Key Functions and Applications of Roofing Synthetic Underlayment

Roofing synthetic underlayment is a critical material used in building roof systems, typically made from synthetic materials such as

polyethylene, PVC, and others. As part of the roof structure, its primary function is to enhance the roof's overall performance, particularly

in terms of waterproofing and thermal insulation. With the advancement of building technologies and increasing demands for energy

efficiency, synthetic underlayment has become an essential component in modern architectural design.

Functions of Roofing Synthetic Underlayment

As an important layer in roofing systems, the key functions of synthetic underlayment are as follows:

Waterproof Protection: One of the core functions of roofing synthetic underlayment is waterproofing. It effectively prevents water

penetration, protecting the roof structure from rain and water accumulation. This function is particularly important in extreme weather

conditions, where the waterproof layer becomes crucial. The synthetic underlayment acts as an auxiliary material to enhance the roof's

waterproof performance.

Thermal Insulation: Synthetic underlayment often has good thermal insulation properties, helping the roof system maintain cooler

temperatures in the summer and retain warmth in the winter. By effectively blocking the transmission of external temperatures, the

underlayment reduces the load on air conditioning and heating systems, improving indoor comfort and saving energy.

Extending Roof Lifespan: By reducing the direct impact of external factors such as UV rays, wind, and rain, synthetic underlayment helps

extend the roof’s lifespan. It provides an additional protective layer, preventing premature wear and aging of roof materials.

Enhancing Structural Stability: The synthetic underlayment's role in the roofing system is not limited to waterproofing and insulation.

It also provides additional structural support for the roof, preventing deformation or damage caused by external forces.

Installation and Maintenance of Roofing Synthetic Underlayment

The installation of synthetic underlayment requires careful planning to align with the roof's structural design. Typically, the underlayment

is installed between the waterproof layer and roofing materials to ensure it provides both waterproofing and insulation functions. During

installation, workers must ensure that the underlayment material is tightly connected with other roof components to prevent leaks or heat

loss.

In terms of maintenance, synthetic underlayment should be regularly inspected, especially after heavy rainfall, snow, or prolonged exposure

to intense sunlight, to ensure it remains intact. Although synthetic underlayment is highly durable, any signs of damage or aging should be

addressed promptly to maintain the overall performance of the roof system.

Future Development of Roofing Synthetic Underlayment

As the construction industry increasingly focuses on energy efficiency and sustainability, the technology behind roofing synthetic

underlayment is continuously evolving. In the future, more innovative synthetic materials may be developed to provide even better

thermal insulation, waterproofing, and extended lifespans. Additionally, with the promotion of green building practices, synthetic

underlayment will likely be integrated with ecological roofing systems, rainwater harvesting systems, and other sustainable building

solutions to further enhance environmental performance.

In conclusion, roofing synthetic underlayment is not only an indispensable component of modern roofing systems but also an important

means of improving the overall performance of buildings and achieving energy-efficient and environmentally-friendly goals. As technology

advances and market demand increases, its applications will become even more widespread, making it a vital part of architectural design.

2025-03-25

DETAIL

Synthetic Roofing Underlayment – Exceptional Waterproofing Performance Upgraded

As the construction industry increasingly demands superior roofing waterproofing solutions, synthetic roofing

underlayment has become a standard choice for new builds and renovation projects. With its unique materials

and innovative technologies, synthetic roofing underlayment excels in waterproofing performance, providing a

reliable barrier against harsh weather conditions.

Non-Absorbent Material Properties:

Unlike traditional asphalt roofing underlayment, synthetic roofing underlayment is typically made from hydrophobic

polymers such as polypropylene (PP) or polyethylene (PE). These materials exhibit a very low affinity for water, maintaining

structural stability even under wet or rainy conditions. In contrast to traditional asphalt materials, synthetic underlayment

does not absorb water, soften, or delaminate in damp environments, ensuring the roofing structure remains strong and intact.

Seamless, Continuous Waterproof Layer:

To further enhance waterproofing performance, many high-quality synthetic roofing underlayments utilize multi-layer

co-extrusion or lamination techniques to tightly bond the waterproof membrane to the backing layer. This creates a

highly continuous and uniform waterproof barrier, similar to a solid "shield," which significantly reduces potential leakage

points. The innovative technology behind synthetic roofing underlayment undoubtedly offers buildings more stable and

reliable protection.

Proven Waterproofing Tests:

Top-quality synthetic roofing underlayment undergoes rigorous laboratory testing (such as ASTM D4869 or

ICC-ES requirements) to validate its waterproofing capabilities. These underlayments can withstand heavy

rainfall or snowmelt conditions without leakage, even after hours or days of water pressure testing, ensuring

that roofs stay dry and secure during extreme weather events.

As technology continues to evolve, synthetic roofing underlayment, with its exceptional waterproofing and

durability, is gradually becoming the industry standard, and it is expected to be a key solution for global roofing

waterproofing needs in the coming years.

2025-03-25

DETAIL

The New Darling of the Construction Industry, Driving the Green Building Revolution

As global attention on environmental protection and energy efficiency continues to rise, the construction industry is undergoing a

transformation centered around sustainability. In this revolution, synthetic roof underlayment materials, as an innovative building product,

are gradually emerging and becoming the core of new-generation roofing solutions.

The Rise of Synthetic Roof Underlayment

Synthetic roof underlayment, typically made from materials such as polyvinyl chloride (PVC), thermoplastic olefin (TPO), and ethylene

propylene diene monomer (EPDM), has become an ideal alternative to traditional roofing materials due to its excellent weather resistance,

waterproofing, and strong UV protection capabilities. Globally, the demand for synthetic roof underlayment is rapidly increasing, particularly

in regions where energy efficiency is a key focus.

Environmental Friendliness and Sustainability: Core Advantages of Synthetic Roof Underlayment

Synthetic roof underlayment not only offers exceptional performance in terms of functionality but also has environmental benefits, which

are a major driving force behind its rapid growth. First, synthetic materials tend to have a longer lifespan, reducing the frequency of

replacements and thus minimizing construction waste. Additionally, synthetic roof underlayment is often made from recyclable materials,

making it easier to recycle and reuse at the end of a building's life cycle. With the gradual implementation of global green building

standards, synthetic roof underlayment has become a key material for obtaining LEED (Leadership in Energy and Environmental Design)

certification and other environmental certifications.

Technological Innovation Driving Performance Enhancement

The technology behind synthetic roof underlayment continues to evolve to meet more stringent building standards and diverse

climate conditions. For example, TPO underlayment, with its excellent heat-reflective properties, helps reduce roof surface heat island

effects, lowering the cooling load of buildings and improving indoor temperature control. Additionally, PVC roofing underlayment offers

significant advantages in UV resistance and chemical corrosion protection, making it ideal for buildings in extreme climates.

Currently, more and more builders are adopting synthetic roof underlayment as an effective solution to improve building energy efficiency

and extend roof lifespan. Synthetic roof underlayment not only effectively seals out moisture but also enhances the thermal insulation of

roofs, contributing to more energy-efficient building designs.

Surging Market Demand and Bright Prospects for Synthetic Roof Underlayment

According to industry reports, the global synthetic roof underlayment market is expected to expand at a compound annual growth

rate (CAGR) of approximately 8% over the next five years. Particularly in regions such as the United States, Europe, and parts of Asia,

the demand for synthetic roof underlayment is growing as the construction industry increasingly seeks green materials. Whether in

commercial buildings, industrial facilities, or residential projects, the use of synthetic roof underlayment is becoming an indispensable

part of modern architectural design.

Many roofing contractors and construction companies have expressed that the use of synthetic roof underlayment has helped them

reduce roof maintenance costs while enhancing overall building performance. Moreover, as more environmental regulations are enacted,

buildings using synthetic roof underlayment are increasingly eligible for government green building subsidies and policy support.

Challenges and Future Outlook

Although the prospects for synthetic roof underlayment are highly promising, there are still some challenges. For instance, some

consumers and builders remain skeptical about the durability and environmental impact of synthetic materials, especially in markets

where traditional roofing materials still dominate. However, as technology continues to improve and material costs decrease, these

concerns are expected to be addressed, making synthetic roof underlayment more accessible and widely adopted.

Industry experts predict that with advancements in manufacturing processes and the push from environmental regulations, synthetic

roof underlayment will become a mainstream choice in the construction industry over the next few years. It will not only continue to

drive innovation in building materials but also contribute positively to global sustainability efforts.

Conclusion

The rise of synthetic roof underlayment marks a significant step toward a more environmentally friendly and energy-efficient

construction industry. With its exceptional performance and sustainability, synthetic roof underlayment will play an increasingly

important role in future construction projects. As technology continues to evolve and market demand grows, synthetic roof

underlayment is undoubtedly poised to become a vital component of modern buildings, driving the green building revolution

forward.

2025-03-24

DETAIL

Synthetic Roof Underlayment: Highlighting the Overall Economic Value and Lifecycle Cost Advantages

Recently, with the increasing attention paid by the construction industry to the performance and cost-effectiveness

of materials, synthetic roof underlayment has gradually become the focus of the market due to its unique overall

economic value and lifecycle cost advantages.

Although the initial investment in synthetic roof underlayment may be slightly higher than that of traditional asphalt

felt, it demonstrates extremely high cost-effectiveness during long-term use. Thanks to its excellent durability, it can

effectively reduce the risks of leakage and damage, greatly reducing the lifecycle cost of the roof. This means that long

-term repair costs and internal damage expenses caused by water penetration will be significantly reduced.

In terms of reducing repair and maintenance costs, synthetic roof underlayment performs remarkably well. It can

significantly reduce the occurrence of leakage, thereby avoiding damage to the interior decoration, insulation

layer, and structural components, achieving an almost "zero-maintenance" ideal state and saving a large amount

of repeated labor and material costs for property owners.

In addition, synthetic roof underlayment also plays an important role in enhancing property value and living comfort.

A roof system using this high-quality underlayment can significantly increase the value and attractiveness of the property.

For developers, this is a powerful means to enhance the competitiveness of their projects; for homeowners, synthetic

roof underlayment can not only provide solid protection for the building structure but also create a more comfortable

and reliable living environment for residents.

Industry experts said that with the continuous progress of technology and the improvement of market awareness,

synthetic roof underlayment is expected to occupy a larger share in the future construction market, bringing a dual

improvement in economy and performance to more construction projects.

2025-03-24

DETAIL

An Emerging Trend in the Construction Industry

With the continuous advancement of construction technology and the increasing demand for durability and environmental sustainability

in buildings, synthetic roof underlayment has become an essential material in modern construction. As an alternative to traditional asphalt

underlayment, synthetic underlayment is rapidly gaining popularity and playing an increasingly important role in roofing projects.

Origin and Development of Synthetic Roof Underlayment

Synthetic roof underlayment was initially developed to address the shortcomings of traditional paper-based underlayment in terms of

waterproofing and durability. Early roofing underlayment was primarily made from asphalt and paper, which provided some level of

waterproofing but fell short in terms of durability and resistance to environmental conditions. These materials were prone to moisture

damage, decay, and could even lead to roof leaks. As the construction industry demanded higher-performing materials, synthetic

alternatives became more prevalent. Today, synthetic roof underlayment is widely used in various construction projects, becoming a

critical component of modern roofing systems due to its superior performance and diverse options.

Applications of Synthetic Roof Underlayment

The applications of synthetic roof underlayment are vast, ranging from residential homes to commercial buildings. It is installed beneath

the roofing shingles, providing a protective layer that shields the roof structure from water damage and extends the lifespan of the roof.

In new buildings, synthetic underlayment provides an extra layer of protection, ensuring the roof can withstand harsh weather conditions.

In roof renovations, it helps enhance the waterproofing of the structure, reducing the risk of leaks.

In particular, synthetic underlayment is highly beneficial in regions with high humidity or frequent rainfall, where it acts as a reliable

protective layer to prevent water infiltration and roof decay. Additionally, in extreme weather conditions such as strong winds or heavy

rain, the tear-resistant properties of synthetic underlayment provide extra protection for the roof.

Technological Advancements and Innovation Driving Development

The continued evolution of synthetic underlayment is driven by innovations in material science and manufacturing processes. Modern

synthetic underlayments are made from a variety of high-performance materials, including polypropylene, polyethylene, and other

synthetic fibers. These materials offer excellent waterproofing, UV resistance, and high-temperature tolerance, while also providing

increased mechanical strength, ensuring the underlayment performs well under harsh weather conditions.

In addition to material innovations, the production processes for synthetic underlayment have also improved. More manufacturers are

employing advanced coating technologies, making the surface of the underlayment smoother and more even, which further enhances

its waterproofing capabilities. Moreover, modern synthetic underlayment has been optimized for weight and flexibility, making it easier

and more efficient for contractors to install.

Industry Outlook and Future Prospects

With the growing emphasis on green building and sustainability, synthetic roof underlayment, as an eco-friendly and durable building

material, is expected to see continued demand. The construction industry’s ongoing need for higher-performing materials will further

drive the development of synthetic underlayment technologies. In the future, synthetic underlayment may find applications in more areas,

becoming an indispensable part of construction materials.

Whether in the rooftops of high-rise buildings or residential homes, synthetic roof underlayment will provide more reliable protection

for buildings. In the future, it will not only serve as a protective layer but also become a key component in the creation of green,

sustainable, and long-lasting buildings, driving the construction industry toward a more sustainable future.

2025-03-22

DETAIL

Synthetic Roof Underlayment Demonstrates Excellent Compatibility, Helping to Enhance Roof Performance

Recently, the outstanding performance of synthetic roof underlayment in terms of compatibility with various

roofing materials has received much attention. Its multifunctional characteristics in roof covering applications

have brought new vitality to the construction industry.

Remarkable Compatibility Advantages

Synthetic roof underlayment shows impressive compatibility when dealing with various types of roof coverings.

Whether it is common asphalt shingles, metal sheets (steel, aluminum, copper), clay tiles, concrete tiles, wood

shingles, or composite panels, synthetic roof underlayment can perfectly match with them. Its specially treated

surface not only has no adverse effects on the adhesion of roofing materials but also does not interfere with the

thermal expansion process of the materials. On the contrary, it can enhance the durability and stability of roofing

materials, laying a solid foundation for the long-term reliable operation of the roof system.

Contributing to Extending Service Life

Synthetic roof underlayment plays a crucial role in extending the service life of roof coverings. By providing a dry

and stable base, it effectively protects the upper materials from water damage and deformation problems. For

example, when synthetic roof underlayment is laid under a metal roof, it can inhibit corrosion at the bottom and

extend the service life of the metal roof. When used under asphalt shingles, it can significantly reduce the risk of

asphalt compound leakage caused by overheating, ensuring the stable performance of asphalt shingles. This

characteristic makes synthetic roof underlayment an ideal choice for enhancing the overall performance of the roof

and reducing maintenance costs.

With the continuous improvement of the construction industry's requirements for roof quality and durability,

synthetic roof underlayment, with its excellent compatibility and protective effect on roof coverings, is expected

to be more widely applied in future construction projects.

2025-03-22

DETAIL

Synthetic Roof Underlayment: A New Choice for Enhancing Roof Performance

As the construction industry continues to seek materials that enhance roof performance, synthetic roof underlayment has become an

increasingly popular solution. This innovative material is widely used in roofing systems to provide improved waterproofing, insulation,

and durability, while also extending the lifespan of the roof. This article delves into the functions and applications of synthetic roof

underlayment and its significant impact on building structures.

Functions of Synthetic Roof Underlayment

Synthetic roof underlayment is a layer of synthetic material installed beneath roofing tiles, primarily designed to enhance the protection

of roofing systems. It is typically made from polymers, fibers, or other synthetic materials, designed to perform well in various climate and

environmental conditions. Unlike traditional asphalt-based underlayment, synthetic underlayment utilizes modern technological materials,

offering a more comprehensive performance to enhance the overall roof structure.

Waterproofing Function

One of the key functions of synthetic roof underlayment is to provide an effective waterproof barrier. In environments with heavy rain,

snow, or high humidity, the underlayment prevents water from penetrating into the roof, thus protecting the roof structure from damage

or corrosion. Particularly when the roof tiles or other outer layers are damaged, synthetic underlayment continues to offer protection,

ensuring the building’s safety.

Insulation Function

Synthetic underlayment also offers excellent insulation properties. In the summer, it helps reduce the heat transfer from direct sunlight,

keeping the interior cool. In the winter, it prevents heat from escaping, improving the overall comfort of the indoor environment. This

function is crucial in improving the energy efficiency of a building, especially in areas with fluctuating climates, where synthetic

underlayment becomes a key material for regulating roof temperatures.

UV Resistance and Durability

The durability of synthetic underlayment is another notable feature. It can withstand prolonged exposure to ultraviolet (UV) radiation

without deteriorating. Its special UV-resistant design ensures that the underlayment remains stable even after long-term exposure to

outdoor conditions, thereby extending the overall lifespan of the roofing system.

Installation and Maintenance of Synthetic Roof Underlayment

When installing synthetic roof underlayment, it is typically laid over the base of the roof, covering the entire surface. Synthetic

underlayment is compatible with various roofing materials, such as tiles or metal panels, and the installation process is relatively simple

and efficient. Its lightweight nature makes the construction process faster, reducing labor and time costs.

In terms of maintenance, synthetic underlayment requires minimal upkeep due to its durability and UV resistance. Regular inspections

to check for external damage and ensuring the underlayment remains intact are generally sufficient. In most cases, it does not need to

be replaced or repaired frequently.

Conclusion

Synthetic roof underlayment is not just a simple waterproofing material; it provides highly effective functional support for modern

buildings, especially in terms of waterproofing, insulation, and durability. As the construction industry demands higher performance

materials, synthetic underlayment has become an essential component of roofing systems. Its application not only improves the safety

and comfort of buildings but also contributes to enhanced sustainability and energy efficiency in modern architecture.

2025-03-21

DETAIL

Synthetic Roofing Materials: Significant Environmental and Health Benefits

Recently, with the increasing attention paid to environmental protection and health in the construction industry,

a new type of synthetic roofing material has received widespread attention due to its excellent environmental and

health benefits.

Reducing VOC Emissions to Protect the Environment and Health

This synthetic material does not use a large amount of asphalt components during the production process. This characteristic

ensures that it will not release a strong petroleum odor or a large amount of volatile organic compounds (VOCs) during use.

This advantage not only creates a healthier working environment for installers during the construction process but also protects

occupants from the harm of VOCs, greatly reducing the negative impact on the environment.

Recyclability to Boost Green Building Development

In addition, this synthetic roof underlayment material is recyclable at the end of its service life. Relevant data shows that

its recycling can effectively reduce the generation of construction waste and resource consumption. This characteristic is

highly consistent with the current concept of green buildings. For construction projects that pursue LEED certification and

the goal of sustainable development, it is undoubtedly an ideal choice. Experts in the construction industry said that the

wide application of such materials is expected to promote the entire construction industry to develop in a more environmentally

friendly and healthy direction.

2025-03-21

DETAIL

Application and Development of Roof Synthetic Underlayment

Roof synthetic underlayment, a new type of building material, has gained increasing popularity in the construction industry in recent

years. Its role in roofing systems goes beyond waterproofing; it also enhances the durability, weather resistance, and energy efficiency

of roofs. As the construction industry places more emphasis on green buildings and environmentally friendly materials, roof synthetic

underlayment has gradually become an essential component in modern architecture.

History and Development of Roof Synthetic Underlayment

The origin of roof synthetic underlayment can be traced back to the 1960s. The earliest synthetic roofing underlayment materials were

primarily made from rubber or polyvinyl chloride (PVC), designed to increase roof waterproofing and durability. With continuous

advancements in building material technology, especially the application of synthetic polymers, the types and performance of roof

synthetic underlayment materials have significantly improved.

In the 1990s, roof synthetic underlayment materials began to gain wider adoption in Europe and the United States, particularly in

commercial buildings and industrial facilities. Today, as environmental awareness has grown, roof synthetic underlayment has expanded

into residential buildings and is widely used in green building projects, becoming an important element in modern architectural design.

Practical Applications of Roof Synthetic Underlayment

Residential Buildings

In residential buildings, roof synthetic underlayment is primarily used for waterproofing and insulation. Particularly in areas with

heavy rainfall and humidity, synthetic underlayment effectively prevents water infiltration and roof leaks. Additionally, it helps

provide insulation during the summer, reducing air conditioning energy consumption and improving indoor comfort. Roof

synthetic underlayment is also often integrated with green roofing systems to support and protect plants.

Commercial Buildings and Industrial Facilities

For commercial buildings and industrial facilities, the durability and weather resistance of roof synthetic underlayment are especially

important. These buildings are often exposed to harsh environmental conditions such as strong ultraviolet radiation, high temperatures,

strong winds, and chemical corrosion. Roof synthetic underlayment effectively protects the roof structure from damage caused by

environmental factors. In chemical plants and high-humidity areas, the corrosion resistance and chemical resistance of synthetic

underlayment are particularly beneficial.

Green Roofing Systems

With the rapid pace of urbanization, green roofs have become an important part of urban sustainable development. Roof synthetic

underlayment plays a crucial role in green roofing systems. It provides a solid waterproofing, drainage, and separation layer for the

green roof, ensuring healthy plant growth while protecting the roof structure from water damage. By using synthetic underlayment,

green roofing systems can effectively reduce urban heat island effects and improve the energy efficiency of buildings.

Solar Photovoltaic Systems

Solar photovoltaic systems have become widely used in modern buildings, and roof synthetic underlayment provides a stable support

foundation for solar panels. Synthetic underlayment helps prevent water infiltration into the roof structure, extending both the roof's

and solar panel's lifespan. Due to its ultraviolet resistance and weathering characteristics, roof synthetic underlayment also enhances the

overall performance of solar panels, ensuring they remain effective even under long-term exposure to the elements.

Installation and Maintenance of Roof Synthetic Underlayment

Roof synthetic underlayment installation is typically carried out by professional contractors. The process is relatively simple and does not

require major alterations to the existing roof structure. Depending on the roof’s shape and requirements, the underlayment material can be

adjusted to ensure full coverage of the roof surface. During installation, the underlayment is typically combined with other roofing

components, such as insulation layers, drainage systems, and ventilation systems, to create an efficient roofing protection system.

Compared to traditional roofing materials, roof synthetic underlayment has lower maintenance costs. Its durability and resistance to aging

are strong, and typically only periodic checks for damage, water accumulation, or debris buildup are necessary. To extend the roof's service

life, regular cleaning and inspection are essential, especially in areas with extreme weather or heavy rainfall.

2025-03-20

DETAIL

Synthetic Roof Underlayment: Highlighting Overall Economic Value and Life Cycle Cost Advantages

Recently, with the continuous development of building material technology, synthetic roof underlayment has gradually

emerged in the construction industry. It has demonstrated remarkable advantages in terms of overall economic value

and life cycle costs, attracting widespread attention.

Although the initial cost of synthetic roof underlayment may be slightly higher than that of traditional asphalt felt, it has

outstanding cost-effectiveness in long-term use. Due to its excellent durability, it can effectively reduce the risks of leakage

and damage, significantly reducing the life cycle cost of the roof. In the long run, this not only reduces repair costs but

also avoids the expenses for internal damages caused by water seepage, saving a large amount of money for building

owners.

Meanwhile, synthetic roof underlayment performs exceptionally well in reducing repair and maintenance costs. It

can effectively prevent leakage, thus avoiding damages to the interior decoration, insulation layers, and structural

components, achieving an ideal condition of nearly "zero maintenance" and saving owners the repeated investment

in labor and materials.

From the perspective of property value enhancement, a roof system with high-quality synthetic roof underlayment

can significantly increase the value and attractiveness of the property. For developers, this undoubtedly adds selling

points to the real estate projects. For homeowners, it not only provides better protection for the building structure

but also creates a more comfortable and reliable living environment for residents.

Industry experts stated that with the continuous increase in the market's requirements for the performance of

building materials, synthetic roof underlayment is expected to occupy a larger share in the future construction

market and contribute to the sustainable development of the construction industry.

2025-03-20

DETAIL

A New Material Driving Innovation in Construction

Roof synthetic underlayment, a new type of material in modern building roofing systems, has gradually gained application in recent years.

Made from high-performance synthetic materials, it is commonly used to improve the waterproofing and durability of roofs. Despite its

potential in the market, the promotion of roof synthetic underlayment still faces some challenges.

Growing Market Demand

As the demand for green buildings rises, the market demand for roof synthetic underlayment is steadily increasing. More and more

builders are beginning to recognize its advantages in improving building energy efficiency and extending the lifespan of roofs. However,

many smaller construction companies still prefer traditional roofing materials, making it harder for synthetic underlayment to become

widely adopted.

Technical Development Bottlenecks

Roof synthetic underlayment still faces some technical bottlenecks. There is significant variation in product quality among different brands

in the market, and a lack of unified industry standards creates confusion for consumers and hinders the healthy development of the industry.

Additionally, production processes and material technologies need continuous improvement to enhance product quality and reduce

production costs.

Construction and Maintenance Challenges

Although the installation of roof synthetic underlayment is relatively simple, it still requires professional installation teams. Some

construction workers lack the necessary experience, which could affect the installation results. Moreover, synthetic underlayment requires

regular inspection and maintenance to maintain its long-term performance, and builders and property owners must pay attention to this.

Conclusion

As an emerging material, roof synthetic underlayment has significant potential to improve roofing performance. Although the market and

technical development still face challenges, with the improvement of industry standards and technological advancements, roof synthetic

underlayment is expected to see broader application in the future.

2025-03-19

DETAIL

Synthetic Roof Underlayment: The Lightweight Option Revolutionizing Roof Installation

In the construction industry, synthetic roof underlayment is quietly changing the traditional landscape of roof

construction with its lightweight and efficient installation features.

I. Remarkable Weight and Handling Advantages

Synthetic roof underlayment shows a huge advantage in terms of weight. Depending on the product grade, its

weight generally ranges from 90 to 200 grams per square meter. In sharp contrast, traditional 30 - pound asphalt

felt, when converted, weighs approximately 1.0 - 1.2 kilograms per square meter. Such a significant weight difference

not only greatly reduces transportation costs but also significantly eases the handling difficulty. For construction

workers, the reduction in handling weight effectively reduces fatigue and the risk of injury, providing a strong

guarantee for construction safety.

II. Convenient Cutting and Arrangement Features

The installation process of synthetic roof underlayment is extremely convenient. The membrane material has good

workability. Workers can easily complete the cutting work with just an ordinary utility knife or scissors, without the

need for special tools. This feature enables installation workers to quickly adjust the underlayment according to the

unique shape and size of the roof. Whether it is the complex ridge part or the special skylight area, it can be quickly

adapted, greatly accelerating the installation process and effectively improving construction efficiency.

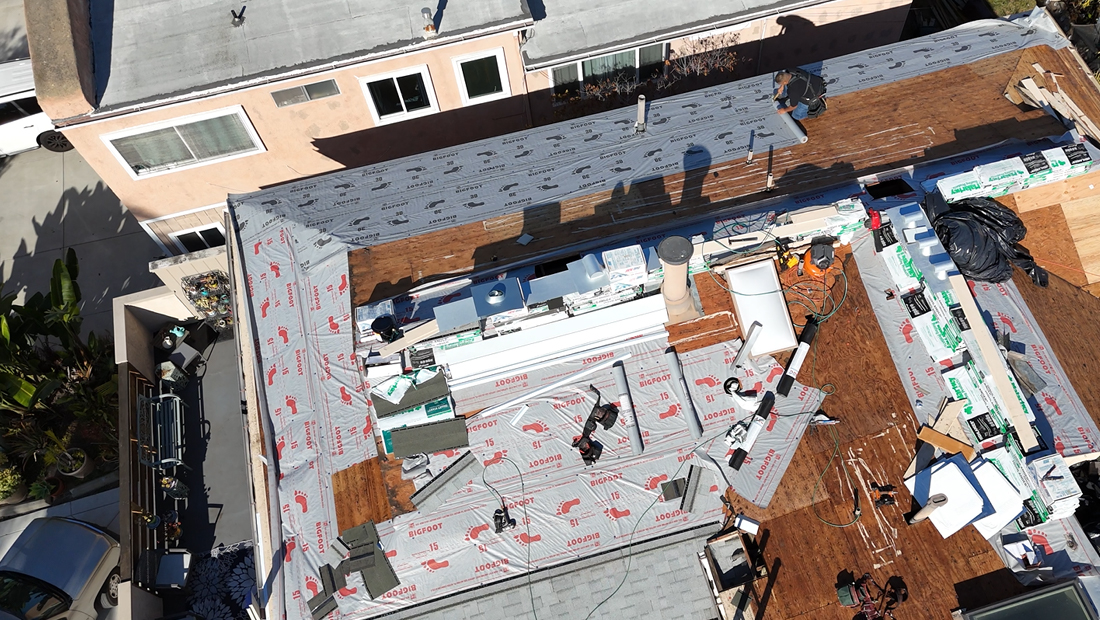

III. Precision Printing Alignment Guides

Some brands of synthetic roof underlayment are carefully printed with alignment lines or grids on the surface. These

printed markings become a powerful assistant for installation workers to operate accurately. Through these guides,

installation workers can layout more accurately, ensuring that the overlap between the underlayments meets the

standards. This not only improves the installation speed but also significantly enhances the overall aesthetics of the

roof after laying.

Synthetic roof underlayment, with its advantages in weight, cutting and arrangement, and precision installation, is

bringing a new and efficient experience to construction, promoting the industry to develop in a safer and more efficient

direction.

2025-03-19

DETAIL

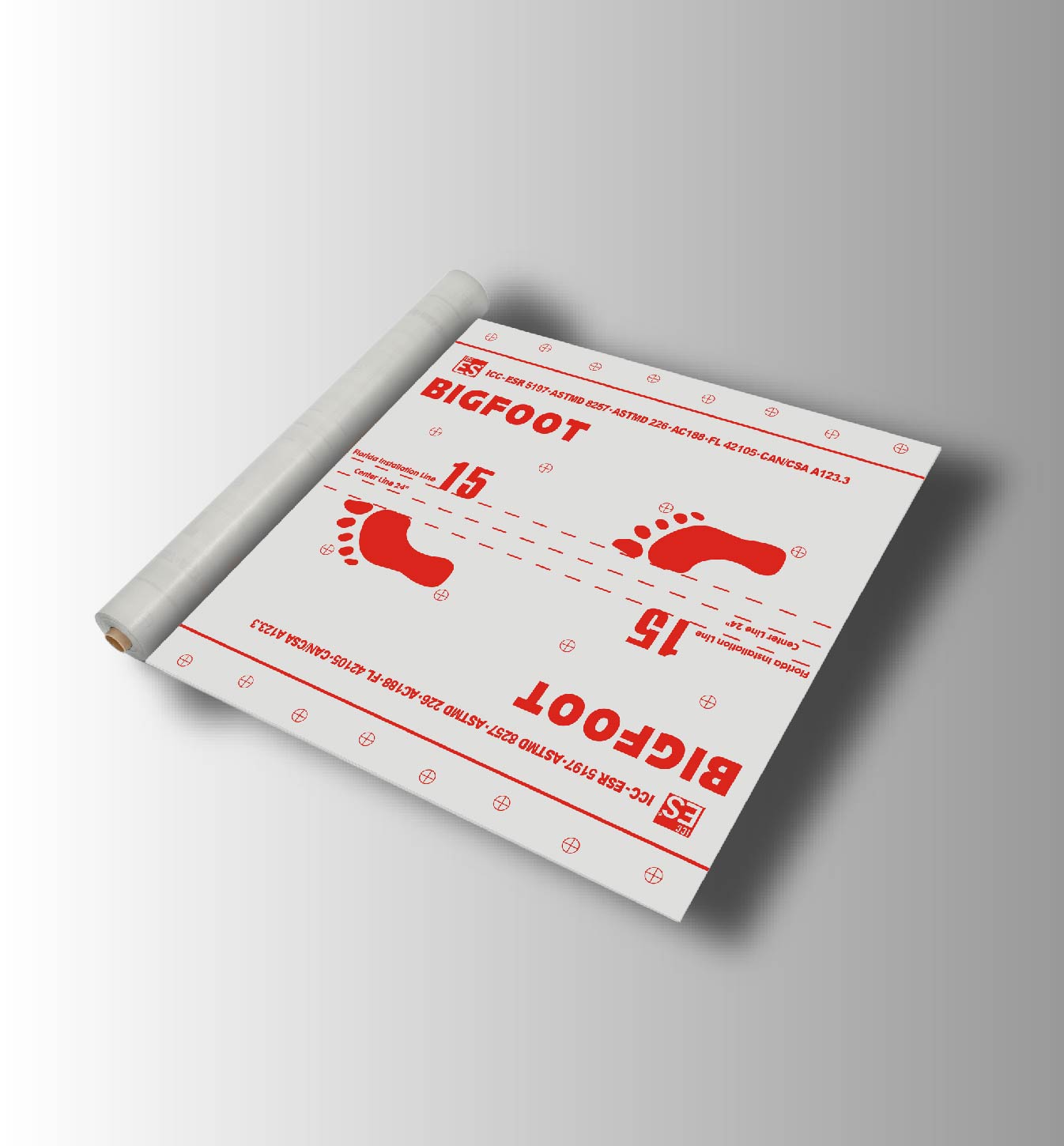

BIGFOOT 15

Learn More

BIGFOOT 15

Learn More

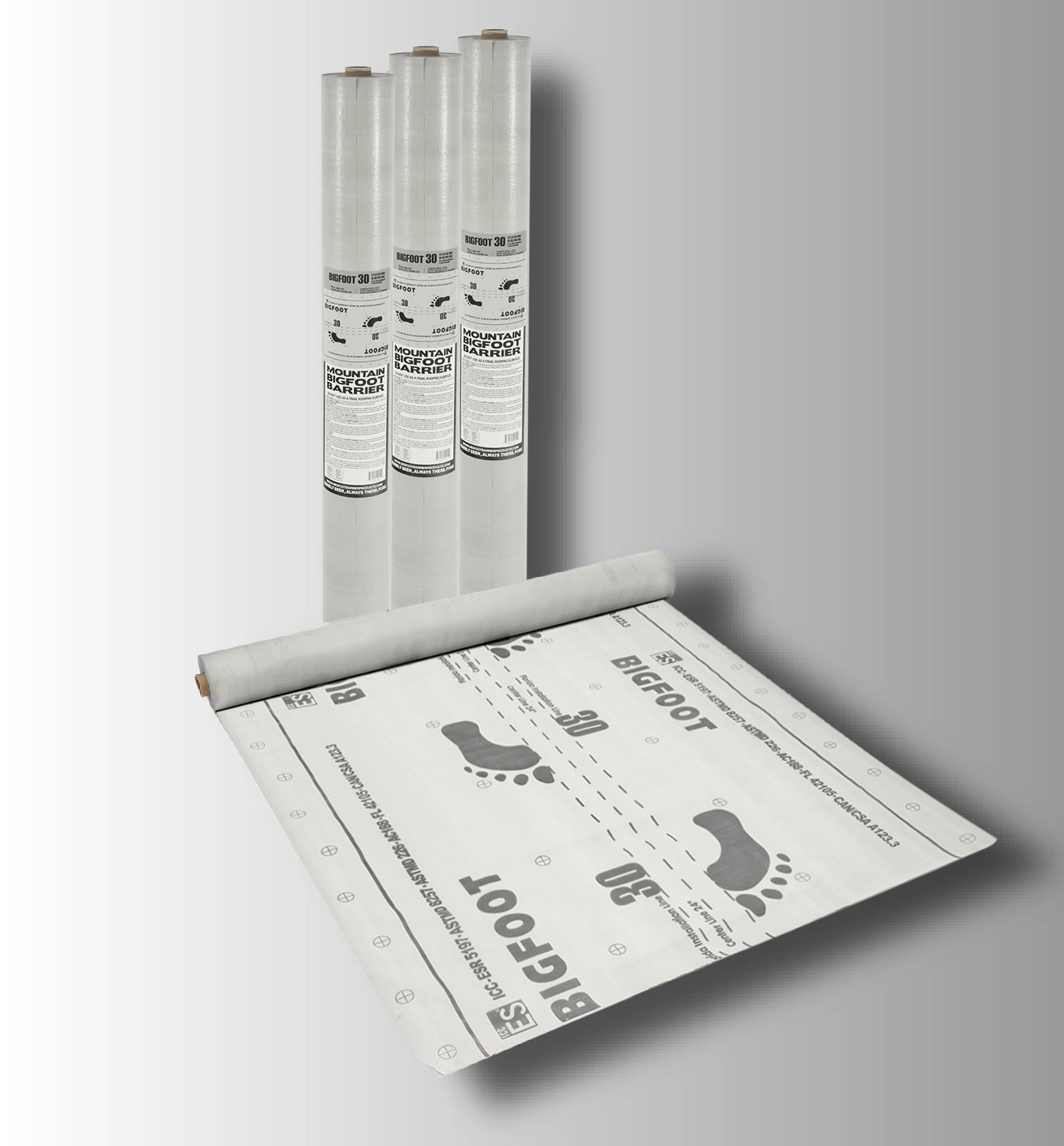

BIGFOOT 30

Learn More

BIGFOOT 30

Learn More

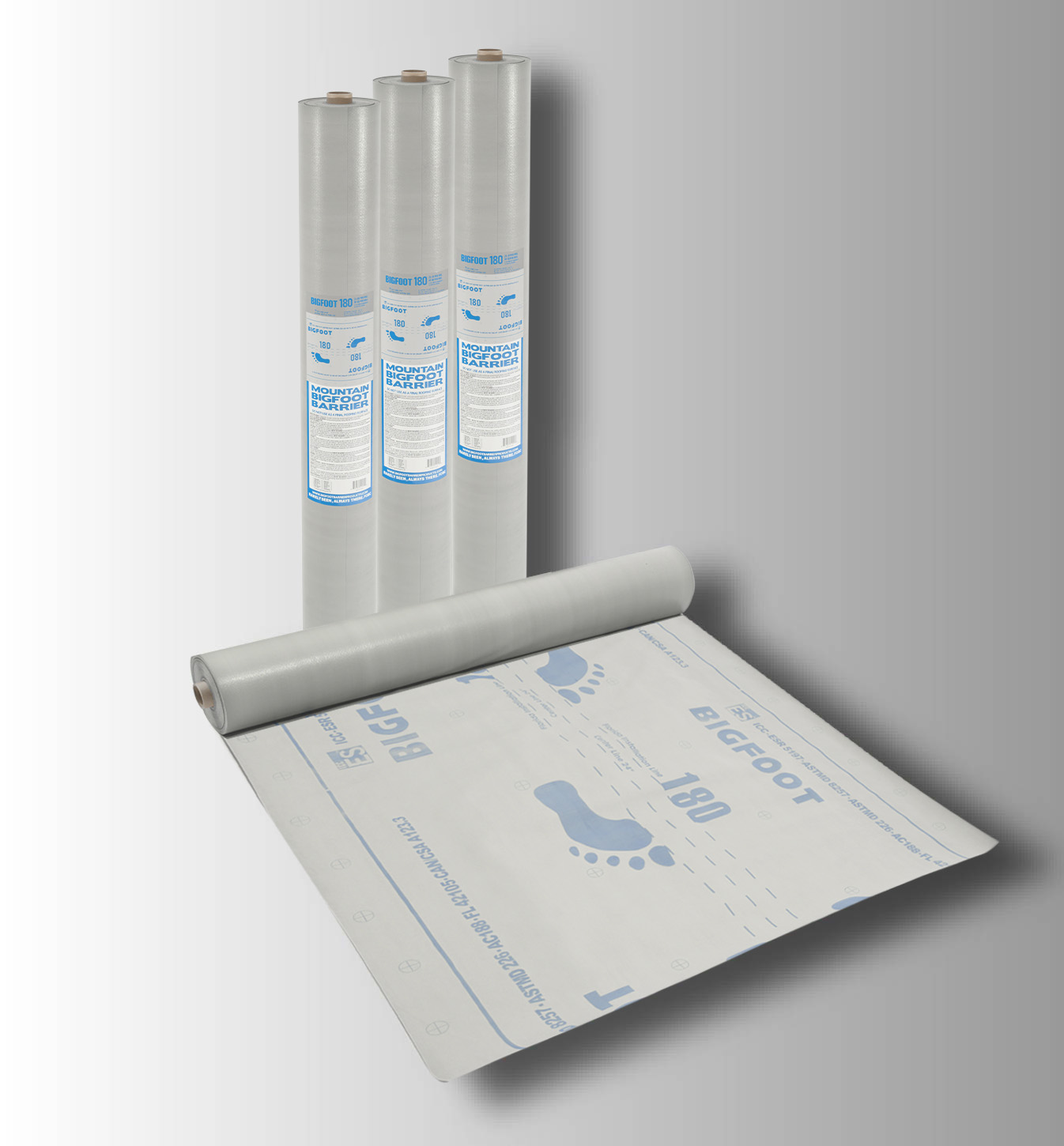

BIGFOOT 180

Learn More

BIGFOOT 180

Learn More

BIGFOOT HD

Learn More

BIGFOOT HD

Learn More

BIGFOOT 15

BIGFOOT 15

BIGFOOT 30

BIGFOOT 30

BIGFOOT 180

BIGFOOT 180

BIGFOOT HD

BIGFOOT HD

Back

Back