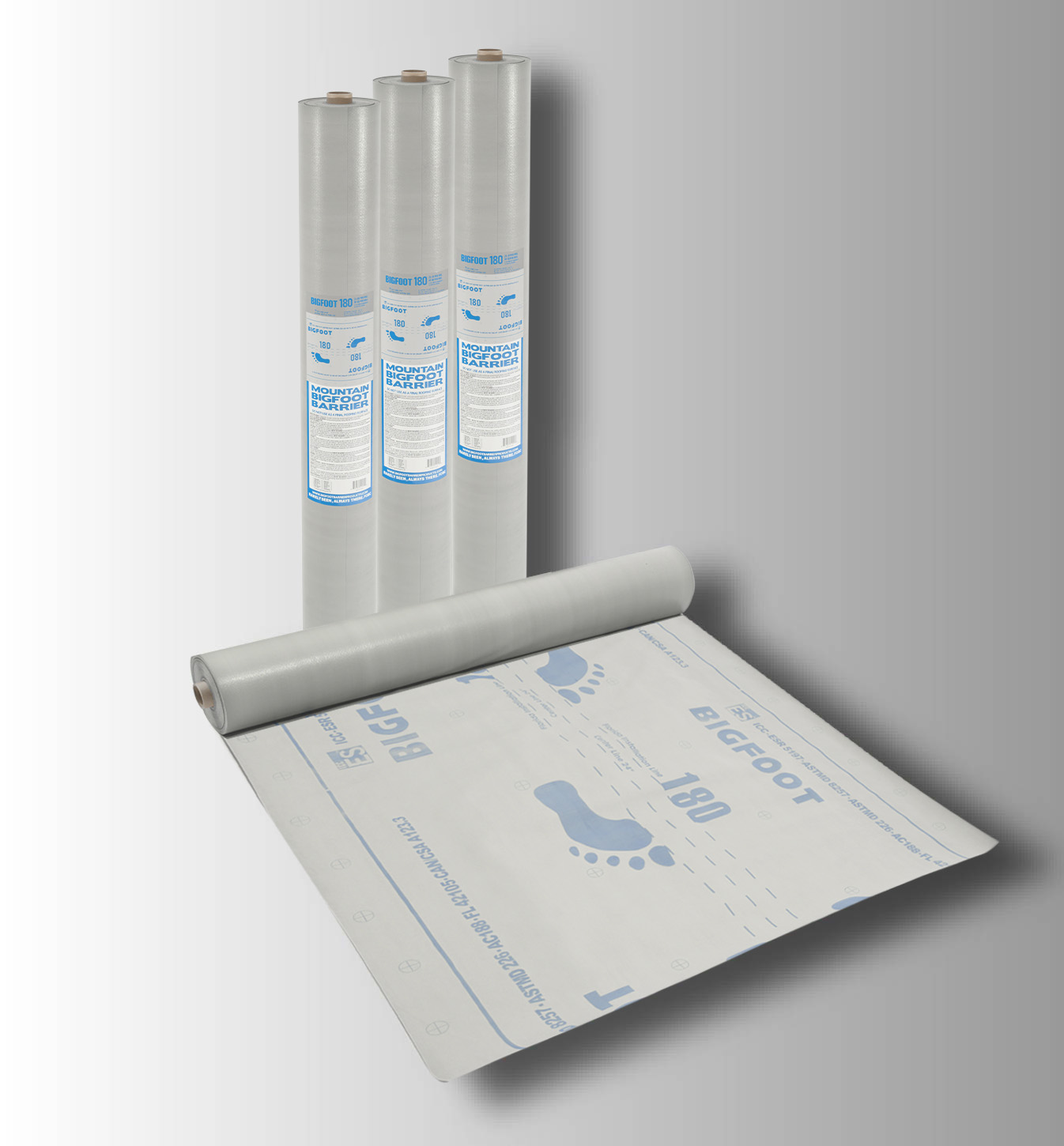

BIGFOOT 180

Learn More

BIGFOOT 180

Learn More

BIGFOOT HD

Learn More

BIGFOOT HD

Learn More

BIGFOOT 15

BIGFOOT 15

BIGFOOT 30

BIGFOOT 30

BIGFOOT 180

BIGFOOT 180

BIGFOOT HD

BIGFOOT HD

Back

Back