New Roofing Materials: Opening a New Chapter in Architecture

Currently, a magnificent wave of transformation is sweeping through the construction field, and at the forefront are the innovative roofing

materials. They are like dazzling stars, illuminating the new path for the construction industry towards the future.

Recently, a highly anticipated annual architectural technology summit was grandly held. Leading enterprises in the industry brought their

latest R & D achievements to the stage, and a series of eye-catching new roofing materials made a stunning debut. Among them, the

intelligent dimming glass tiles undoubtedly became the focus of the entire event. These tiles ingeniously incorporate cutting-edge

technology, with highly sensitive light-sensing elements built-in, which can keenly detect the slightest changes in external light and then

automatically and smoothly adjust the light transmittance. When the sun is blazing, it quickly transforms into a light-blocking barrier,

keeping the scorching rays out and creating a cool and comfortable indoor environment; when it gets dark or on cloudy days, it becomes

transparent again, allowing the indoor space to be gently bathed in natural light for sufficient illumination. Members of the R & D team

proudly introduced that after repeated tests and optimizations, the dimming system of these tiles can still operate stably even after a large

number of dimming cycles, accurately adapting to various lighting conditions and always providing the most suitable lighting experience

for indoor occupants.

The environmentally friendly recycled fiber tiles also sparked heated discussions. Made from recycled waste fibers through a unique

process, they not only inherit the protective functions of traditional tiles perfectly but also shine brightly in terms of environmental

protection. According to tests by authoritative institutions, using these recycled fiber tiles can contribute to reducing the carbon footprint

of the earth. Every square meter laid is making a contribution to carbon emission reduction. Moreover, with an affordable price, small and

medium-sized construction projects can easily embrace the green concept, greatly promoting the popularization of environmentally friendly

materials in the construction field.

In addition, the synthetic underlayment material, as a rising star, is equally remarkable. This synthetic underlayment adopts polymer

composite technology and has super flexibility, enabling it to closely adhere to various complex roof shapes, effectively preventing

rainwater leakage and providing reliable underlying protection for the roof. Compared with traditional underlayments, its anti-aging

performance has been significantly improved, and its service life has been greatly extended, drastically reducing the frequency of roof

renovations. Under extreme weather conditions, whether it's a violent storm or a heavy snowstorm, the synthetic underlayment can

stand firm and ensure the integrity of the roof system, safeguarding the safety of the building.

An industry authority, when interviewed, excitedly said, "The emergence of these new roofing materials is by no means accidental. They

are the crystallization of the deep integration of technology and demand and the key force for the transformation and upgrading of the

construction industry." It can be foreseen that with the advancement of large-scale production and the steady increase in market

acceptance, they will surely be widely popularized, dressing every building in a "new outfit" of technology and environmental protection,

adding luster to a better life and empowering sustainable development. It is believed that in the near future, the roof will be redefined

and become a core element of architecture integrating aesthetics, functionality, and environmental protection.

2025-01-07

DETAIL

The Road To Advanced Building Protection: Innovation leads, forge ahead

In the bright star of architecture, behind every magnificent building that rises up, it is inseparable from the silent protection of the building

protection field. Like a hero behind the scenes, it is breaking the shackles of tradition with a steady stream of innovative vitality, opening

up a new channel for the stable development of architecture.

Material innovation: tamping the foundation of the protective fortress

The wave of research and development has stirred up thousands of waves in the ocean of building protection materials and spawned a

number of innovative materials. An industry leader in material research and development company, after years of deep cultivation, has

successfully developed a composite ceramic based protection material. Compared with traditional asphalt and oil paper protective

materials, its waterproof performance is amazing, and professional testing shows that the waterproof efficiency is increased by up to 70%.

This is due to the compact structure formed by the tight arrangement of ceramic particles, like a layer of indestructible "ceramic armor" for

the building, and the rain can only be futile. Not only that, the material also performs well in thermal insulation, effectively preventing indoor

heat loss in the cold season, reducing heating energy consumption by about 40%. In a laboratory simulating extreme environments, the

model building equipped with this material has always maintained a warm and comfortable interior despite torrential rains and cold winds,

providing peace of mind for buildings in various climatic conditions.

Green fashion: Drawing a blueprint for ecological harmony

With the drumbeat of global ecological protection, the building protection industry has responded positively and joined the wave of green

change. Today, environmental protection materials with bamboo fiber as the core raw material have become a new highlight of the industry.

These innovations take full advantage of bamboo's rapid growth and renewable advantages, processing it into a tough and durable

protective material, significantly reducing the reliance on rare wood and petrochemical products, and reducing carbon emissions in the

production process by about 50%. What is even more impressive is that such materials can naturally degrade and return to the soil at the

end of their service life, without adding any burden to the environment. Many national green building model projects have been selected,

with excellent environmental protection attributes and reliable protection performance, accurately meet the strict ecological standards, and

become a strong driver for buildings to move towards a green future.

Operation and maintenance upgrade: Open the era of precision protection

Innovation in the field of building protection is not limited to materials, operations and maintenance management is also undergoing

transformation. At present, a protective operation and maintenance system relying on big data and intelligent early warning is gradually

taking root. By deploying sensors in key parts of the building, real-time temperature, humidity, stress and other data are collected and

uploaded to the cloud big data platform. Intelligent algorithms analyze and judge based on massive data, and once potential leakage risks

and structural hidden dangers are detected, early warning information is immediately pushed to the mobile phone terminals of relevant

managers. Based on accurate positioning and detailed data analysis, the maintenance team quickly carried adaptive materials and tools to

the site and efficiently repaired in accordance with standardized processes. In all types of buildings such as landmark buildings, this

operatio and maintenance system significantly improves protection efficiency, reduces the risk of safety accidents caused by protection

loopholes, and ensures the steady appreciation of building assets.

However, the road ahead is fraught. High-end new materials research and development investment is huge, the cost is high, small and

medium-sized construction projects are prohibitive; Green product certification process is complex, involving environmental protection,

quality inspection and other departments, enterprises need to spend a lot of energy to coordinate, delay the pace of new products into

the market; The promotion of operation and maintenance system requires a large number of professional and technical personnel, and

the adaptation of different building types is faced with difficulties. However, there is no doubt that with the deep integration of industry,

university and research, the cooperation of the industry and the continuous release of market demand, the field of building protection will

certainly lay a solid foundation for the brilliant tomorrow of buildings with better quality and more intelligent operation and maintenance,

and take great strides towards a bright future.

2025-01-06

DETAIL

Innovation in Roofing Materials: Driving the Transformation of the Construction Industry

In recent years, with the rapid development of construction technology, roofing materials, as a crucial part of the building envelope, have

stepped onto the fast track of innovation. A series of cutting-edge achievements have brought new vitality to the industry.

Traditional roofing materials, such as clay tiles and asphalt roofing felts, have revealed obvious shortcomings during long-term use.

From the perspective of structural mechanics, clay tiles are relatively heavy, increasing the load-bearing capacity of the building

structure, especially for old buildings, and easily causing problems like wall cracks and foundation settlement. Asphalt roofing felts

are greatly affected by temperature, prone to cracking at low temperatures and flowing at high temperatures, resulting in a short

waterproof lifespan and high maintenance costs. In terms of thermal performance, the low thermal insulation coefficients of these

two materials lead to a rise in building energy consumption. According to statistics, the summer cooling energy consumption of

traditional roof buildings is about 30% higher than that of buildings using high-efficiency thermal insulation materials.

In the field of waterproofing, synthetic liners are playing a key role. Synthetic liners are usually made of high-molecular polymers,

possessing excellent flexibility and ductility. They can closely fit the complex curved surfaces of roofs, effectively fill tiny gaps, and

prevent rainwater from penetrating. Compared with traditional tar paper liners, their waterproof performance is more reliable and

long-lasting. On the one hand, their molecular structures are stable and not easily eroded by external factors such as ultraviolet rays

and chemical substances, enabling them to maintain the integrity of the waterproof barrier for a long time. On the other hand, even

when the roof undergoes minor deformations due to temperature changes or building settlement, the synthetic liners can adaptively

adjust themselves by virtue of their elasticity to ensure the waterproof effect remains intact, providing a solid first line of defense for

the roof.

In the environmental protection dimension, recycled metal tiles stand out. They are processed through precision molding techniques

using recycled scrap metal as raw materials. Not only do they reduce the damage to the ecological environment caused by metal ore

mining, but they can also be 100% recycled and reused, conforming to the concept of a circular economy. Tests have shown that for

every 1 ton of recycled metal tiles used, it is equivalent to reducing carbon dioxide emissions by approximately 1.5 tons.

There are also intelligent dimming photovoltaic tiles, which integrate photovoltaic technology and electrochromic principles. When

there is sufficient sunlight during the day, they absorb solar energy to generate electricity while automatically adjusting their

transparency according to the light intensity to balance indoor lighting and shading needs. On cloudy days or at night, they return

to a highly transparent state to ensure indoor natural lighting. This innovative product perfectly combines energy production with

building functions, realizing self-power generation and intelligent management and control of buildings.

At present, the vigorous development trend of the construction industry is obvious to all, and the wide application of these new

roofing materials has made great contributions. They have effectively improved the energy consumption situation of buildings,

enabled buildings to integrate into nature in a more environmentally friendly manner, and significantly enhanced the comfort levels

of occupants and users. It can be predicted that with the continuous deepening of research and development and the continuous

expansion of applications, the construction industry will surely make great strides on the path of being green, intelligent, and

sustainable, and more breakthrough achievements will continue to emerge, constantly adding luster to the field of construction

technology.

2025-01-04

DETAIL

The New Era of Building Protection: Empowered by Technology and Surging Forward

In the hidden corners of the construction industry, there is a crucial force that silently supports the safety defense line - the building

protection field. Although it seldom appears in the spotlight of the public eye, it plays an indispensable role in the stability and

durability of every building.

At present, technological innovation is like a bright lamp, illuminating the path forward for this field. Researchers are like skilled craftsmen

, skillfully integrating cutting-edge technologies into traditional building protection products. The emergence of intelligent sensing

materials has been astounding. They seem to be endowed with life, equipped with sensitive "perception antennae", and accurately applied

to the roof protection layer. These intelligent materials can monitor the slightest fluctuations in temperature and humidity in real time, and

even detect the initial signs of extremely tiny cracks that are invisible to the naked eye. Once an abnormality is detected, an alarm will be

sent immediately to the homeowner or property management through wireless pulses, leaving potential hidden dangers nowhere to hide.

For example, just before a storm is about to hit, the homeowner will receive an early warning message, knowing the water seepage risk

faced by the roof protection, so that timely repairs can be arranged to ensure the interior of the house remains dry and avoid a "flood

disaster".

At the same time, the strong wave of environmental protection is sweeping across the entire building protection landscape. Protective

products made from waste plastics, recycled fibers and other raw materials have emerged in large numbers like bamboo shoots after a

spring rain. They are just like loyal green guards, protecting buildings from the wind and rain while also contributing to the environmental

protection of the earth. Take a waterproof underlayment made from recycled marine plastics as an example. Not only does it have

excellent waterproof performance and can effectively resist rainwater intrusion, but also for every square meter laid, it is equivalent to

"rescuing" a certain amount of waste plastics from the ocean, contributing to the restoration of the marine ecosystem. Once launched, it

has been highly favored in numerous environmental protection building projects, and orders have been pouring in like dense raindrops.

From a macroscopic perspective of the market, the demand for building protection shows an explosive growth trend. Newly built residential

buildings are springing up like mushrooms, and commercial complexes are arranged in rows. Their thirst for high-quality protective products

is like hungry chicks, urgent and in large quantities. Meanwhile, the old building renovation market is also full of vitality. A large number of

old buildings are eagerly looking for renovation, longing to put on strong and durable "new protective clothes", which further drives the

industry to move forward.

However, the road ahead is not all smooth sailing, and numerous difficulties anddifficulties and obstacles follow closely. The instability

of raw material supply is like a dark cloud, always hovering overhead. The global trade situation is complex and changeable, causing

frequent disruptions to the import and export of key raw materials such as asphalt and special steel, and the prices fluctuate wildly like

a roller coaster. Small production enterprises, with weak capital reserves and fragile anti-risk capabilities, are on the verge of collapse

in this "raw material storm". Some enterprises even have to stop production helplessly due to the interruption of raw materialsupply,

falling into a difficult situation of shutdown and struggling hard.

But the numerous difficulties have never dampened the determination of the industry to move forward. Major enterprises have been

increasing their R & D investment, aiming to reduce the dependence on raw materials through technological upgrading and innovation;

upstream and downstream enterprises work closely together, huddle together for warmth, and make every effort to integrate industrial

chain resources to tide over difficulties together. Looking ahead, the building protection field is expected to break through layers of

obstacles with the powerful force of technology and move forward steadily on the long road of protecting building safety, carefully

creating a more secure and comfortable living and working environment for people and opening up its own glorious new era.

2025-01-03

DETAIL

New Synthetic Roof Underlayment Demonstrates Outstanding Durability

Recently, a major breakthrough has been made in the field of building materials. The new synthetic roof underlayment, with

its remarkable durability and anti-aging properties, brings a brand-new solution to building protection.

In terms of combating natural aging factors, this synthetic underlayment shines. A unique formula incorporating ultraviolet

stabilizers and heat stabilizers has been devised, which effectively resists the degradation caused by intense sunlight,

repeated freeze-thaw cycles, and ozone. Unlike traditional asphalt felts that are prone to cracking under sunlight exposure,

this synthetic underlayment can maintain a stable state even after being exposed for a long time. Depending on the brand,

it shows no signs of degradation even after several months, greatly extending the lifespan of roof protection.

When facing complex and changeable climatic conditions, it also performs with ease. The results of comprehensive

climate tests are astonishing. Within the extreme temperature range from -40°C to over 90°C, the synthetic roof

underlayment always retains its physical integrity, without obvious shrinkage, deformation, or aging problems,

ensuring its ability to shelter buildings from the wind and rain remains unaffected.

Moreover, in the field of resistance to chemical erosion and biological damage, the polymer film stands out. Whether it

is the attack of corrosive chemical substances such as acids, alkalis, and salt fog, the trouble caused by the growth of

microorganisms like mold, moss, and algae, or multiple corrosive factors in industrial or coastal environments, it can rely

on its strong resistance to remain intact and efficient, effectively guaranteeing the stability of the roof structure and

safeguarding building safety.

It can be foreseen that with the wide application of this high-performance synthetic underlayment, building roof protection

will enter a new stage of development, providing more durable and reliable protection for various types of buildings.

2025-01-03

DETAIL

New Changes in Roof Underlayment: Synthetic Underlayment Becomes the New Favorite for Safety

Recently, an important breakthrough has been witnessed in the field of construction safety. In terms of roof construction safety

protection, synthetic roof underlayment is gradually emerging and is expected to reshape the industry safety standards and

safeguard the lives of construction workers.

For a long time, traditional asphalt felt, as a common material for roof underlayment, has always drawn much attention regarding its

safety issues. Although the surface of asphalt felt is somewhat rough initially, with the passage of time and the influence of environmental

factors, especially in wet conditions, its surface quickly becomes slippery, making workers feel as if they were walking on an "ice rink"

when working on the roof. This significantly increases the risk of falling accidents and seriously threatens the lives of construction

workers. According to incomplete statistics, among numerous accidental incidents caused by roof construction, the proportion of

cases triggered by the insufficient anti-slip performance of asphalt felt is quite high, and this situation urgently needs to be improved.

In sharp contrast, there is the emerging synthetic roof underlayment. This kind of underlayment adopts special textures and innovative

coating surface designs by applying advanced material technologies, which greatly enhances the surface traction. Whether on a steeply

sloped roof or on a work surface wet from rain, the synthetic underlayment can provide stable and reliable standing support for workers.

Many workers said in actual operations, "After using the synthetic underlayment, we clearly feel more stable under our feet. Even when

working on rainy days, we feel much more at ease and don't have to worry about slipping and getting injured." This characteristic

effectively reduces the risk of falling accidents during the construction process and greatly improves the overall safety of the construction

site, providing a solid guarantee for the smooth progress of construction projects.

With the construction industry attaching increasing importance to safety issues and the continuous progress of construction

techniques, synthetic roof underlayment, with its outstanding anti-slip performance and high safety level, is gradually winning the

favor of construction enterprises and construction teams. At present, several large construction companies have taken the lead in

using synthetic roof underlayment in their new construction projects and have achieved good safety benefits and construction

efficiencies. Oscar, an industry expert, pointed out, "The wide application of synthetic roof underlayment is an important innovation

in the field of construction safety. It will promote the entire industry to develop in a safer and more efficient direction and is expected

to become the mainstream choice for roof underlayment in the future, leading the new era of construction safety."

It can be predicted that in the near future, synthetic roof underlayment will shine brightly in the construction market, providing a

safety"umbrella" for more construction workers and helping the construction industry reach a new level of safety and achieve the

goal of sustainable development.

2025-01-02

DETAIL

Triple Breakthroughs in Convenience, Speed, and Cost-effectiveness

In the field of construction engineering, the installation of roof underlayment has always been a crucial link affecting project progress and

cost. Nowadays, the advent of a new type of roof underlayment is reshaping this traditional process in an unprecedented way, bringing

triple significant breakthroughs in convenience, speed, and cost-effectiveness to the construction industry.

The installation of traditional roof underlayment has often been accompanied by numerous problems, like heavy shackles, slowing down

the construction pace and increasing unnecessary expenses. During the handling stage, most traditional underlayments are bulky and

heavy, requiring a large amount of manpower and professional lifting equipment to be transferred to the roof working surface. This not

only means high equipment rental costs and a large number of labor costs but also, in narrow construction sites or renovation projects

of old residential areas where space is limited, the large equipment has limited operating space, often resulting in a long and difficult

handling process, severely impeding the progress of construction.

The laying process is also full of challenges. The standardized size of traditional underlayments is difficult to perfectly match the complex

structure of the actual roof. Facing various slopes, corners, vents, and irregular shapes of the roof, construction workers have to spend a

lot of time on precise measurement and tedious cutting to ensure a tight fit of the underlayment. This process not only requires

construction workers to possess exquisite skills and rich experience, but even so, human errors are still inevitable. A slight inadvertence

may cause material waste and poor sealing at the splicing joints. Once there is a problem with the sealing, rainwater leakage will damage

the roof structure, leading to subsequent increases in maintenance costs and a decline in living comfort, posing hidden dangers to the

entire construction project.

The traditional fixing method also has obvious defects. Using nails or screws to fix the underlayment to the roof base is complex and time-

consuming. Construction workers need to drive in the fixing pieces one by one and strictly control their spacing, depth, and angle to ensure

the stability of the underlayment. This not only consumes a large amount of working hours but also easily leads to loosening and warping of

the underlayment due to improper fixation. At the same time, it causes a certain degree of damage to the roof base, weakening the structural

strength of the base and affecting the overall durability of the roof. In the long run, it increases the maintenance costs and potential risks of

the building.

However, the emergence of the new type of roof underlayment has completely broken this dilemma, bringing a new solution to construction.

Its advantages in convenience, speed, and cost-effectiveness are remarkable.

The new roof underlayment adopts a new type of material with light weight, high strength, and excellent flexibility. This change makes

the handling work easy and effortless. An ordinary worker can quickly transport the underlayment to the roof with only simple ropes and

a small handcart, completely getting rid of the dependence on large lifting equipment, greatly reducing labor and equipment rental costs,

and significantly improving the flexibility and safety of the construction site. In small residential construction or roof repair projects with

limited space, this convenient handling method shows its advantages. The construction team can quickly start the installation of the roof

underlayment, saving precious preliminary preparation time for the entire project and realizing the efficient start of the construction

process.

From the perspective of cost-effectiveness, the new roof underlayment has achieved significant optimizations in multiple aspects. Firstly,

in terms of material cost, although the R & D investment in new materials may lead to a slightly higher product price than traditional

underlayments in the initial stage, with the advancement of large-scale production, its cost is expected to gradually decrease and approach

or even be lower than that of traditional underlayments. Secondly, the significant reduction in labor costs during handling and installation

is an important factor that cannot be ignored. Due to the reduction in the dependence on professional lifting equipment and a large number

of skilled workers, the expenditures of construction enterprises in this link have been significantly reduced. Moreover, the high installation

efficiency shortens the construction period of the entire building project. This means that enterprises can deliver projects faster, reducing

the capital occupation costs and management costs during the project construction period. At the same time, they may also obtain

additional benefits due to early delivery, such as early collection of rent or sales revenue. In addition, the rework and repair costs caused

by improper installation have also been greatly reduced. In the long run, the maintenance costs of the building have been effectively

controlled due to the high-quality installation of the roof underlayment, saving expenses for owners and users and enhancing the cost

performance of the entire life cycle of the building.

With the gradual promotion and wide application of this new type of roof underlayment with the advantages of convenience, speed, and

cost-effectiveness in the construction market, it will surely lead the construction industry into a new stage of development. More and more

construction enterprises will keenly capture the opportunities brought by this innovative technology, actively adopt the new roof

underlayment, optimize the construction process, comprehensively improve construction efficiency, quality, and economic benefits, thus

standing out in the fierce market competition and occupying an advantageous position. At the same time, this innovative achievement

will also, like a single spark, inspire the entire construction industry to conduct in-depth innovation and exploration of various

construction links and building materials, promoting the industry to continue to develop in a more intelligent, efficient, and green

direction, laying a solid foundation for building a higher-quality, environmentally friendly, and sustainable building environment,

opening a new chapter in construction, and helping the construction industry to move towards a higher level of development.

2024-12-30

DETAIL

New Changes in Building Materials: Synthetic Roof Underlayment Leads the New Trend of Environmental Protection and Health.

In the current era when people are striving for green living and sustainable development, the choice of building materials has

become a crucial aspect in the topics of environmental protection and health. Recently, synthetic roof underlayment has stood

out with its remarkable environmental and health advantages, forming a sharp contrast with traditional asphalt felt.

Research shows that synthetic roof underlayment does not contain a large amount of asphalt. This characteristic leads to a

significant reduction in the release of volatile organic compounds (VOCs), thereby greatly reducing the generation of odors.

This not only means the disappearance of pungent odors during the installation process, but more importantly, it creates a

healthier indoor and outdoor environment for installers and residents, effectively reducing the potential harm of harmful gases

to the human respiratory and nervous systems. It is worth mentioning that some synthetic roof underlayment products are

recyclable, which perfectly aligns with the current development concept of green buildings and provides strong support for the

sustainable development of the construction industry.

On the contrary, the asphalt component in traditional asphalt felt will gradually release unpleasant odors and VOCs with potential

health risks during the usage process. Long-term exposure to such an environment may cause chronic damage to human health.

From the perspective of the entire life cycle from production to disposal, the environmental footprint of asphalt felt is rather heavy.

Its production process consumes a large amount of energy and emits greenhouse gases. And at the end of its service life, due to its

material properties, it is difficult to recycle it efficiently and it often becomes construction waste that is hard to handle, bringing potential

pollution risks to soil and water sources and exacerbating the environmental burden.

By comparison, the advantages of synthetic underlayment in terms of environmental protection and health are obvious. While

reducing the health risks to installers and residents, it also contributes to the ecological environment of the earth. With the

continuous improvement of the public's awareness of environmental protection and health, as well as the construction industry's

continuous pursuit of sustainable development, synthetic roof underlayment is expected to gradually replace traditional asphalt

felt and become the mainstream choice for roof underlayment in future buildings, opening a new chapter of environmental protection

and health in the field of building materials and leading us towards a greener and more livable living and working space.

2024-12-30

DETAIL

A key line of defense for home health and building safety

In the field of building maintenance, the anti-mildew problem of roof liner is getting more and more attention. Recently, with a series of

home damage and residential health problems caused by moldy roof liners, this previously insignificant component of building construction

has been pushed to the forefront of public attention.

The roof liner, as an important barrier in the roof system to isolate the outside water vapor and the interior space, once it is attacked by

mold, the consequences are unimaginable. From the point of view of the structural integrity of the building, the growth of mold will

gradually erode the liner material, making it less strong, and over time, may lead to leakage on the roof. This will not only damage the

ceiling, wall decoration and furniture inside the house, but more seriously, continuous leakage may further affect the load-bearing

structure of the house, endangering the safety and stability of the entire building.

The health of the occupants is also closely linked to the mildew protection of the roof liner. As mold grows, it releases a large number of

spores and mycotoxins, which are dispersed in the air and easily inhaled by the human body, causing a range of health problems, such

as respiratory allergies, asthma attacks, headaches, fatigue and skin allergies. Especially for the elderly, children and people with low

immunity, long-term exposure to mold pollution in the environment, the health risk is multiplied.

So, what exactly causes the roof liner to be prone to mold? Humid weather conditions are one of the primary factors. In rainy, high

humidity areas, the roof is in a wet state for a long time, if the roof drainage system is not smooth, the water will penetrate into the liner,

providing an ideal breeding ground for mold growth. In addition, poor ventilation on the roof can also exacerbate the problem. The lack

of sufficient air circulation makes it difficult for the liner to dry quickly after wet, and the water vapor accumulates for a long time,

promoting the propagation of mold.

In order to effectively prevent the roof liner mold, the construction industry and owners are actively taking a variety of measures. In the

building design and construction phase, it is very important to strengthen the waterproof design of the roof. Ensure that the roof has a

suitable slope so that rainwater can quickly drain away from the roof surface, reducing the possibility of water infiltration. At the same

time, optimize the roof ventilation system, install enough vents to promote air circulation and reduce the humidity inside the roof.

For built homes, regular roof inspections and maintenance are key. The owner should arrange professional personnel to inspect the

roof at least every year, timely clean up the debris on the roof, repair the damaged drainage pipes and waterproof sealing parts, and

ensure that the roof is in a good waterproof state. Once the roof liner is found to have slight signs of mold, immediate measures should

be taken to deal with it, such as cleaning with a professional anti-mold cleaner, and improving the ventilation and drying conditions of

the roof to prevent further spread of mold.

In terms of material selection, the construction market is also constantly innovating. The new type of roof liner material has better moisture

resistance and mildew resistance, such as some composite materials containing mildew protection agents, which can effectively inhibit the

growth of mold. The application of these new materials provides more options for solving the mildew problem of roof liners at the source.

With the continuous improvement of people's awareness of living environment quality and building safety, roof liner anti-mildew is no

longer a small problem that can be ignored. It requires the joint efforts of all aspects of the construction industry from design,

construction to maintenance, and also requires owners to be vigilant and strengthen daily inspections and maintenance. Only in this

way can we ensure that the roof liner plays its due role, providing a dry, safe and healthy environment for our home life, away from the

threat of mold, so that every family can live under a stable roof.

2024-12-28

DETAIL

The Green Champion of the Construction Industry

In the current process of the construction industry actively practicing the concept of sustainable development, roof synthetic underlayment,

as a crucial material, is playing an important role with its outstanding environmental performance, serving as a powerful support for the

green development of the construction sector.

The material composition of roof synthetic underlayment fully demonstrates the deep integration of environmental concepts. A large

amount of plant fiber extracts are used as the main raw materials. These fibers are sourced from sustainably managed forest

resources and the waste generated during agricultural production processes. This significantly improves resource utilization efficiency,

greatly reduces the damage to virgin forests, and contributes to the balance and stability of the ecosystem. Meanwhile, the entire

production process strictly adheres to the principle of no addition of harmful chemicals, keeping out harmful substances commonly

found in traditional materials such as formaldehyde and heavy metals. This ensures that a solid safety line is established for the

environment and human health at the production source, effectively avoiding potential pollution to the surrounding environment

caused by material production and use, as well as potential threats to the health of building users.

In terms of the production process, roof synthetic underlayment also has many remarkable features. Through the refined optimization of

the production process and the efficient application of advanced energy recovery systems, the energy consumption per unit of product

has been successfully reduced. Compared with the manufacturing processes of traditional similar products, its energy consumption has

been significantly decreased. This achievement not only reduces the dependence on fossil energy and cuts down greenhouse gas

emissions but also conforms to the global trend of low-carbon development, setting an example of energy conservation and emission

reduction in the building materials production field.

Throughout the entire life cycle of the product, the environmental advantages of roof synthetic underlayment continue to be demonstrated.

After it has completed its mission and enters the waste stage, with its unique biodegradable properties, it can gradually decompose under

natural conditions and finally return to the natural ecological cycle, completely solving the problem of traditional building materials

occupying land resources for a long time and causing environmental pollution after being discarded.

In addition to its environmental characteristics, the functional performance of roof synthetic underlayment is also remarkable. It has

excellent thermal insulation and heat preservation capabilities, which can effectively block the heat transfer through the roof and reduce

the energy consumption requirements of buildings. Whether it is reducing the cooling energy consumption in hot summers or the heating

demand in cold winters, it has a significant effect, greatly improving the energy efficiency of buildings. Moreover, its good flexibility and

durability enable it to adapt to a variety of complex roof structures and climatic conditions, providing long-term, stable, and reliable

protection for buildings and ensuring that buildings can maintain good performance under various environments.

In the applications of numerous actual construction projects, the advantages of roof synthetic underlayment are fully revealed. In

buildings of various scales and functions, after the installation of roof synthetic underlayment, the temperature stability of the indoor

environment has been significantly enhanced, effectively reducing the building's dependence on energy and making a substantial

contribution to energy conservation and emission reduction. At the same time, due to its outstanding environmental performance,

these buildings have stood out in the green building assessment system, winning high scores and praise, which has greatly improved

the overall quality, market value, and social image of the buildings. This successful example undoubtedly provides extremely valuable

references and lessons for other construction projects in terms of material selection and sustainable development practices, vividly

demonstrating the broad application prospects and huge potential of roof synthetic underlayment in the modern construction field.

With the continuous improvement of environmental standards in the construction industry and the growing popularity of the concept

of sustainable development, roof synthetic underlayment, with its dual advantages of environmental protection and performance, is

gradually becoming the mainstream choice in the building materials market. It continues to drive the construction industry towards a

more green, low-carbon, and sustainable direction, contributing an indispensable force to building an environmentally friendly

construction environment and leading the construction industry on a new journey of green development.

2024-12-27

DETAIL

The Invisible Guardian of Building Protection: MOUNTAIN BIGFOOT BARRIER Emerges

In the journey of the construction industry's continuous pursuit of excellence and innovation, there is such a "behind-the-scenes hero"

quietly rising. It is MOUNTAIN BIGFOOT BARRIER. Although not often known to the public, it has been silently safeguarding the safety

and comfort of buildings. Like an invisible guardian, it plays a crucial role at critical moments. Recently, it has emerged in the industry,

sparking widespread attention and discussion.

The construction industry has long faced numerous challenges. From the unpredictable extreme weather to the increasingly stringent

energy-saving standards, every link requires meticulous refinement and upgrading. However, traditional building protection methods

have gradually revealed various limitations when dealing with these complex situations. For example, in terms of resisting wind and

rain erosion, the protective performance of some traditional materials gradually declines over time, threatening the structural integrity

of buildings and the internal environment. In terms of improving energy efficiency, traditional insulation and heat preservation methods

also seem inadequate to meet the high requirements of modern buildings for energy conservation and emission reduction.

The emergence of MOUNTAIN BIGFOOT BARRIER is a powerful response to these challenges. It uses a series of advanced technologies

and unique material combinations to create a solid and efficient protective barrier for buildings. Whether it is the baptism of wind and

rain or the test of scorching sun and severe cold, it can rely on its excellent performance to stick to its post and ensure that the interior

of the building always remains stable and comfortable. Its excellent quality, verified through strict testing, not only greatly reduces the

risk of building damage caused by external factors but also provides key support for improving the overall energy efficiency of buildings.

At the same time, MOUNTAIN BIGFOOT BARRIER also fully considers the development trend of modern buildings in its design concept.

It adopts a lightweight and easy-to-install design, making the construction process more convenient and efficient and reducing the input

of labor and time costs. Moreover, from an environmental perspective, it adheres to the principle of sustainable development in the

selection of raw materials, using a large number of recyclable and pollution-free resources, contributing to the green transformation of

the construction industry.

As MOUNTAIN BIGFOOT BARRIER is continuously promoted and verified in practical applications, it is gradually changing the pattern

of the building protection field and leading the industry towards a more efficient, intelligent, and environmentally friendly new era.

Although it is not yet fully known to the public, it has already become the new favorite among many construction practitioners in the

professional field, painting a promising new picture for the future development of buildings.

2024-12-25

DETAIL

Synthetic Roof Underlayment: Stricter Standards, Longer Warranties, and Reshaping the Industry Landscape

In the field of building materials, the choice of roof underlayment plays a crucial role in the quality and lifespan of buildings.

Recent market research has shown that synthetic roof underlayment has significant advantages in terms of regulatory

compliance and warranty periods, forming a sharp contrast with traditional asphalt felts.

Synthetic roof underlayment is renowned for its high quality. It strictly adheres to international authoritative standards such

as ASTM and ICC-ES, and demonstrates excellent durability and performance. The warranty period, which can last as long as

15 to 50 years, clearly reflects the manufacturers' firm confidence in their products and provides consumers with reliable

long-term guarantees.

In contrast, although traditional asphalt felts can meet the basic requirements of the industry, their performance standards

are relatively low, the certification procedures are not strict enough, and the warranty periods are shorter, showing some

deficiencies in safeguarding consumers' rights and interests.

Amid this ebb and flow, synthetic roof underlayment stands out and has become the preferred choice for consumers by

virtue of its strict standards and long warranty periods. It will surely prompt the building materials industry to conduct

in-depth thinking on quality and after-sales guarantees and to carry out comprehensive upgrades, thus reshaping the

industry landscape.

2024-12-24

DETAIL

BIGFOOT 15

Learn More

BIGFOOT 15

Learn More

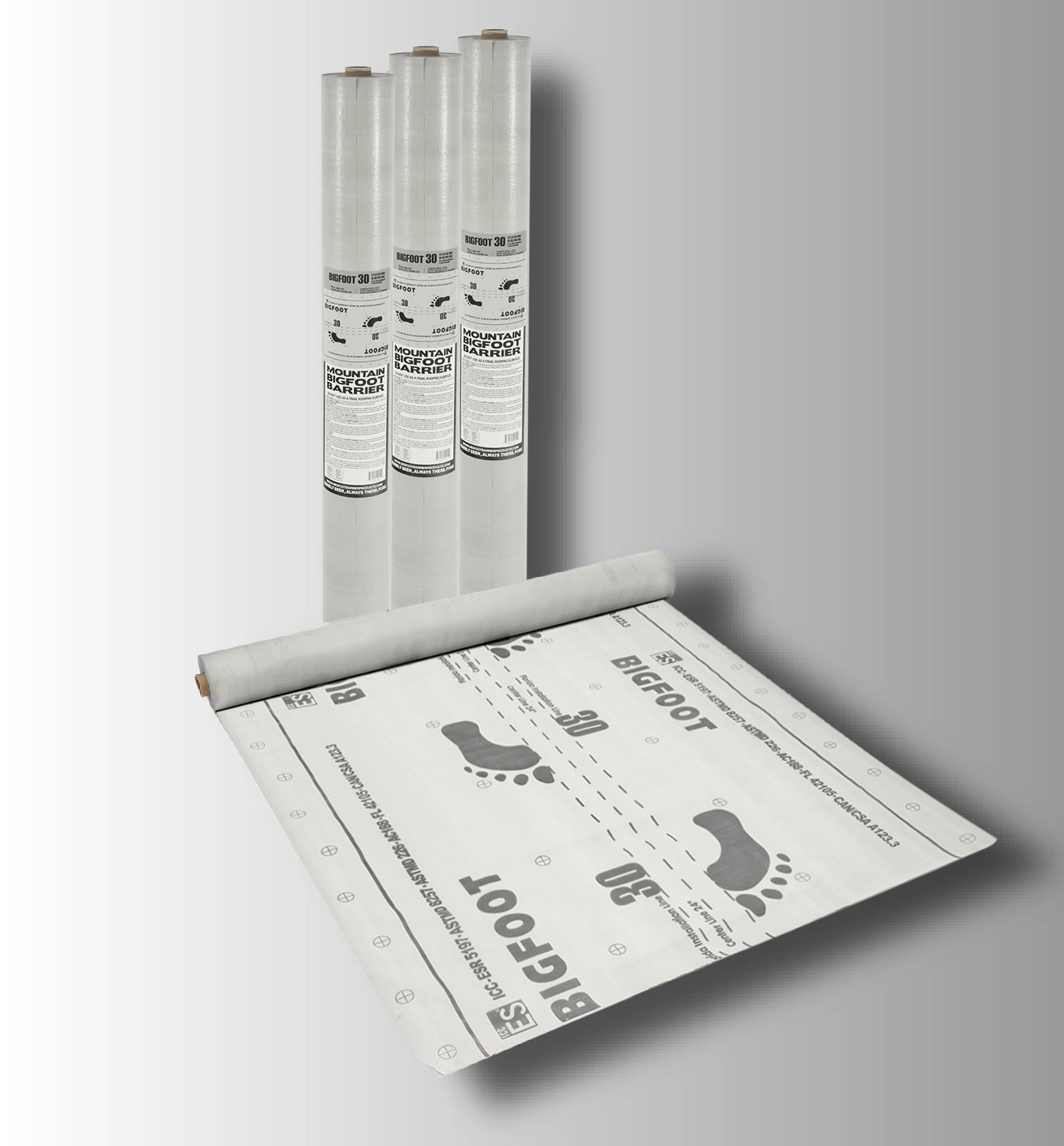

BIGFOOT 30

Learn More

BIGFOOT 30

Learn More

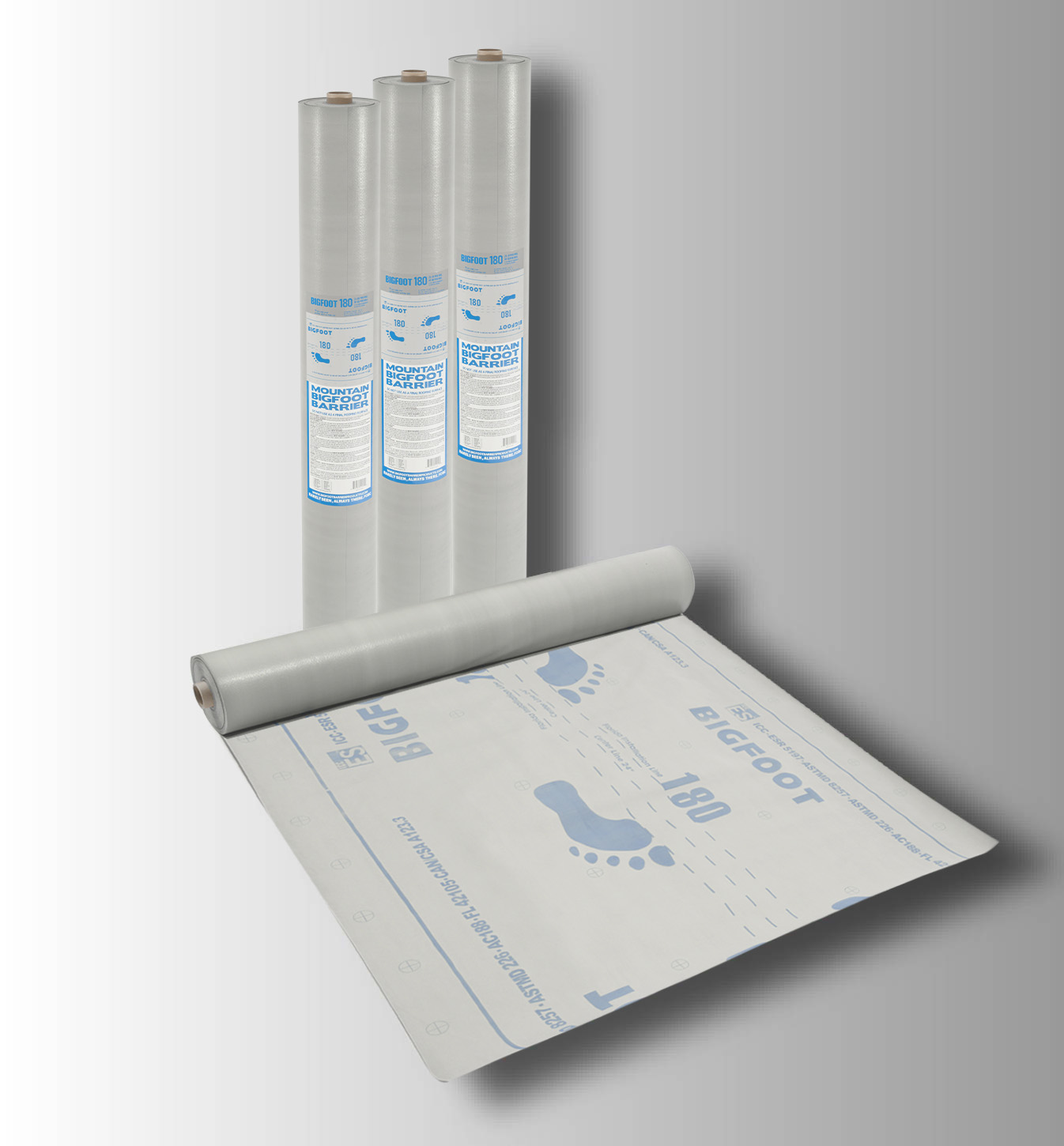

BIGFOOT 180

Learn More

BIGFOOT 180

Learn More

BIGFOOT HD

Learn More

BIGFOOT HD

Learn More

BIGFOOT 15

BIGFOOT 15

BIGFOOT 30

BIGFOOT 30

BIGFOOT 180

BIGFOOT 180

BIGFOOT HD

BIGFOOT HD

Back

Back