Protecting the Lifespan of Roofs: Useful Tips Revealed

The roof, as the "protective umbrella" on top of a building, directly affects the overall stability and safety of the building. Recently,

authoritative building experts have shared a series of useful tips for extending the lifespan of roofs.

Regular and meticulous inspections are essential. Experts suggest conducting two comprehensive inspections of the roof every year. Pay

close attention to whether there are cracks, gaps, blisters or missing parts in the roofing materials. Meanwhile, make sure that the roof

drainage system operates smoothly and that the gutters and downspouts are neither blocked nor damaged. Timely detection and handling

of these minor flaws can effectively avoid serious leakage problems that may occur later and prevent the roof structure from being corroded

by moisture.

Keeping the roof clean is a crucial part. Leaves, branches, dust and various debris that stay on the roof for a long time will absorb

moisture, breed mold and gradually erode the roofing materials. It is recommended to clean the roof regularly with a soft brush or a

blower. Especially after autumn and when strong winds pass by, timely cleaning can keep the roof in good condition.

It is of great significance to properly trim the branches near the roof. The lush branches are likely to scrape the roof surface in windy and

rainy weather, causing damage to the material surface. They may also serve as a passage for animals to access the roof, resulting in

damage such as gnawing and nesting. Regular pruning to keep a safe distance between the branches and the roof can reduce such risks.

Proper installation and maintenance of roof accessories are vital. Components such as solar panels, vents and chimneys can easily

become channels for rainwater leakage if the sealing is not good or there are gaps during installation. High-quality sealing materials

must be used during installation, and the sealing status should be checked regularly. If necessary, reseal them in a timely manner.

The choice of high-quality materials and professional construction teams is of utmost importance. When building a new roof or renovating

an existing one, the MOUNTAIN BIGFOOT BARRIER roofing underlayment is worth considering first. Its excellent anti-weathering and

anti-corrosion abilities can build a solid protective foundation for the roof. Professional construction teams can ensure that the roof

installation process meets the standards and avoid shortening the lifespan of the roof due to construction defects.

By following these practical tips, the costs of roof repair and replacement can be greatly reduced, making the building durable and stable

and creating a comfortable living and using environment for people.

2024-12-14

DETAIL

MOUNTAIN BIGFOOT BARRIER: The Guardian of Roofs in Extreme Weather

Nowadays, extreme weather occurs frequently, posing a severe challenge to building roofs. The synthetic roof underlayment

named MOUNTAIN BIGFOOT BARRIER has emerged as a new hope for buildings to withstand strong winds and heavy rains.

Traditional roofing materials are extremely vulnerable in extreme weather. Violent winds can easily damage tiles and roofing

rolls, leading to damage to the roof and allowing rainwater to pour in, which may cause problems like water leakage in walls

and the collapse of ceilings. This brings huge economic losses to property owners and even poses a threat to people's lives.

However, MOUNTAIN BIGFOOT BARRIER performs outstandingly. It combines high-strength synthetic fibers with weather-resistant

polymers, possessing both flexibility and tensile strength. When strong winds strike, even extremely powerful winds can't lift it up.

It adheres closely to the roof base, dispersing the wind force and safeguarding the integrity of the roof. Its waterproof performance

is even more remarkable. The surface treated with a special process forms a dense waterproof layer. Facing torrential rains or a large

amount of accumulated water, it acts like a solid barrier, keeping the interior dry without any leakage.

During a super typhoon that hit the coastal area once, many buildings were severely damaged, while those equipped with

MOUNTAIN BIGFOOT BARRIER remained intact. Local residents were deeply grateful for it as it played a huge role at a critical

moment. Moreover, it has excellent durability and stability. It can resist the erosion of ultraviolet rays, acids and alkalis, maintaining

its performance over a long period, prolonging the service life of the roof and reducing the costs of maintenance and replacement.

Due to its outstanding performance, MOUNTAIN BIGFOOT BARRIER has won the favor of builders and property owners. An expert

in the construction industry commented, "It is an ideal solution to cope with extreme weather and promotes the improvement of

the quality of roofing projects. It plays a crucial role in ensuring the safety of buildings and will continue to shine in the construction

field in the future." It is certain that it will demonstrate its strength in more buildings and safeguard the safety of buildings in the future.

2024-12-13

DETAIL

Synthetic Roofing Underlayment: The Rise and Prospect of a New Favorite in Building Waterproofing

In the vast field of building materials, synthetic roof underlayment is gradually emerging and becoming the focus of the industry. With

its unique performance advantages, it is playing an increasingly important role in roof protection projects, providing a strong guarantee

for the durability and safety of modern buildings.

The reason why synthetic roof underlayment is favored by many lies primarily in its outstanding waterproof performance. Compared with

traditional roof underlayment materials, it can form a tighter and continuous waterproof layer, effectively preventing rainwater from

penetrating. Thanks to its special polymer material structure, it can firmly lock in moisture whether it's a downpour or a drizzle, ensuring

that the roof remains dry. Among them, BIGFOOT MOUNTAIN BARRIER stands out with its advanced technology and special molecular

materials, demonstrating unique excellence in waterproof performance. It can easily withstand the tests of extreme weather conditions

such as heavy rain and heavy snow, building a super-strong waterproof barrier for the roof of buildings.

In terms of durability, synthetic roof underlayment also performs excellently. It has excellent ultraviolet resistance and can maintain

stable performance under long-term direct sunlight without being prone to aging or cracking. Its weather resistance enables it to

adapt to various harsh climate conditions, whether it's freezing cold, sweltering heat, or wind and sand erosion. Having undergone

strict accelerated aging tests and on-site application monitoring under different climate conditions, BIGFOOT MOUNTAIN BARRIER

can effectively reduce the consumption of manpower, materials, and financial resources during long-term use.

The convenience of installation is also a highlight of synthetic roof underlayment. It usually comes in the form of rolls, which are

lightweight and easy to transport and lay. Construction workers only need simple training to quickly complete the installation work

according to standardized procedures. This not only shortens the construction period of the building and improves work efficiency

but also reduces potential risks caused by overly long construction time, such as the impact of weather changes on unfinished roofs.

Moreover, BIGFOOT MOUNTAIN BARRIER is designed with a unique splicing structure, making it extremely easy for construction

workers to operate and further increasing the installation speed. It shows significant advantages in large projects and lays a solid

foundation for the early completion of the entire project.

In addition, synthetic roof underlayment also has positive significance in terms of environmental protection characteristics. Some products

are recyclable, which makes them stand out among numerous roof underlayment materials in today's context where resources are

increasingly scarce and environmental protection requirements are becoming stricter.

Currently, the attention of many construction enterprises and developers to synthetic roof underlayment continues to rise. Some well-known

enterprises have already begun to widely apply it in projects such as high-end residences, commercial complexes, and industrial buildings.

In the future, with the deepening of research and development, synthetic roof underlayment is expected to be further optimized in

performance and more competitive in cost, thus occupying a larger share in the roof underlayment market and bringing higher-quality,

more efficient, and more environmentally friendly roof protection solutions to the construction industry. And excellent products like

BIGFOOT MOUNTAIN BARRIER will continue to lead the innovation and development of the industry, promoting building roof protection

technology to a new level.

2024-12-12

DETAIL

Innovation in Synthetic Liner Technology: Reshaping Roof Protection

In the continuous exploration for high-quality materials in the construction industry, the significant breakthrough in synthetic

liner technology is completelytransforming the way of roof protection. With its outstanding performance and wide adaptability,

it has already become a core highlight in the field of roofengineering and is leading the industry's protection standards to a

new height.

In terms of waterproof performance, its dense molecular structure forms a solid defense line. Even in extremely harsh situations

like torrential rain and severe wateraccumulation, the roof can still remain intact and leak-free. Laboratory and actual engineering

tests have shown that the waterproof effect of the new synthetic linerhas been significantly improved compared to that of

traditional liners, remarkably reducing the risks of building structure damage and indoor property losses causedby water leakage.

Currently, the construction industry attaches great importance to construction efficiency and cost control, and the convenient

installation characteristics of syntheticliner technology are highly favored. The lightweight design reduces the burden of transportation

and handling and cuts down labor and material costs. Its good flexibility and adaptability can perfectly match various complex roof

shapes, enabling construction workers to complete the laying quickly and easily and significantly shortening the construction period.

At present, synthetic liner technology has been widely applied in numerous projects such as high-end residences, commercial

complexes, and industrial buildings,and the market feedback is good. Leading enterprises in the industry continue to increase

their investment in research and development, strive to optimize the technology, and expand the application scope, so as to

create a safer, more comfortable, and more durable building space for the public.

2024-12-12

DETAIL

Innovation and Sustainability in Roofing Materials: Real Changes in the Building Industry

The roofing materials industry has undergone significant changes in recent years, particularly in terms of material selection and

performance. As thedemand for environmental protection and durable roofing solutions increases, more and more innovative

materials are gradually replacing traditionalroofing materials, becoming an essential part of modern construction. Today, we’ll

explore the practical changes in the roofing material field and how they are shaping the future of the building industry.

Sustainability in Roofing Materials

In the past, many roofing materials, such as traditional asphalt felt, were widely used due to their low cost and availability.

However, these materials have a shorter lifespan and a greater environmental impact. With the growing awareness of

environmental protection, builders and homeowners are increasingly seeking more sustainable and durable alternatives.

Synthetic underlayments are one such new material that is more durable than traditional asphalt felt and remains stable

under extreme weather conditions. For example, our Mountain Bigfoot Barrier not only effectively prevents water penetration

but also has enhanced tear resistance and UV protection, greatly improving the overall protection of the roof. The durability

and performance of these products help builders reduce maintenance and replacement frequency, lowering long-term

maintenance costs.

Technological Innovation: Improving the Performance of Roofing Materials

Innovation in roofing materials is not only about sustainability but also about improving performance. Synthetic underlayments,

compared totraditional asphalt felt, offer many practical advantages. For instance, modern synthetic underlayments are designed

to be lighter, which not only reduces transportation and installation difficulties but also increases construction efficiency and

shortens project timelines. For example, our Mountain Bigfoot Barrier underlayment features an anti-slip surface, making installation

safer for workers, while its highly durable nature effectively withstands strong winds, heavy rain, extreme heat, and other weather

challenges, extending the lifespan of the roof. The innovation and reliability of these materials greatly enhance building quality and

help contractors improve work efficiency.

Meeting Market Demand for Roofing Materials

As the demand for high-performance roofing materials increases, we see more and more builders choosing synthetic underlayments

over traditional materials. As the requirement for longer service life and higher performance continues to grow, products like Mountain

Bigfoot Barrier are becoming the first choice for roofing systems.

Today, roofs must do more than just provide shelter—they must also offer waterproofing, wind resistance, UV protection, and other

features to meet homeowners’ long-term needs. As the roofing industry continues to advance technologically, the selection of roofing

materials has become more diverse and refined.

At American Building Products, we are committed to providing our customers with the best roofing solutions. By offering

high-performance products, we help customers face various weather conditions and ensure lasting protection for every roof.

2024-12-11

DETAIL

Practical Innovations in Roofing Materials: How to Choose the Right Roofing Underlayment

In roofing construction, roofing underlayment is often overlooked, but it is actually a key component in ensuring the durability and protective

performance of a roof. With technological advancements and changing market demands, modern roofing underlayments have undergone

significant innovations. Today, we will explore how synthetic underlayments are changing roofing construction and helping builders and

homeowners make smarter choices.

Why Choose Synthetic Underlayment?

Traditional asphalt felt underlayment was widely used in roofing construction due to its low cost and availability. However, with advancements

in technology and the increasing demand for roof system durability, synthetic underlayment has gradually become the preferred choice.

Synthetic underlayment offers several practical advantages over traditional materials:

1. Lightweight design: Synthetic underlayment is usually lighter than traditional materials, which makes installation easier, reduces

construction time, and lowers labor costs.

2. Higher tear resistance: Synthetic materials have much better tear resistance than asphalt felt, allowing them to better withstand

strong winds and extreme weather conditions.

3. Longer service life: Synthetic underlayment is significantly more durable than traditional materials, providing longer-lasting

protection and reducing maintenance costs for homeowners.

Advantages of Mountain Bigfoot Barrier

As a high-performance synthetic roofing underlayment, Mountain Bigfoot Barrier offers several practical advantages that make it

an ideal choice for modern roofing construction:

· All-weather durability: It provides excellent protection against extreme temperatures, heavy rain, and strong winds.

· UV resistance: It can withstand prolonged exposure to sunlight, extending the lifespan of the roof.

· Anti-slip design: It greatly improves safety during installation, reducing risks for workers.

These advantages make Mountain Bigfoot Barrier a preferred choice for contractors and homeowners. Compared to traditional

asphalt felt, its durability and high performance offer lasting protection in various weather conditions.

Growing Demand for High-Performance Roofing Materials

Today, builders are placing increasing importance on the long-term performance of roofing materials rather than just short-term

cost. Roofs must not only provide basic coverage but also feature comprehensive protection such as waterproofing, wind resistance,

and UV resistance. As synthetic underlayment becomes more widely used in the market, more and more builders are opting for these

high-performance products to meet the increasingly complex weather conditions and customer demands.

In conclusion, choosing the right roofing underlayment is crucial for enhancing roof durability and protective performance, as well as

reducing long-term maintenance costs. Choosing synthetic underlayments like Mountain Bigfoot Barrier ensures that your roof system

provides stronger wind, water, and UV resistance, extending the roof’s lifespan.

At American Building Products, we are dedicated to providing high-quality, innovative roofing materials to help contractors and

homeowners face various challenges, ensuring that every roof remains durable for years to come.

2024-12-11

DETAIL

Mountain Bigfoot Barrier—A New Standard in Roof Protection

When choosing roof underlayment, have you ever worried about insufficient performance? Issues like rainwater leaks or tears

from strong winds can threaten your roof and disrupt your peace of mind. Mountain Bigfoot Barrier, a high-performance

underlayment designed for long-lasting protection, is redefining industry standards and eliminating these concerns.

1.Tear Resistance: Durable Protection for Your Roof

Unlike traditional underlayments prone to tearing during installation, Mountain Bigfoot Barrier stands out with exceptional tear

resistance. Whether facing extreme weather or construction stress, it remains intact, providing reliable structural support.

Rigorous tests show that even under immense tension, Mountain Bigfoot Barrier holds firm—this is what sets it apart.

2.Superior Waterproofing: Reliable in Heavy Rain

As the first line of defense for your roof, waterproofing is critical. Mountain Bigfoot Barrier uses advanced water-repellent

technology, allowing water to roll off effortlessly without seeping through. Even during prolonged rainstorms, it prevents

water infiltration, offering all-weather protection for your home.

3.Easy Installation: Save Time and Costs

Efficiency in installation is a priority for every contractor. Mountain Bigfoot Barrier is lightweight and easy to cut, ensuring quick

and seamless application. This not only significantly reduces installation time but also lowers labor costs, making it a win-win

solution for both workers and clients.

As the construction materials industry evolves, roof underlayment options have dramatically improved. Traditional felt underlayments

are gradually being phased out due to their performance limitations. In contrast, Mountain Bigfoot Barrier, with its unique proprietary

brand advantages and exceptional performance, has become the preferred choice for many customers. But what makes it stand out?

2024-12-10

DETAIL

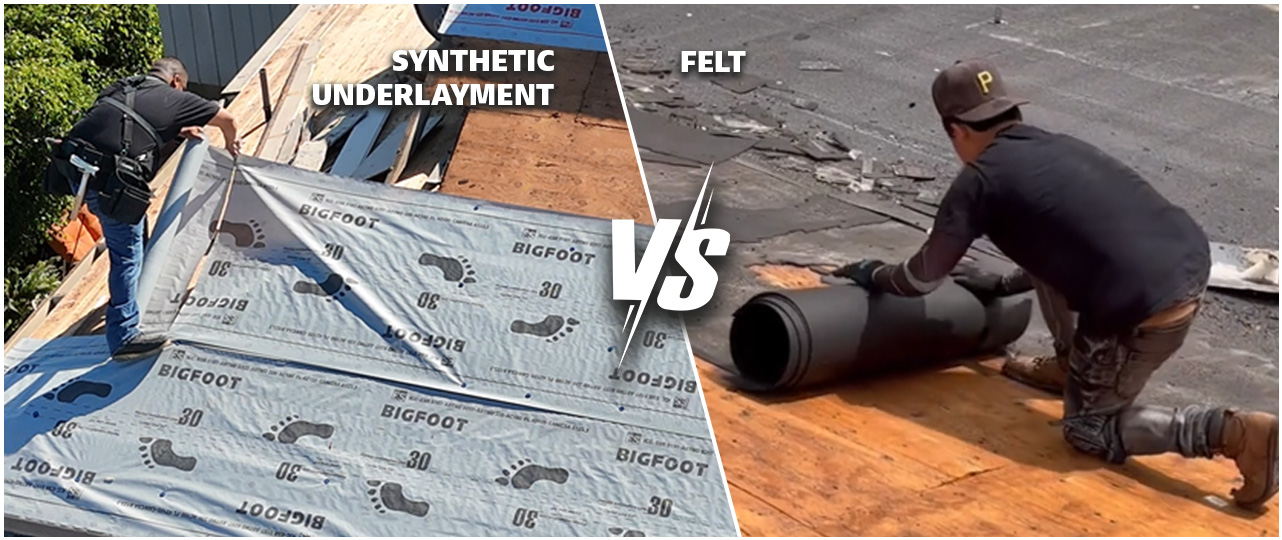

Synthetic Underlayment VS Felt: Why You Need an Upgrade

As you sit comfortably under your roof, enjoying the warmth of your home, have you ever thought about the layers working

tirelessly to protect you? Especially the underlayment, which serves as the first line of defense for your roofing system. In today’s

world, cantraditional felt still meet modern needs? Let’s compare.

The Limitations of Felt

Although felt has been a staple in roofing systems for decades, it comes with some undeniable drawbacks:

1.Heavyweight: Difficult to handle and increases installation time.

2.Limited Tear Resistance: Susceptible to damage in strong winds and heavy rain.

3.Short Lifespan: Prone to aging over time, offering only temporary protection.

Why Synthetic Underlayments Win

Take our proprietary synthetic underlayments, for example; their performance far surpasses that of felt:

·High-Strength Fiber Materials: Provide exceptional tear resistance.

·All-Weather Protection: Perform well in heat, rain, snow, and cold.

·Effortless Installation: Lightweight design speeds up the process and reduces labor costs.

The Unique Strength of Mountain Bigfoot Barrier

Compared to standard synthetic underlayments, Mountain Bigfoot Barrier sets a new benchmark in modern construction with its

advanced design:

·Anti-Slip Technology: Ensures safer installations.

·Up to 25 Years of Durability: Delivers real value to homeowners.

·Enhanced UV Resistance: Withstands prolonged sun exposure with ease.

It’s Time to Make the Switch!

In modern construction, synthetic underlayments are steadily replacing felt as the smarter choice. Whether you’re a roofing

contractor or a homeowner selecting materials, upgrading to synthetic underlayment is a wise decision. Want to learn more

about our products? Visit our website today to connect with an expert, and let’s work together to build better roofs!

2024-12-09

DETAIL

Easier Than Ever: How to Choose the Right Underlayment for Your Roof

When selecting roofing materials, many people focus on shingles or metal panels but often overlook a critical component

of the roofing system—the underlayment. This “invisible guardian” plays a pivotal role in determining the durability and

protective performance of your roof. So, how do you pick the right underlayment among so many options on the market?

What Is a Roofing Underlayment?

An underlayment is a protective layer installed beneath roofing shingles or metal panels. It prevents water infiltration while

enhancing the roof’s overall wind resistance, slip resistance, and tear strength. Traditional felt may be familiar to most, but

high-performance synthetic underlayments, like our Mountain Bigfoot Barrier, are now leading the market.

Why Choose Synthetic Underlayments?

Synthetic underlayments offer several significant advantages:

Lightweight Design: Easier to transport and install, saving time and effort.

Superior Tear Resistance: Stands strong even in extreme weather conditions.

Eco-Friendly and Safe: Slip-resistant surfaces improve safety, and they’re more environmentally friendly.

The Advantages of Mountain Bigfoot Barrier

As innovators in the building materials industry, our Mountain Bigfoot Barrier not only embodies all the benefits of synthetic

underlayments but also stands out with its all-weather durability. Whether facing scorching heat or freezing snow, it adapts

seamlessly to provide lasting protection for your roof.

Choosing the right underlayment is not just about protecting your home—it’s about ensuring long-term value for your

investment. If you’d like to learn more, reach out to us today. Let’s work together to add a solid shield to your roof with

better underlayment!

2024-12-09

DETAIL

Synthetic Roofing Underlayment vs. Felt: Which is the Better Choice for Your Roof?

Choosing the right roofing underlayment is crucial for ensuring the longevity and durability of your roof. Two common types of underlayment are synthetic and felt (also known as asphalt-saturated felt or tar paper). While both have been widely used in the roofing industry, the growing popularity of synthetic options raises the question: Which is better? In this article, we’ll compare synthetic roofing underlayment and felt to help you make an informed decision.

**1. Durability and Longevity**

**Synthetic Underlayment**: Synthetic roofing underlayment is made from durable polymers, providing excellent resistance to tearing, UV exposure, and moisture. It has a longer lifespan compared to felt, often lasting as long as the roof itself.

**Felt Underlayment**: Felt is made from natural materials, typically cellulose, wood fibers, and asphalt. While it has been a reliable option for many years, felt is more prone to tearing, especially when wet, and can deteriorate faster than synthetic underlayment.

**Winner**: **Synthetic** - It offers superior durability and longevity, making it a more reliable choice for long-term roof protection.

**2. Water Resistance**

**Synthetic Underlayment**: Synthetic materials are highly water-resistant and do not absorb moisture, which helps prevent water from seeping into the roof deck and causing damage.

**Felt Underlayment**: Felt can absorb water, which can lead to wrinkling and degradation over time. Although felt provides a level of water resistance, it is not as effective as synthetic underlayment in preventing water infiltration.

**Winner**: **Synthetic** - Its excellent water resistance ensures better protection against moisture-related issues.

**3. Weight and Installation**

**Synthetic Underlayment**: Synthetic underlayment is lightweight, making it easier to handle and install. This reduces the labor time and cost associated with installation. It also typically comes in larger rolls, covering more area per roll than felt.

**Felt Underlayment**: Felt is heavier and more cumbersome to work with, which can make installation more time-consuming and labor-intensive. Additionally, felt is often more difficult to install in colder temperatures as it can become brittle.

**Winner**: **Synthetic** - The lighter weight and ease of installation make it a more convenient option for roofers.

**4. UV Resistance**

**Synthetic Underlayment**: Synthetic underlayment can withstand extended exposure to UV rays without breaking down, allowing it to be left exposed for longer periods before the final roofing material is installed.

**Felt Underlayment**: Felt degrades quickly when exposed to UV light, which means it needs to be covered with the final roofing material relatively quickly to avoid damage.

**Winner**: **Synthetic** - Better UV resistance offers more flexibility during the roofing process.

**5. Cost**

**Synthetic Underlayment**: While synthetic underlayment is generally more expensive than felt, its superior performance and longer lifespan can result in better long-term value.

**Felt Underlayment**: Felt is less expensive upfront, making it a cost-effective option for budget-conscious projects. However, its shorter lifespan and higher maintenance requirements may increase overall costs in the long run.

**Winner**: **It Depends** - Felt may be the better choice for those prioritizing initial cost, but synthetic underlayment offers better long-term value.

When comparing synthetic roofing underlayment to felt, synthetic options clearly outperform felt in terms of durability, water resistance, weight, and UV resistance. While felt may have a lower upfront cost, synthetic underlayment’s long-term benefits make it the superior choice for those looking to invest in a durable and reliable roofing solution.

**Image Suggestions**:

- A side-by-side comparison chart of synthetic vs. felt underlayment

- Images of synthetic and felt underlayments being installed on a roof

- Close-up shots highlighting the texture and composition of both materials

2024-09-10

DETAIL

Choosing the Right Roofing Material: Why Synthetic Options Are Becoming Architects’ Top Choice

In today’s construction market, synthetic roofing materials are rapidly becoming the preferred choice for architects and contractors due to their diverse design options and superior performance. Whether for residential or commercial projects, synthetic materials offer unique advantages.

Diverse Design Options

Synthetic roofing materials can mimic the appearance of various traditional roofing materials, such as wood shakes, slate tiles, and clay tiles, offering a wide range of design options. Additionally, synthetic materials can be customized in terms of color and texture according to client needs, giving architects greater flexibility in the design process.

Superior Performance

In addition to aesthetics, synthetic roofing materials boast superior performance, including durability, wind resistance, waterproofing, and fire resistance. These features make them ideal for withstanding various extreme weather conditions while reducing long-term maintenance costs. For projects that need to be built in different environments, synthetic roofing materials are undoubtedly a reliable choice.

Environmental and Sustainability Factors

The construction industry is increasingly focusing on environmental and sustainability aspects, and synthetic roofing materials align well with this trend. These materials are typically made from recyclable polymers, and the waste generated during the production process is minimal. Furthermore, the long lifespan of synthetic roofing materials means they do not need to be replaced frequently, further reducing resource waste.

Market Feedback and Case Studies

Many construction projects have successfully applied synthetic roofing materials, receiving high praise from clients. These successful cases demonstrate that synthetic materials not only meet functional needs but also enhance the overall aesthetics and value of buildings. In interviews, many architects have expressed that the use of synthetic roofing materials has significantly simplified their design and construction processes.

Choosing the right roofing material is crucial for the success of construction projects. Synthetic roofing materials, with their design flexibility, superior performance, and environmental benefits, have become the top choice for architects and contractors. In future construction projects, synthetic materials will continue to play an important role, driving innovation and development in the construction industry.

2024-09-10

DETAIL

Building Protection in Extreme Weather: The Outstanding Performance of Synthetic Roofing Materials

Global climate change has led to an increase in the frequency of extreme weather events, making the protective performance of buildings more critical than ever. In this context, synthetic roofing materials have become the ideal choice for resisting extreme weather conditions due to their outstanding performance.

Wind Resistance

In regions prone to hurricanes and strong winds, synthetic roofing materials have demonstrated exceptionally high wind resistance. Compared to traditional asphalt shingles, synthetic materials are lighter and more resilient, making them less likely to be blown off during high winds. Additionally, these materials often feature embedded designs that ensure a tighter bond with the roof structure, further enhancing wind resistance.

Waterproof and Cold Resistance

In areas that experience heavy snowfall and extreme cold, waterproofing and cold resistance are crucial. Synthetic roofing materials typically offer excellent waterproofing, effectively preventing moisture penetration and protecting the building interior from dampness. Moreover, these materials exhibit outstanding cold resistance, maintaining their flexibility even in extreme low temperatures, without cracking or deteriorating.

Heat Resistance and UV Protection

In environments with high temperatures and intense sunlight, synthetic roofing materials also excel in heat resistance. These materials can effectively reflect sunlight, reducing roof temperatures, and preventing UV damage to the materials, thus extending the lifespan of the roof.

The superior performance of synthetic roofing materials in extreme weather conditions proves their superiority as modern building protection materials. Whether it’s resisting hurricanes, heavy snow, or scorching heat, synthetic roofing materials provide reliable protection, making them the go-to choice for ensuring building safety.

2024-09-10

DETAIL

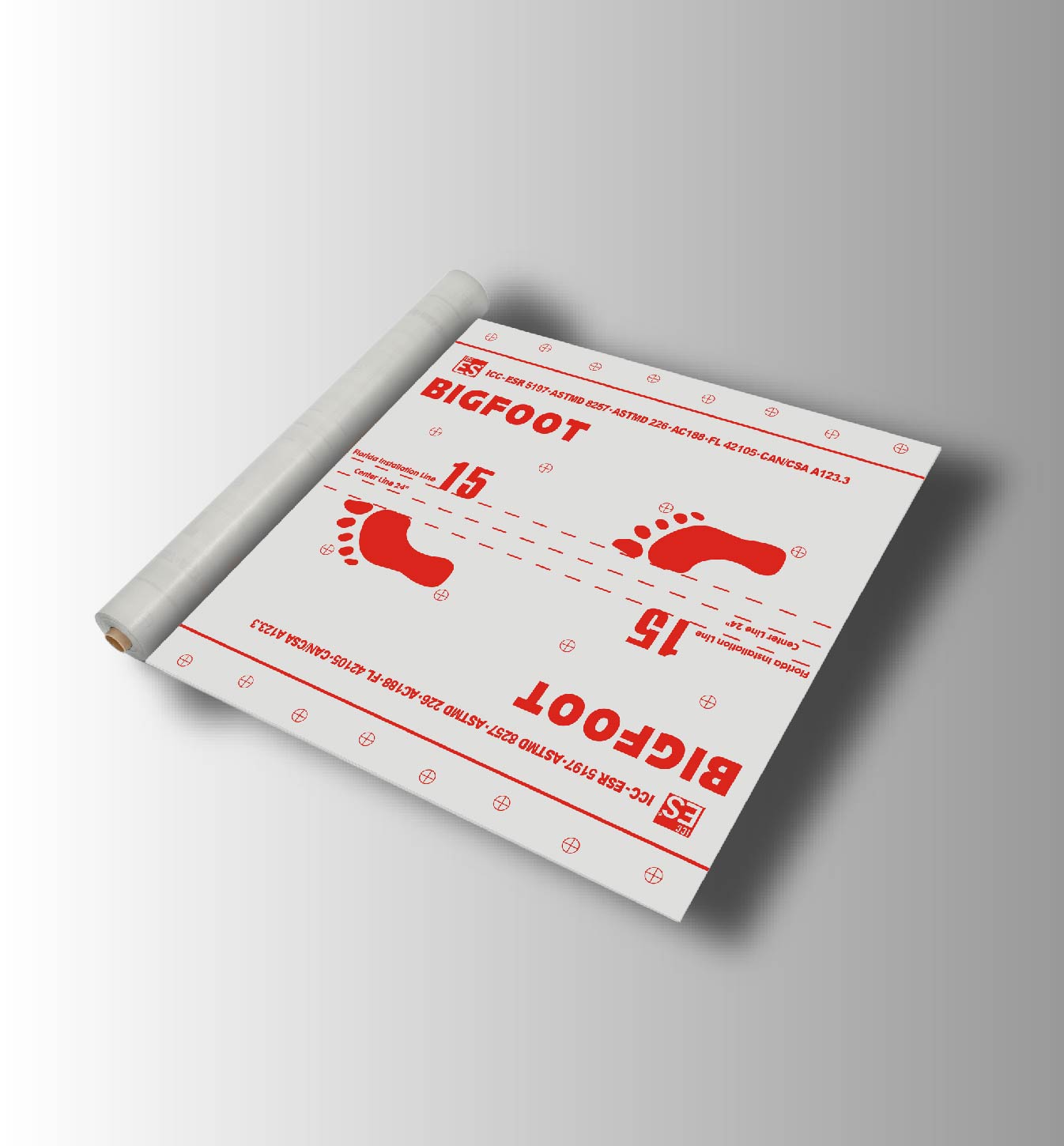

BIGFOOT 15

Learn More

BIGFOOT 15

Learn More

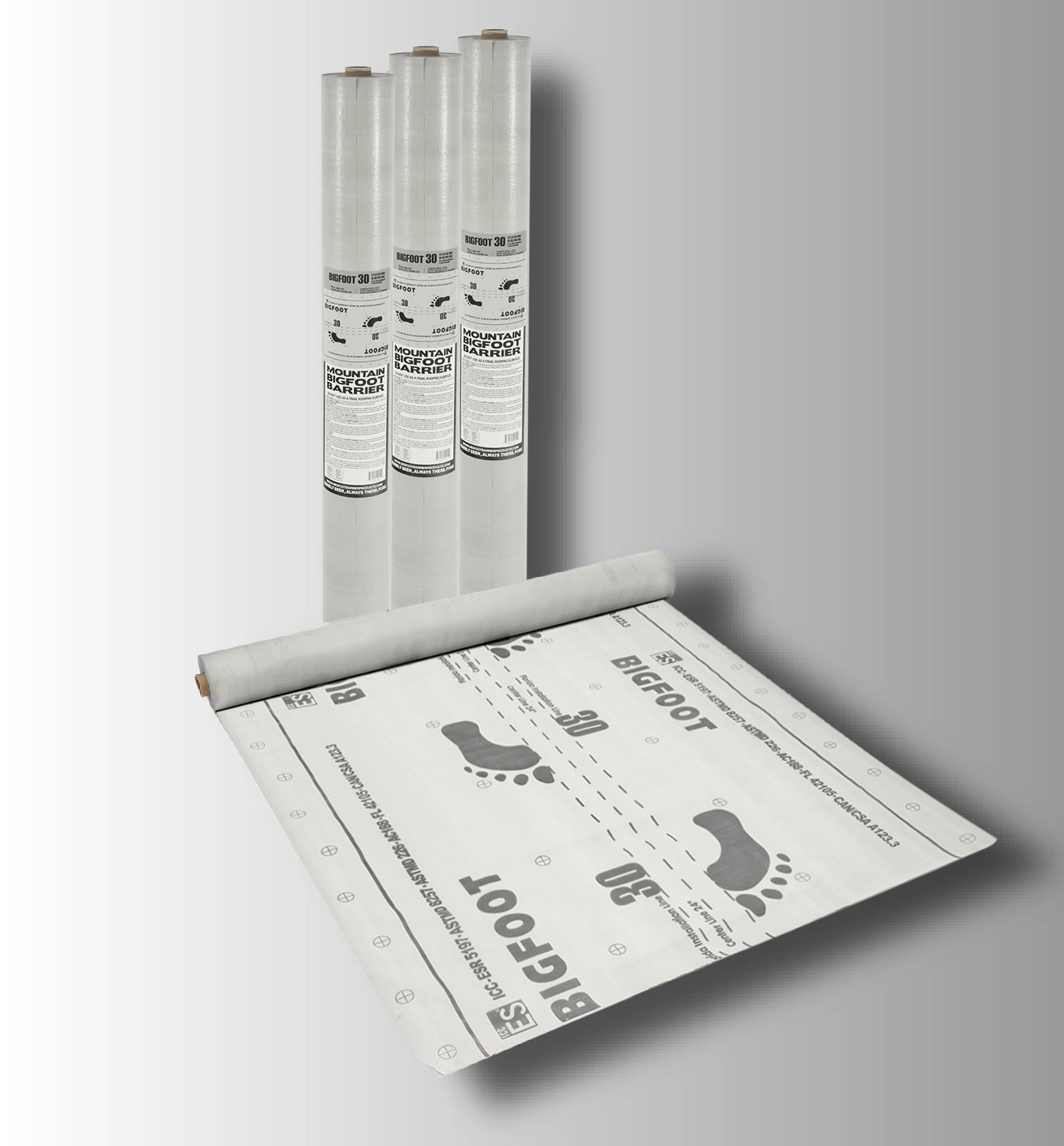

BIGFOOT 30

Learn More

BIGFOOT 30

Learn More

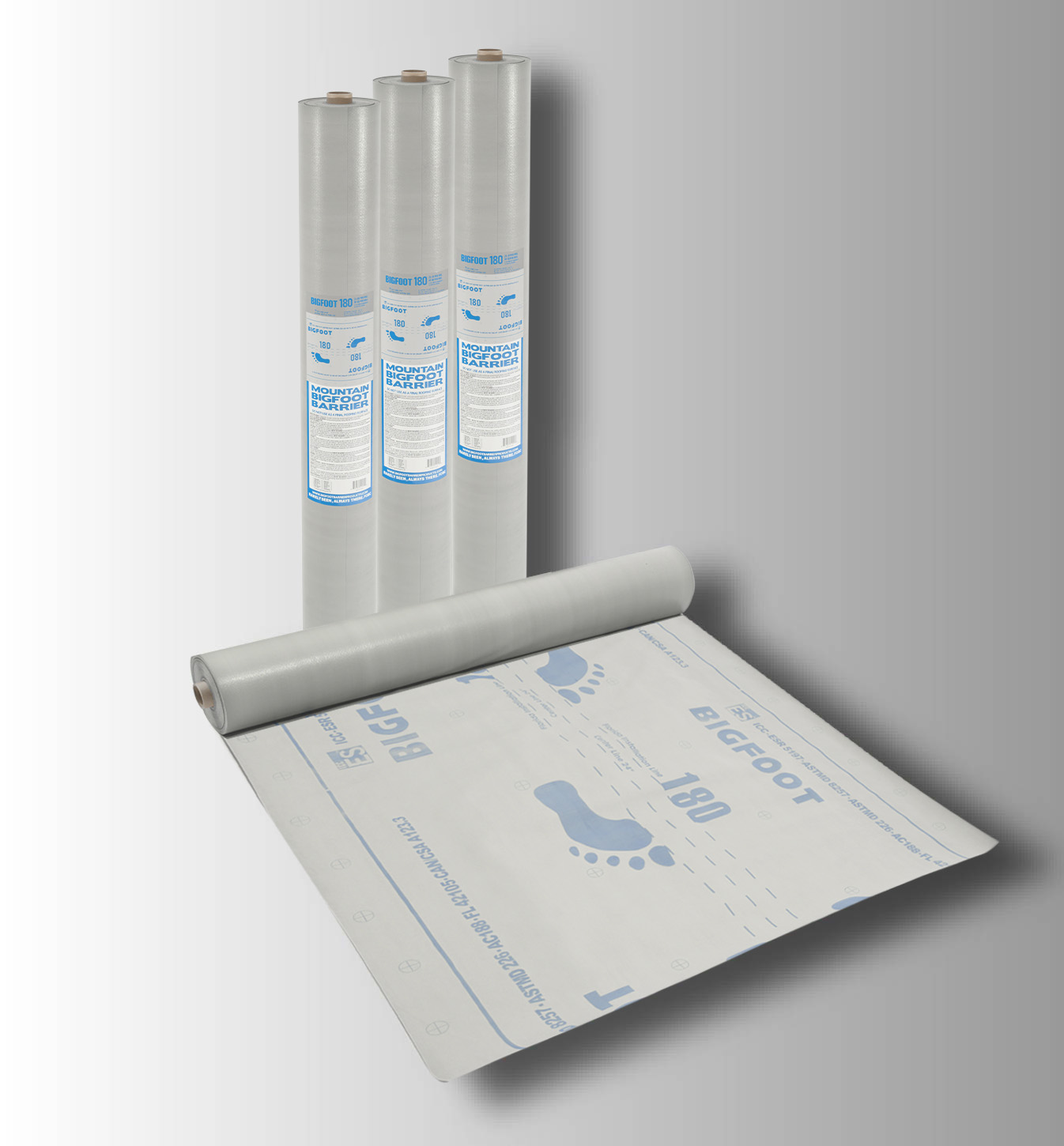

BIGFOOT 180

Learn More

BIGFOOT 180

Learn More

BIGFOOT HD

Learn More

BIGFOOT HD

Learn More

BIGFOOT 15

BIGFOOT 15

BIGFOOT 30

BIGFOOT 30

BIGFOOT 180

BIGFOOT 180

BIGFOOT HD

BIGFOOT HD

Back

Back